Bearing arrangement

A facility and bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of increased wear risk, increased wear risk of hydraulic sealing system, etc., and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

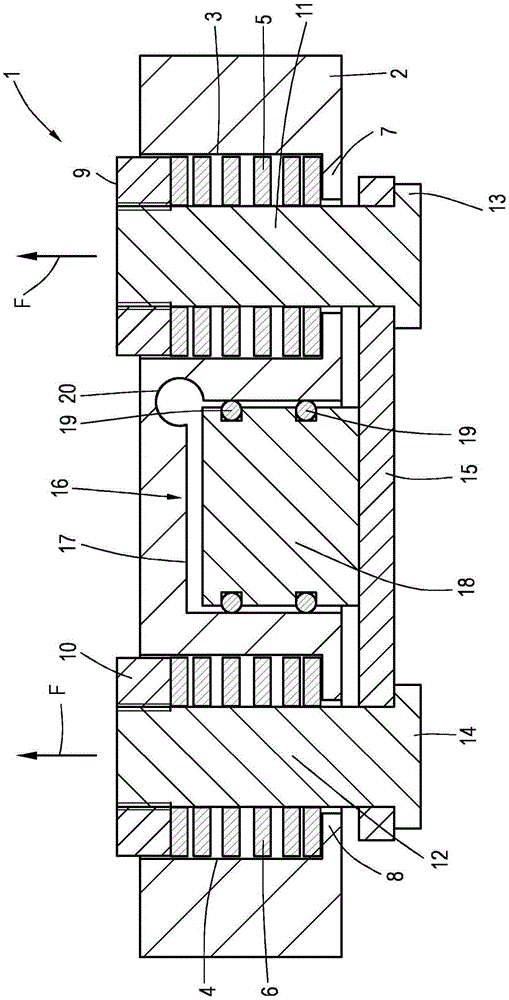

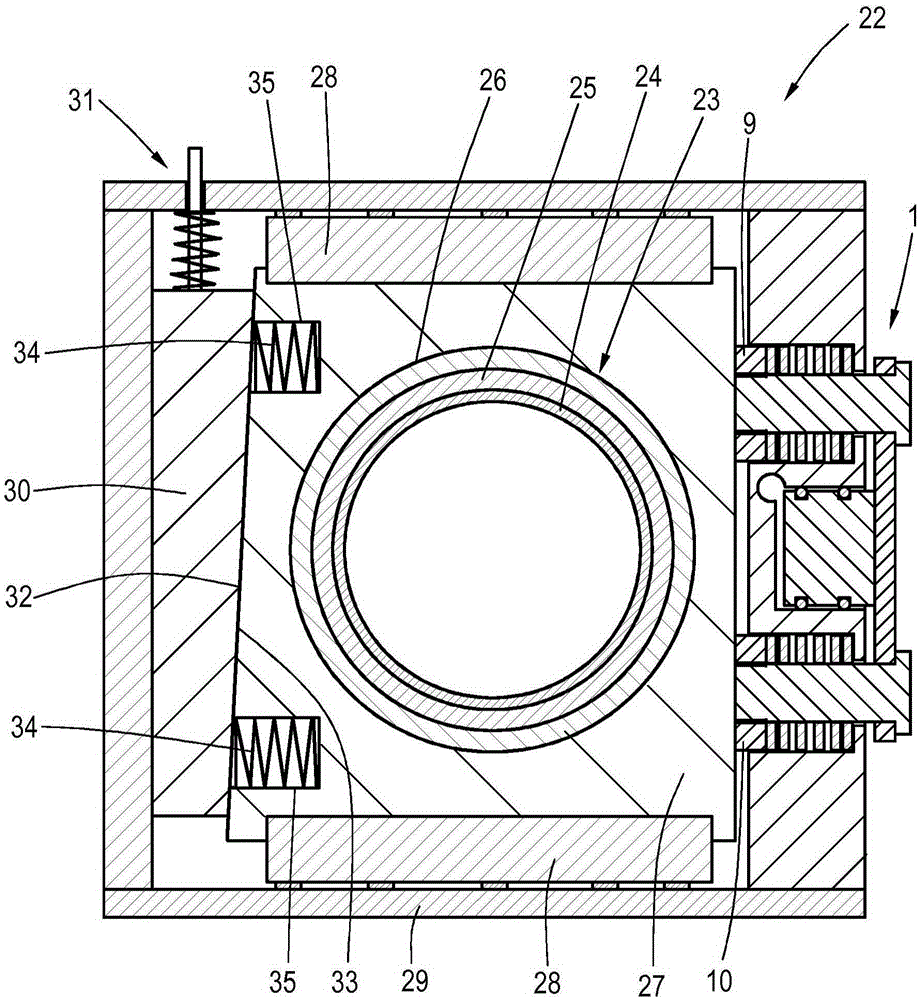

[0019] figure 1 An adjusting device 1 according to the invention is shown, which comprises a housing 2 in which, in the exemplary embodiment shown, two cylindrical receptacles 3, 4 are arranged, in which are respectively accommodated Spring elements 5,6. These are high-efficiency springs with rectangular coil cross-sections, which can generate high adjusting forces. The springs are supported with one end on the respective bases 7 , 8 of the recesses 3 , 4 . They are supported at the other end on pressure pieces 9 , 10 which are respectively arranged on bolts 11 , 12 arranged in receptacles 3 , 4 , in particular screwed thereon. The spring elements 5 , 6 are pretensioned, and they make it possible to exert a pressing force, as indicated by the two arrows F, on the pins 11 , 12 together with the piston disks 9 , 10 , which push them out of the housing 2 . Press outward. A bearing housing is associated with these two pins 11 , 12 together with the piston disks 9 , 10 , in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com