Manufacturing method and manufacturing apparatus of laminated battery, laminated battery

A manufacturing method and battery technology, which are applied in the manufacture of secondary batteries, small-sized batteries/batteries, and electrode manufacturing, can solve problems such as difficult continuous production methods, and achieve the effects of excellent productivity and excellent manufacturing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

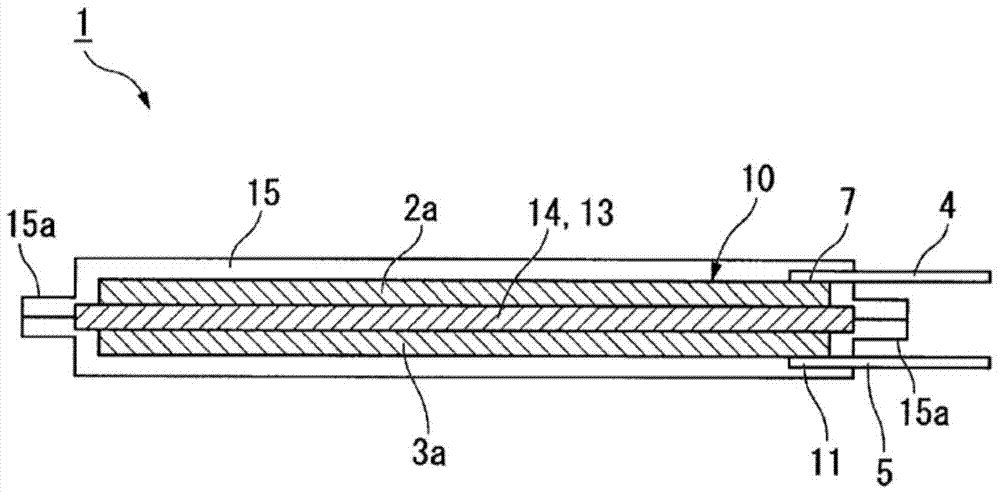

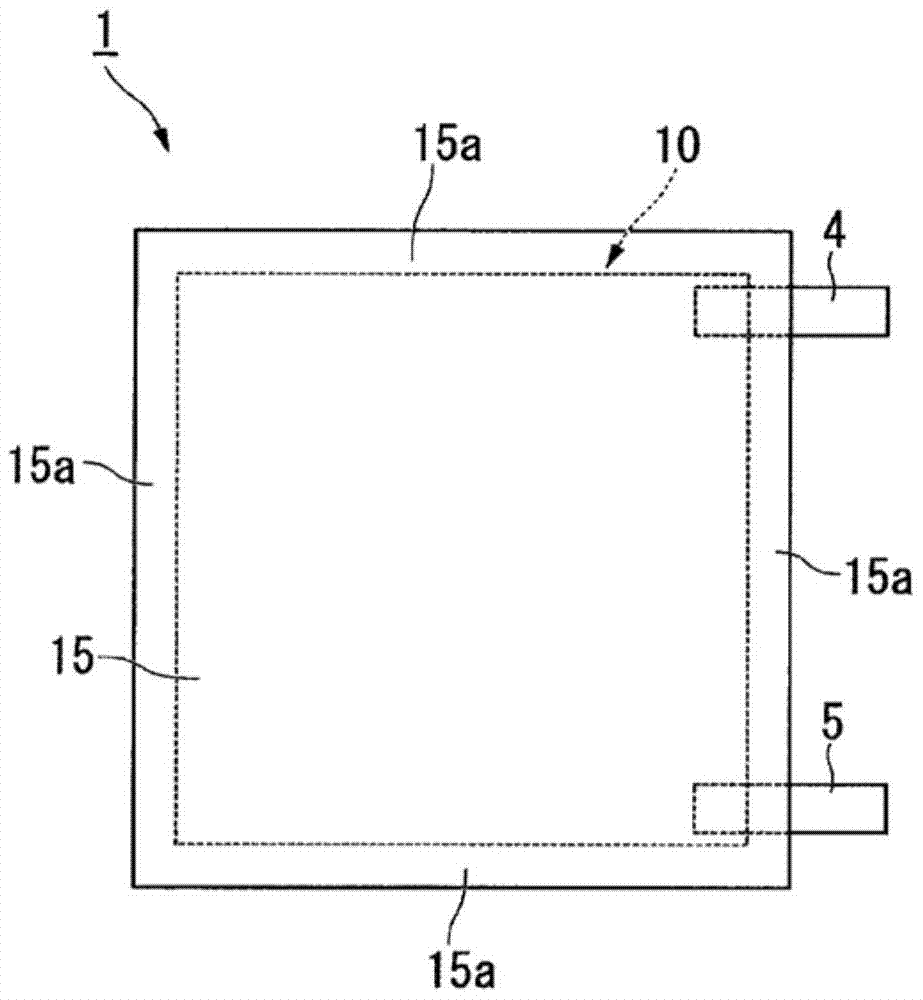

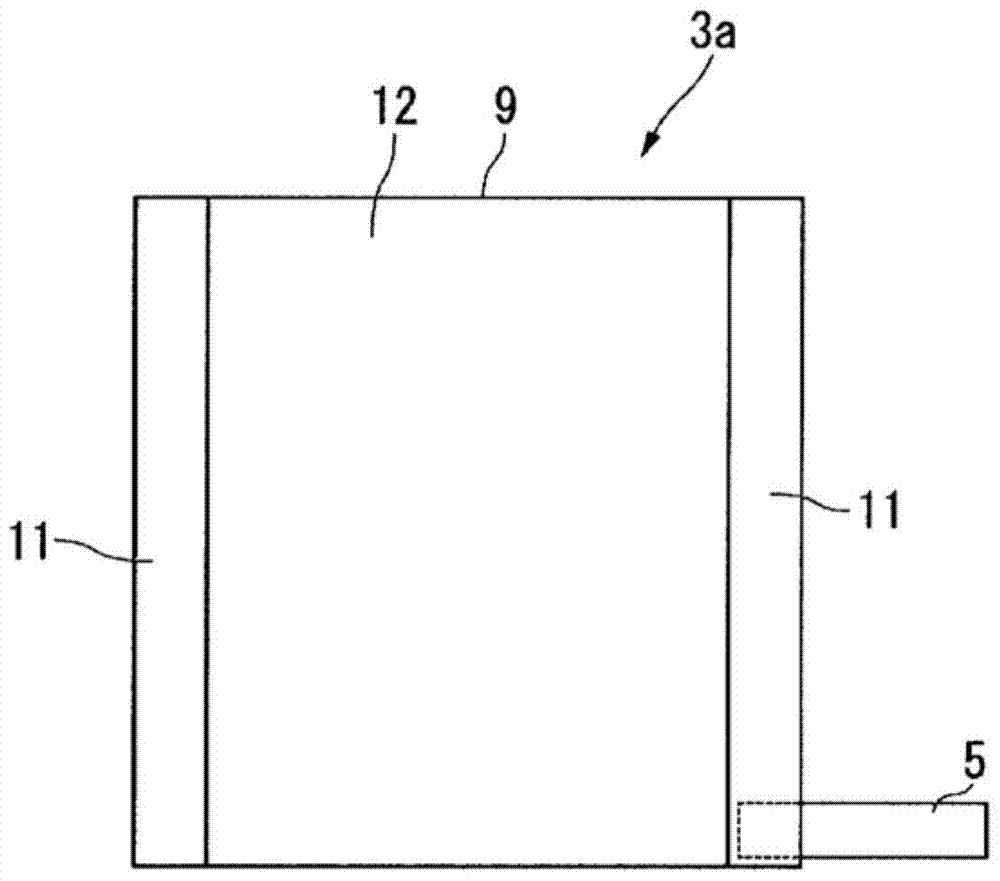

[0081] Hereinafter, embodiments of the method and apparatus for manufacturing a laminated battery according to the present invention, and the laminated battery obtained therefrom will be described with reference to the drawings. In addition, in this embodiment, a lithium ion secondary battery is mentioned as a laminated battery, and it demonstrates below.

[0082]

[0083] figure 1 is a cross-sectional view showing a lithium-ion secondary battery (laminated battery) manufactured by a manufacturing method according to an embodiment of the present invention, figure 2 yes figure 1 A plan view of the lithium-ion secondary battery shown.

[0084] Such as figure 1 As shown, the multilayer membrane electrode assembly 10 included in the lithium ion secondary battery (laminated battery) produced by the production method of this embodiment has positive electrode plates (electrode plates) 2a and negative electrode plates (electrode plates) 3a alternately layered. The terminal tab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com