Electric atomizer

An electric sprayer and battery technology, which can be used in devices, applications, animal husbandry, etc. to capture or kill insects, and can solve problems such as circuit failure, many inserts, and the influence of the circuit structure of the sprayer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

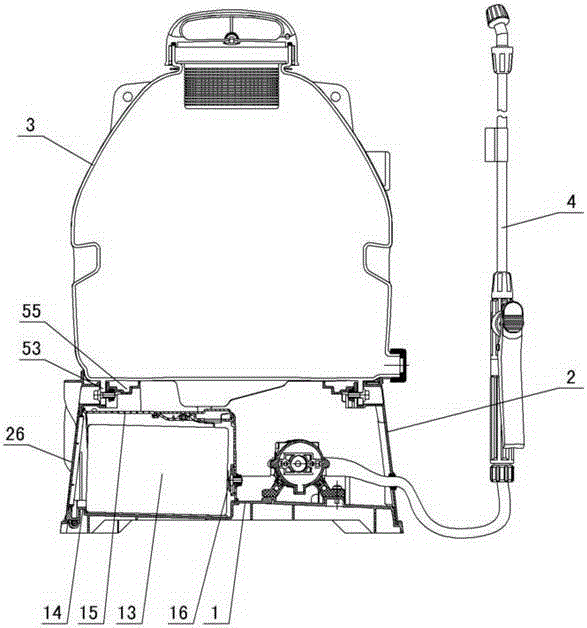

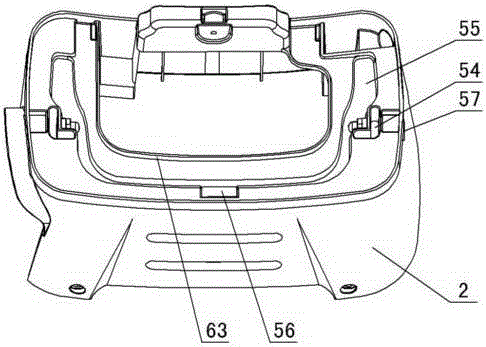

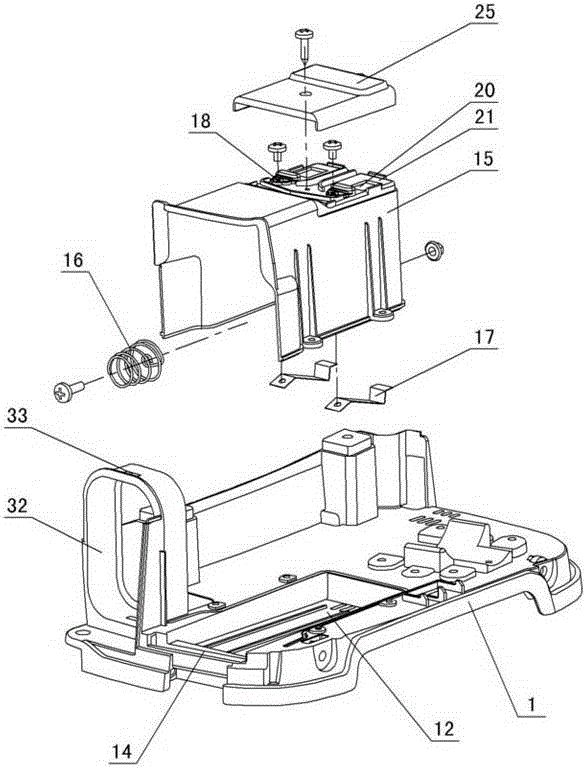

[0017] The present invention relates to an electric sprayer, such as figure 1 — Figure 10As shown, it includes a base 1, a base upper cover 2, a medicine barrel 3 and a spray gun 4. It is characterized in that: the base 1 is provided with a storage battery 13, and the base is located on the front side of the storage battery. The side is in contact with each other, and the base is located on the battery to set the battery box cover 15, the outer wall of the battery box cover is fixed with the base 1 by fasteners, the battery reed is set on the battery box cover, and the ejection spring is set on the inner wall of the back side of the battery box cover 16. The battery reed and the ejection spring are in contact with the battery 13. A card frame 32 is formed on the base 1, and a card slot 33 is formed on the card frame. A switch card seat 34 is set in the card frame, and the outer wall of the switch card seat is made of Grab hook 35, grab hook and draw-in groove match, and open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com