a non-stick pan

A non-stick, irregular technology, applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of high production cost, damage to the bottom of the pot, low service life, etc., to reduce the contact friction area, improve The overall non-stickiness, the effect of reducing energy consumption and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

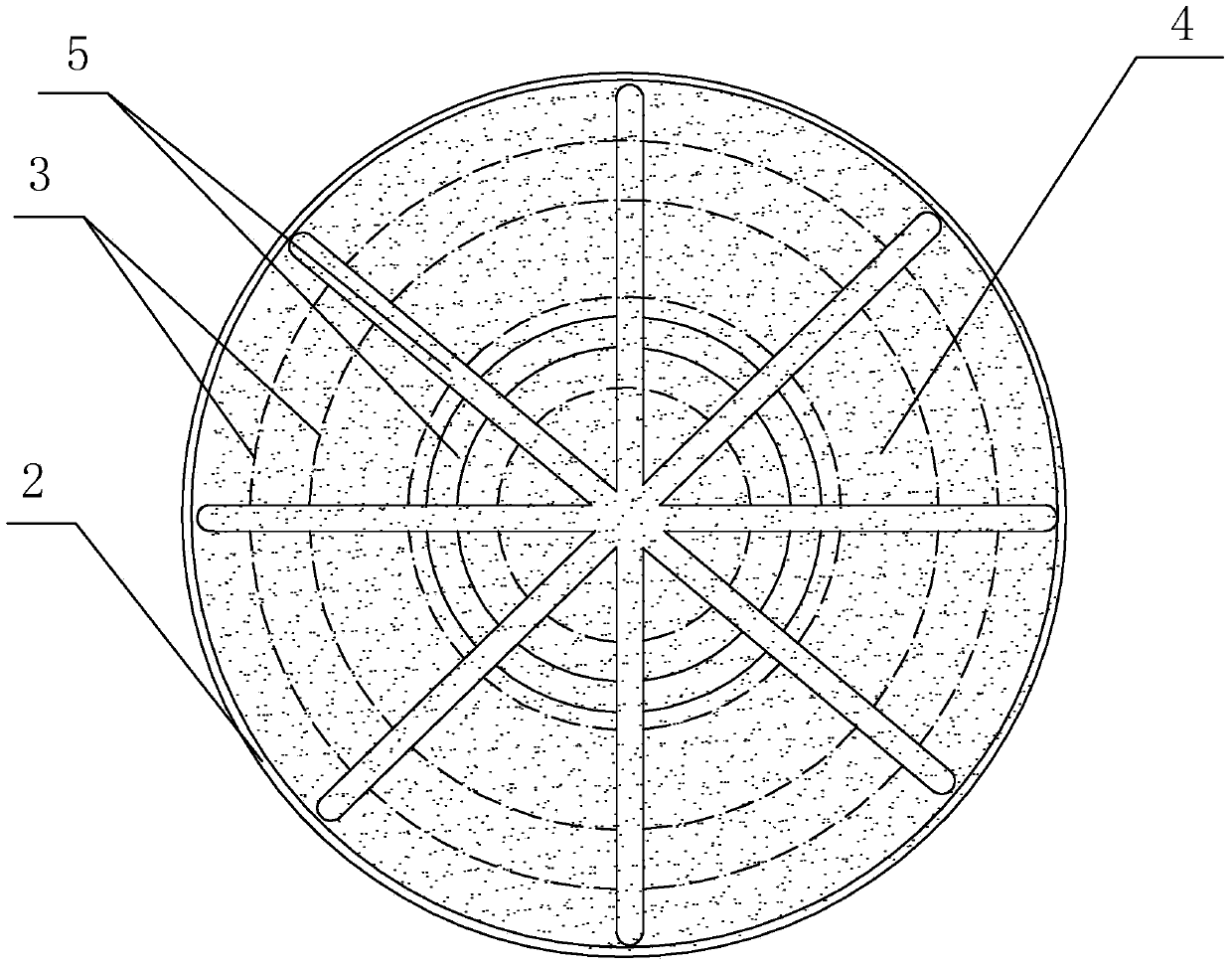

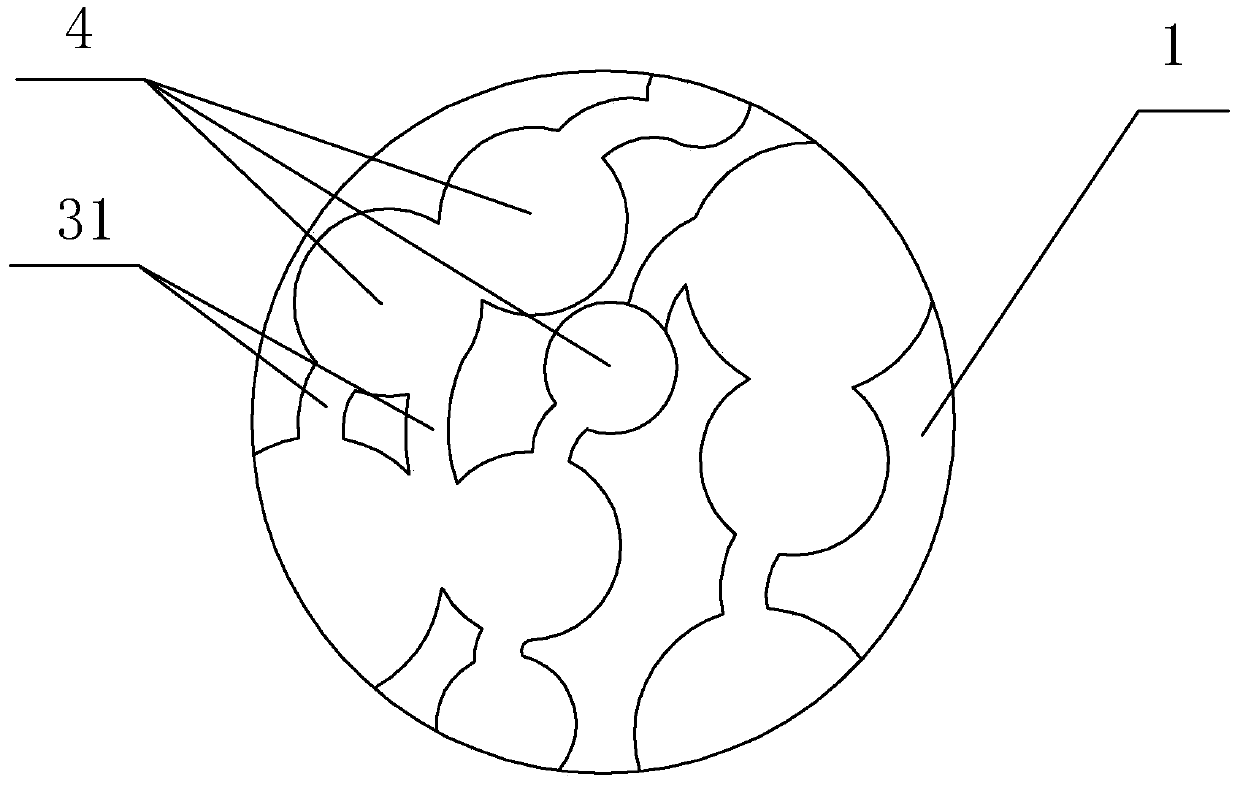

[0037] As shown in the figure, a non-stick pan, in which 2 in the figure is marked as a non-stick pan. Arc-shaped shallow grooves 3 are scattered irregularly on the bottom of the pot 1, figure 2 The number 3 in the middle is the schematic structure of the arc-shaped shallow groove 3. The arc-shaped shallow groove 3 is formed by a group of alloy steel particles with an equivalent diameter of 0.3-1.3mm impacting the rotating pan bottom 1;

[0038] On the basis of forming the arc-shaped shallow groove 3, the bottom of the pot 1 is irregularly scattered with pits 4, and the pits are impacted by a group of alloy steel balls with a diameter of 1 to 4 mm on the stationary bottom of the pot. 1, the groove of the arc-shaped shallow groove 3 is smaller than the diameter of the pit, so that the overlap of the arc-shaped shallow groove 3 and the pit 4 is covered by the pit 4, and the gap between the pits is formed The connecting groove 31, such as figure 2 shown in . The inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com