A pressure-controlled electric pressure cooker

An electric pressure cooker and pressure technology, used in pressure cookers, cooking utensils, household appliances, etc., can solve the problems of small elastic deformation and low pressure control accuracy, and achieve increased structural strength, good pressure signal transmission, and easy induction of pressure changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

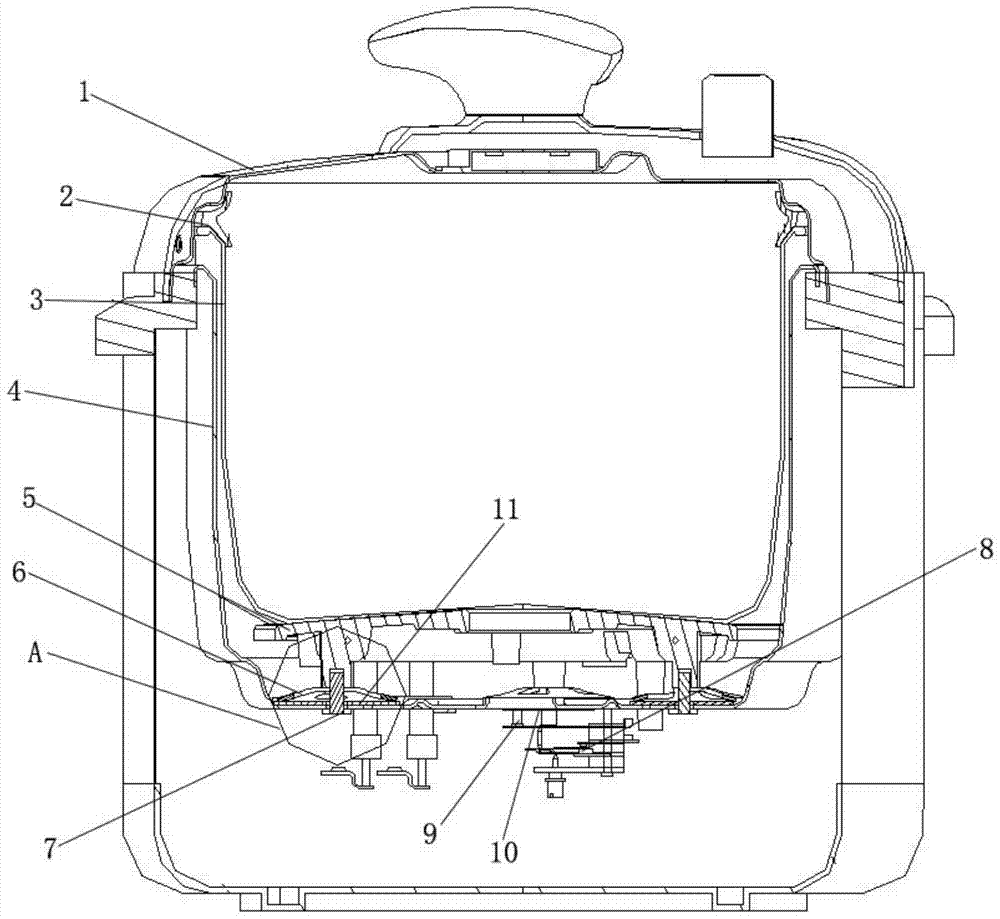

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

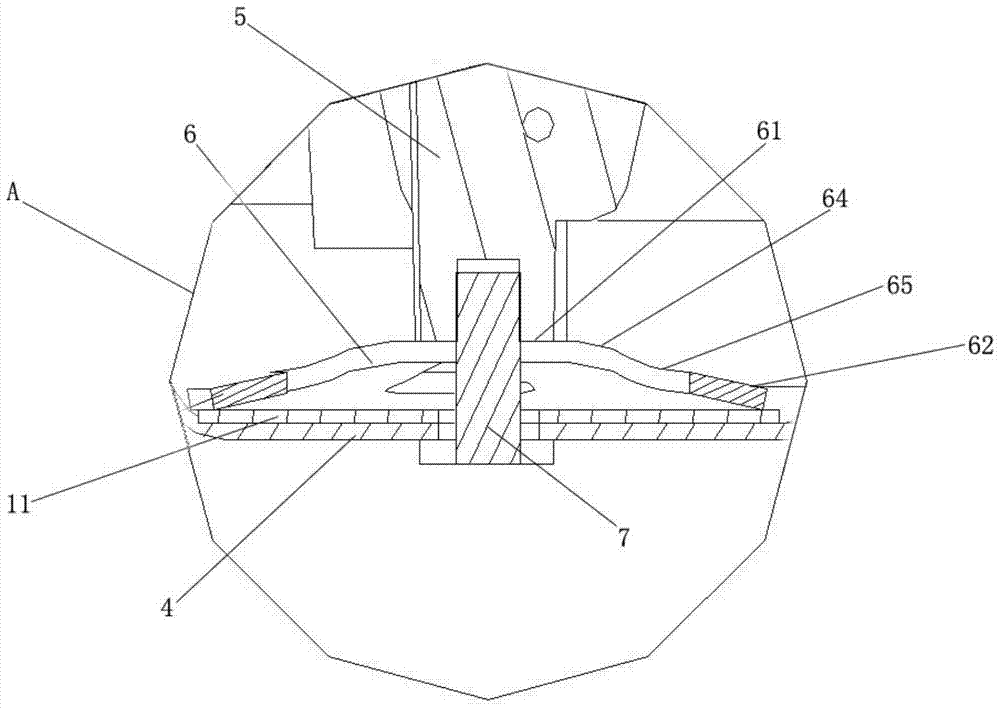

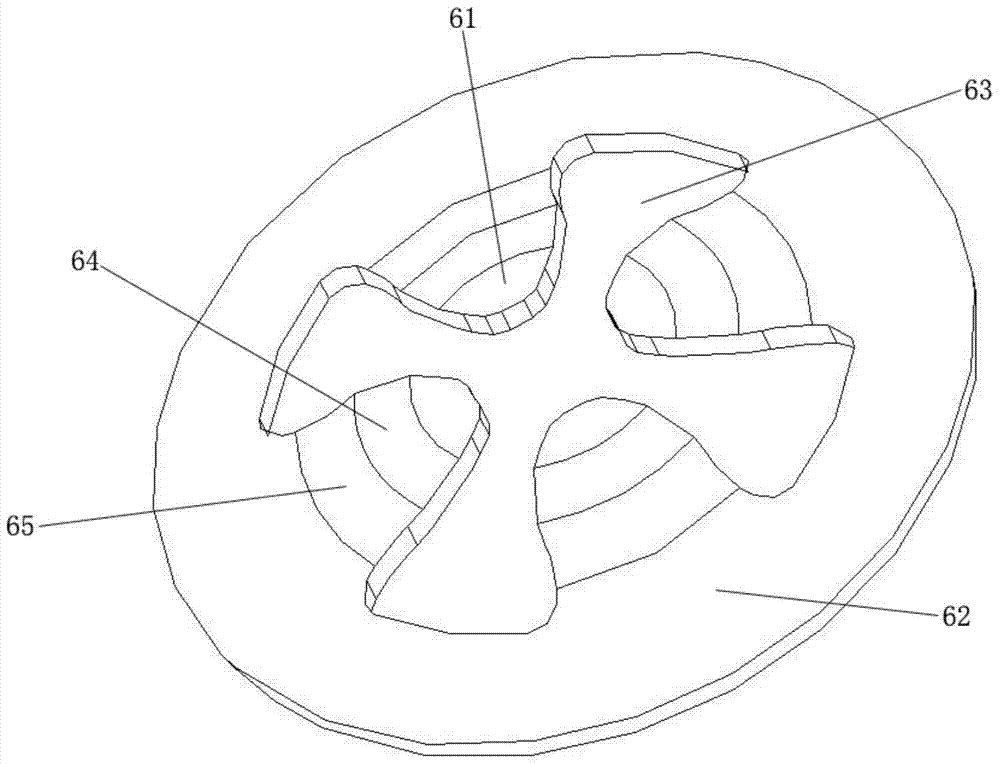

[0025] Such as figure 1 As shown in the structural diagram of the pressure control type electric pressure cooker of the present invention, it includes a pot cover 1, a sealing ring 2, an inner pot 3, an outer pot 4, a heating plate 5, and several pots arranged between the heating plate 5 and the outer pot 4 The elastic component and the pressure detection device arranged under the outer pot 4, the heating plate 5 and the pressure detection device are connected with the control circuit board, and the elastic connection between the outer pot 4 and the inner pot 3 is realized by the elastic part, and the pressure of the inner pot 3 is adjusted. The displacement is converted into the pressure displacement of the outer pot 4, and the pressure detection device transmits a signal to the control circuit board to control the heating plate 5 to start heating or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com