Energy storage spot-welding locating and clamping device of stationary blade fan-shaped block welding assembly

A technology for welding components and clamping devices, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve problems such as affecting the structure and quality of components, difficult to remove sheets and parts, affecting appearance, etc., to improve welding quality, reduce Scrap rate, saving effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

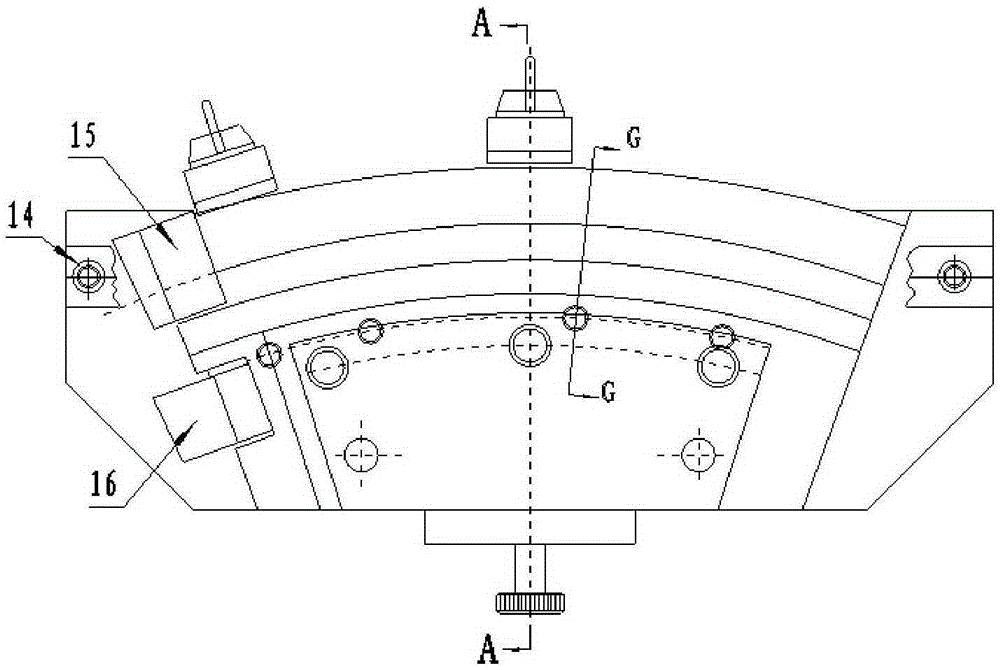

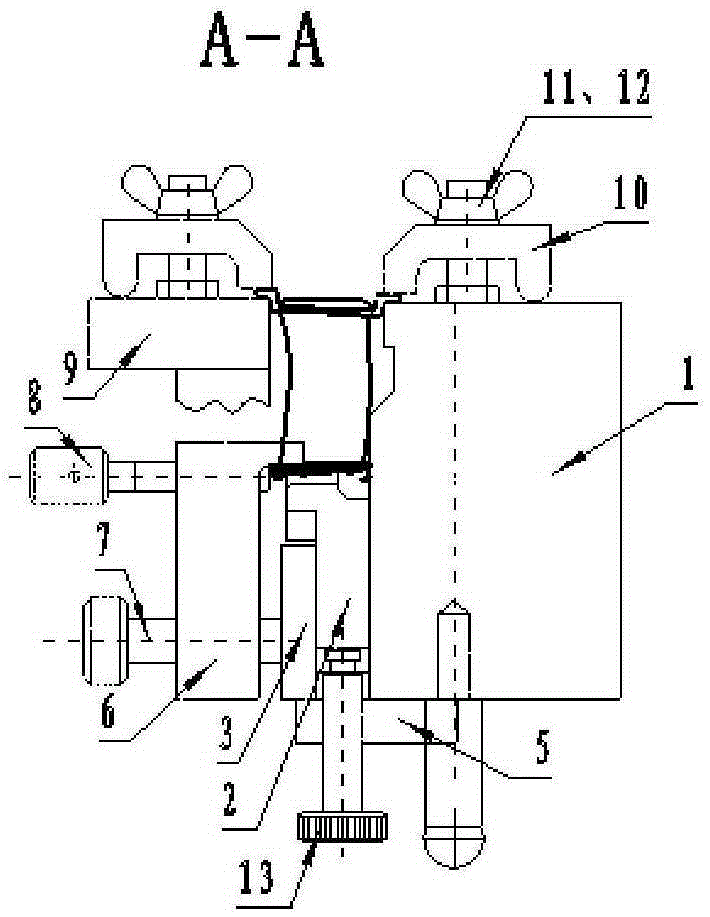

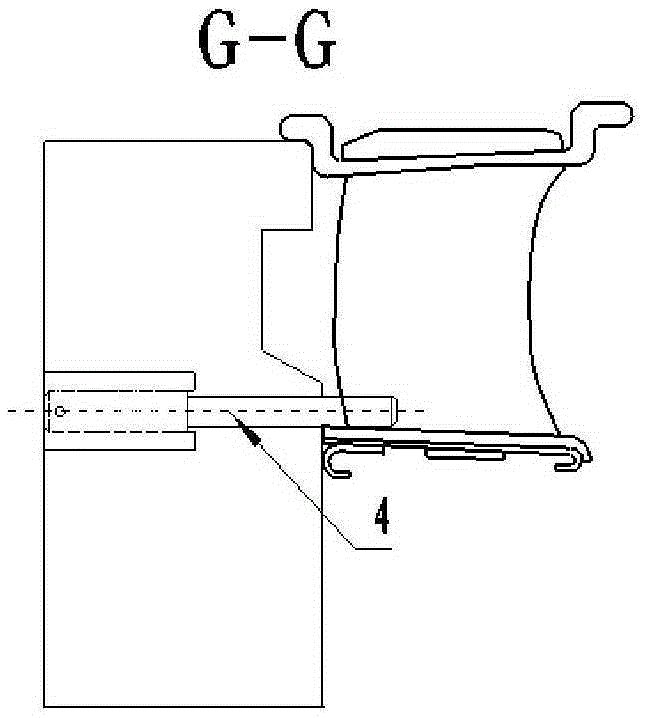

[0029] Such as Figure 1a-Figure 1c As shown, the energy storage spot welding fixture is mainly composed of base 1, pressure block 2, guide plate 3, stop pin 4, support plate 5, positioning block 6, first screw 7, second screw 8, support 9, pressure plate 10, screw The column 11, the nut 12, the third screw 13, the cylindrical pin 14, the first positioning block 15 and the second positioning block 16, all positioning blocks, pressure blocks, etc. can be flexibly disassembled, each component such as Figure 2a , Figure 2b , Figure 3a , Figure 3b , Figure 4a , Figure 4b , Figure 5a , Figure 5b , Figure 6a , Figure 6b Shown.

[0030] Such as Figure 2a-Figure 2b As shown, the base 1 is made into an arc-shaped positioning surface according to the structure of the intake side of the module. The positioning support 9 for the exhaust side of the module is fixed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com