Semi-automatic mixing and dispensing line for bonding agent and molding material for ceramic bonded abrasive tools

A technology for consolidating abrasive tools and molding materials, which is applied in the direction of grinding devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of excessive dispersion, labor and time-consuming, low efficiency, etc. Simple process and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

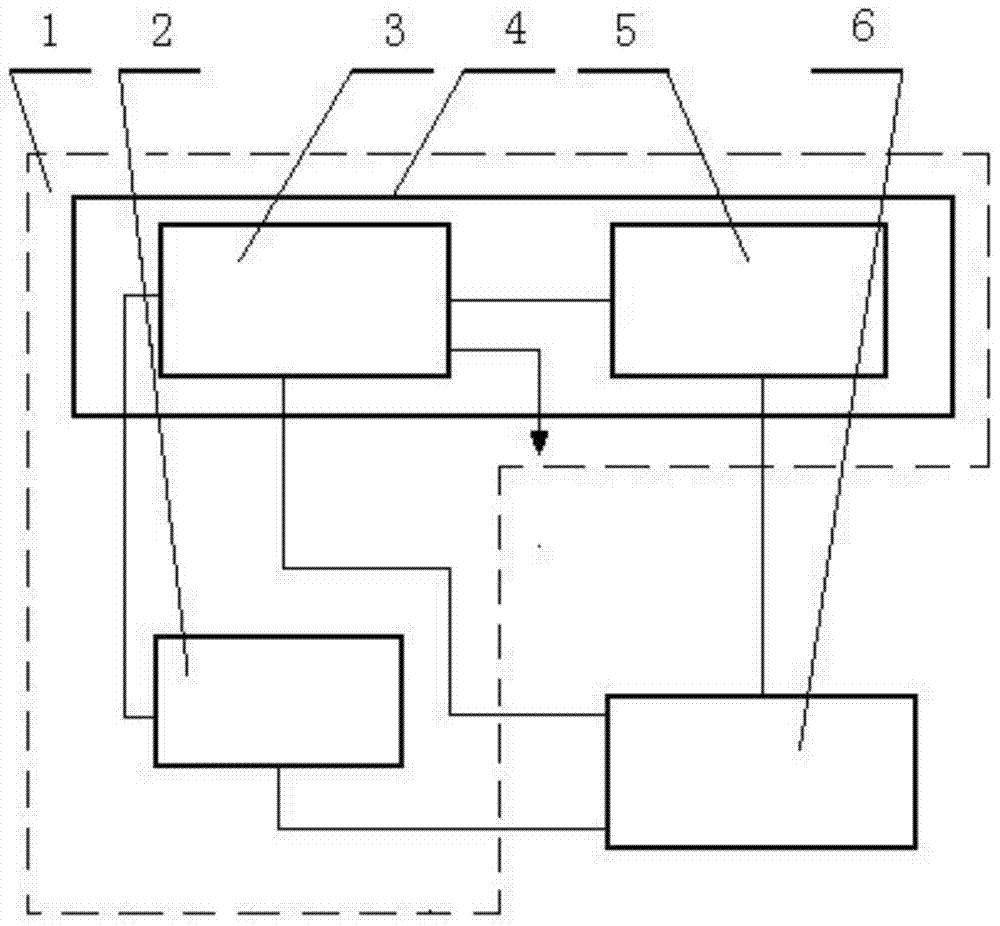

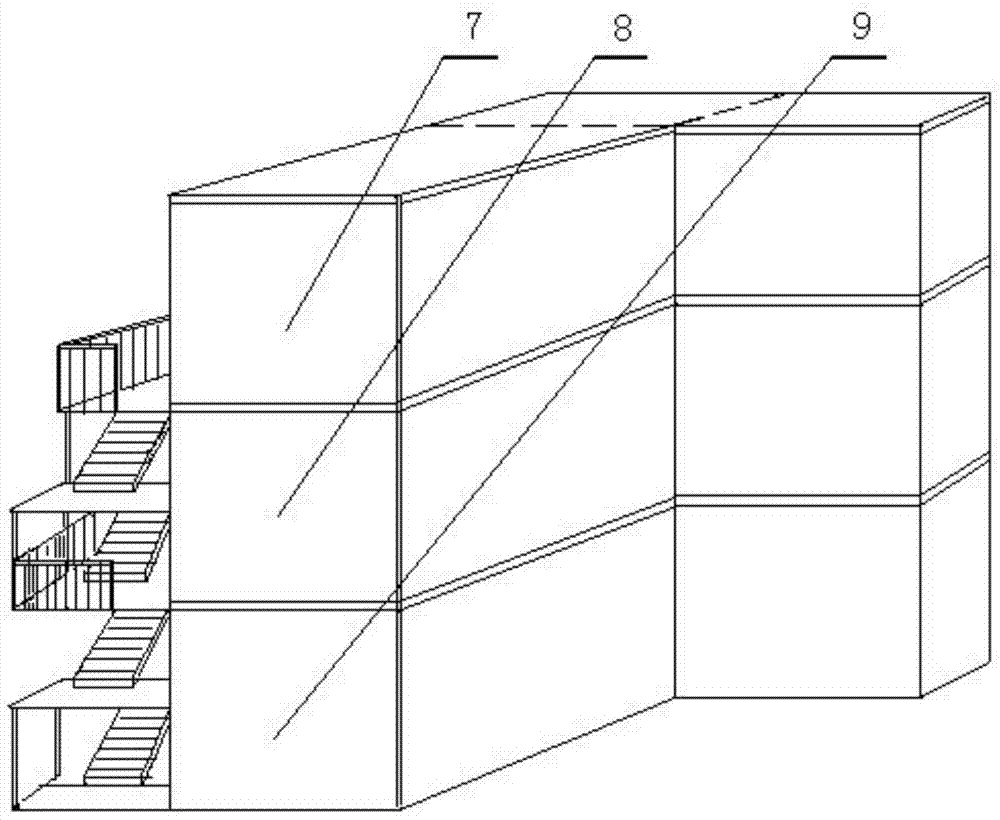

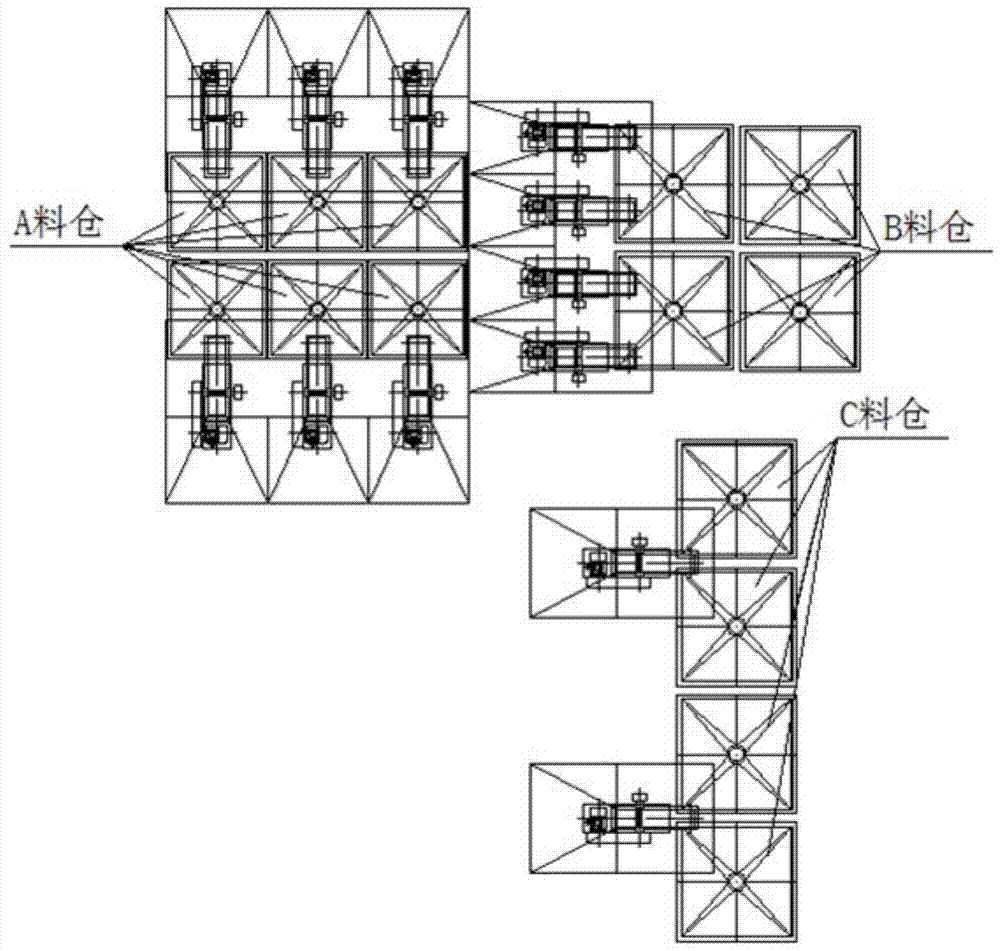

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention includes a control system 6, a molding material batching system 4, a binder batching system 2 and a frame structure 1, and the frame structure 1 is used to install the binder batching system 2 and the molding material batching system 4; the frame structure 1 adopts a three-layer frame structure. The shape of each layer plane of the three-layer frame structure is an L shape. The three-layer frame structure includes an upper layer, a middle layer and a bottom layer. The upper layer is the silo layer 7, the middle layer is the metering layer 8, and the bottom layer is the mixing layer 9. Foundation pits are arranged around the three-layer frame structure, and the foundation pits are located below the ground level. The control system 6 includes a display screen and an operation console; the operation console is installed outside the frame structure 1 . The frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com