Manipulator for clamping dripping hopper component

A technology of manipulators and dropping funnels, applied in the direction of manipulators, chucks, catheters, etc., can solve problems such as inconvenient gripping, and achieve the effect of preventing upward movement from deviating from the position and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

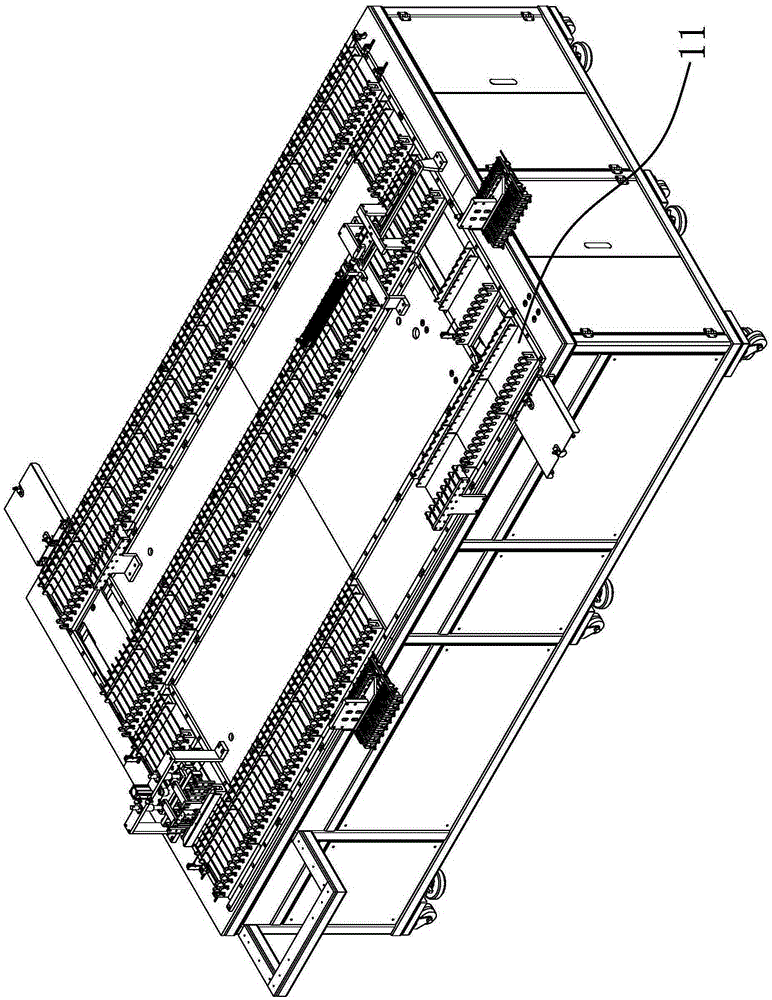

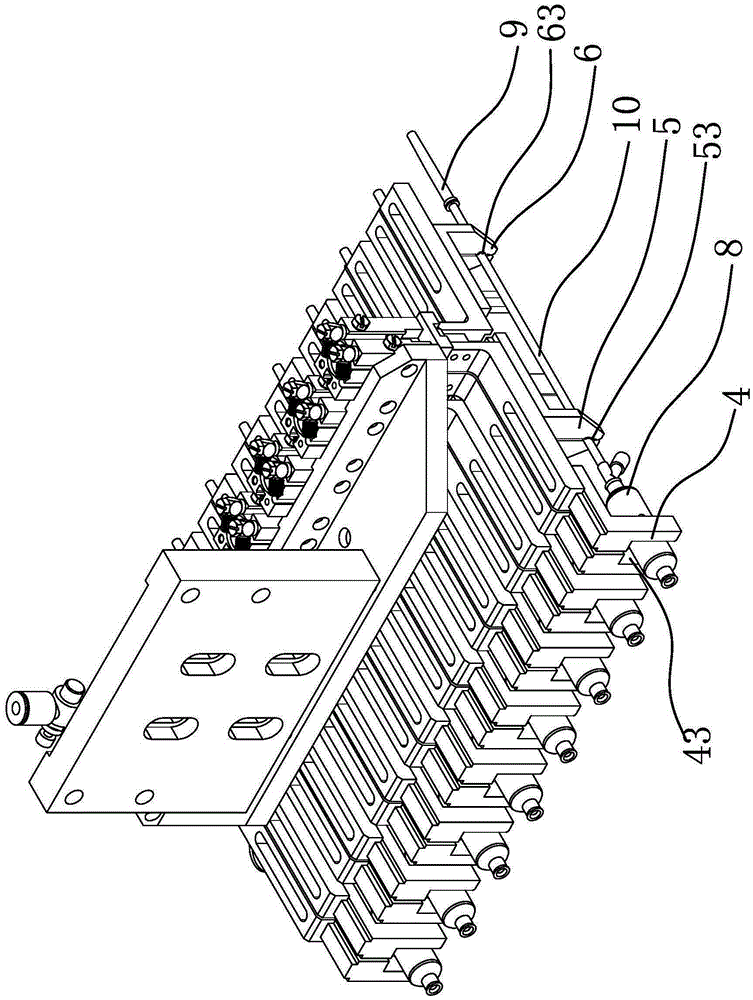

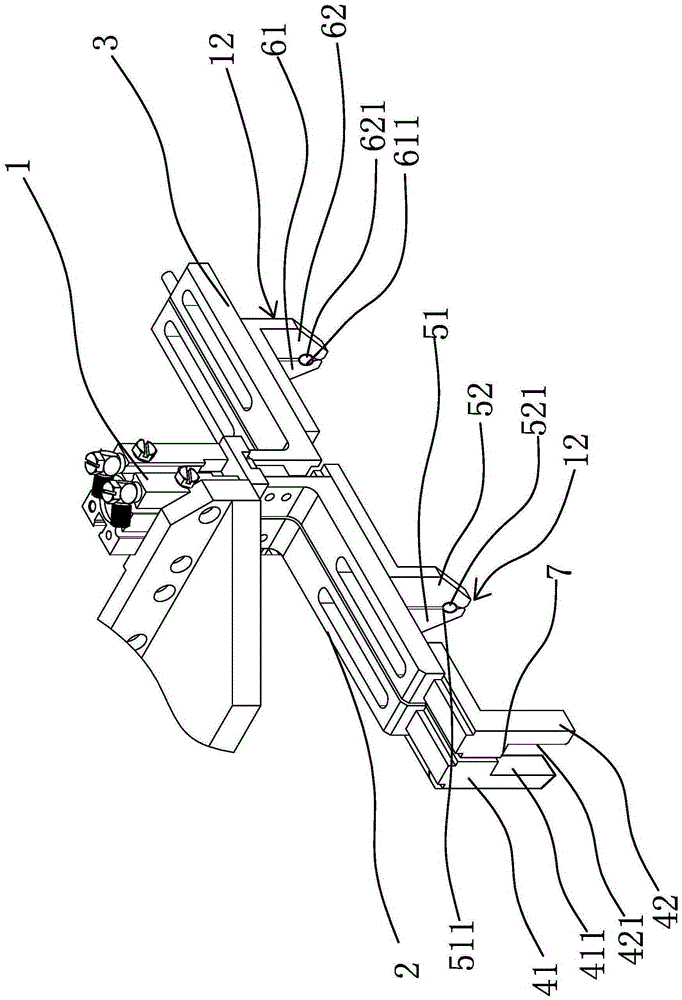

[0029] Such as Figure 1 to Figure 3 As shown, the manipulator in this embodiment includes a driver 1 and a drip funnel chuck 4 and a conduit chuck 12 that are connected to the driver 1 and arranged at intervals, and there are two conduit chucks 12, which are respectively conduit chuck-5 And conduit chuck two 6. The driver 1 can drive the chuck 4 of the dropping funnel, the first 5 of the conduit chuck 5 and the second 6 of the conduit chuck to be clamped or opened at the same time. The dripping funnel chuck 4 includes the first dripping funnel clamping arm 41 and the second dripping funnel clamping arm 42, and the first dripping funnel clamping arm 41 and the second dripping funnel clamping arm 42 can form a joint for clamping the dripping funnel 8 when they are clamped. The clamping mouth one 43; the conduit chuck one 5 includes the conduit clamping arm one 51 and the conduit clamping arm two 52 which are arranged oppositely, and the conduit clamping arm one 51 and the cond...

Embodiment 2

[0037] This embodiment is roughly the same as Embodiment 1, except that the limiting structure 7 in this embodiment is a protruding post, and the protruding post is arranged laterally on the side wall of the first 41 of the dripping funnel clamp arm and / or the second dripping funnel clamping arm. 42 on the side wall. Specifically, the protruding post can be horizontally arranged on the side wall of the dripping funnel clamp arm one 41; it can also be horizontally set on the side wall of the dripping bucket clamp arm two 42; The protrusions are arranged on the side wall and the side wall of the second clamp arm 42 of the dropping funnel, and the two protrusions are directly opposite to each other. In this embodiment, any one of the above three methods can be used to realize the position-limiting function.

[0038] In other embodiments, there may be one or more than two conduit clamps, such as three, four, etc., the number and position of which may be selected and set according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com