Inverted-V-shaped clamping plate device of film blowing machine

A herringbone and film blowing machine technology, which is applied in the field of plastic film blowing machinery, can solve the problems of rough surface of wooden slats, large film friction coefficient, scratches on film surface, etc., and achieve low friction coefficient, small friction force, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

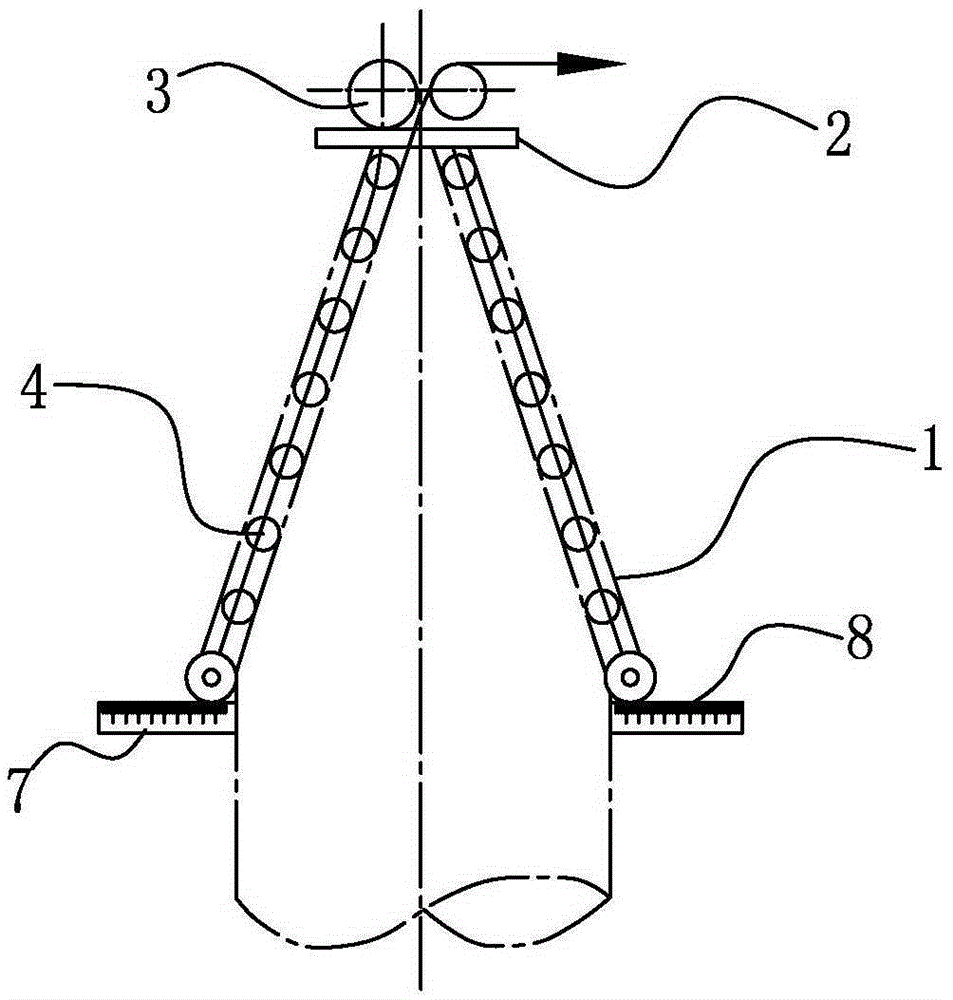

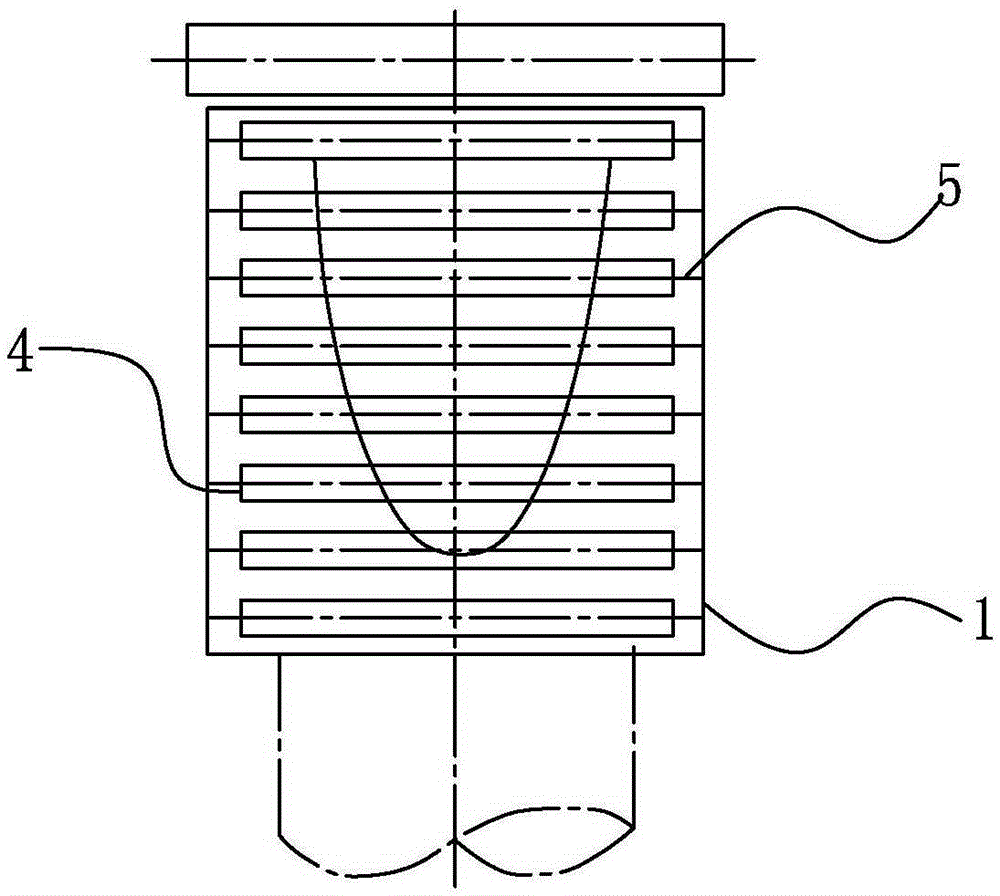

[0018] Example: such as Figure 1-2 Shown: a herringbone splint device for a film blowing machine, including two supporting plates 1 connected at the ends to form a herringbone splint; ; The cross bar 2 is provided with a traction roller 3 for pulling the film; a number of guide rollers 4 for film sliding are embedded in the middle of the support plate 1, and the guide roller 4 passes through the guide roller shaft arranged on the support plate 1 5. Sliding at will; the two ends of the support plate 1 not connected are provided with sliding rollers 6, and the angle of the herringbone plate can be adjusted by sliding the sliding rollers 6.

[0019] The function of the herringbone splint is mainly to guide and stabilize the forward movement of the tubule membrane. The bubble tube film enters the traction roller 3 after passing through the herringbone plate—the circular bubble tube is clamped and flattened into a certain angle in the herringbone plate and then enters the tractio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap