Online wheel set dimension detecting method and device based on two kinds of sensors

A detection method and sensor technology, applied in the field of traffic safety engineering, can solve the problems of high price, high wear and smoothness of wheel treads, and reduced measurement accuracy, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

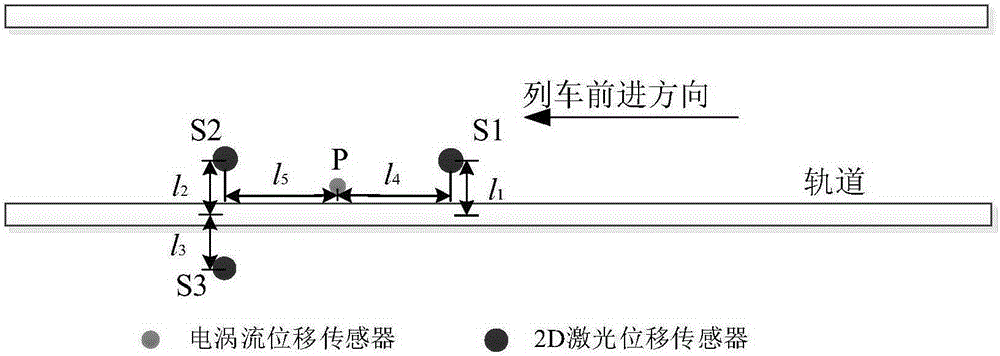

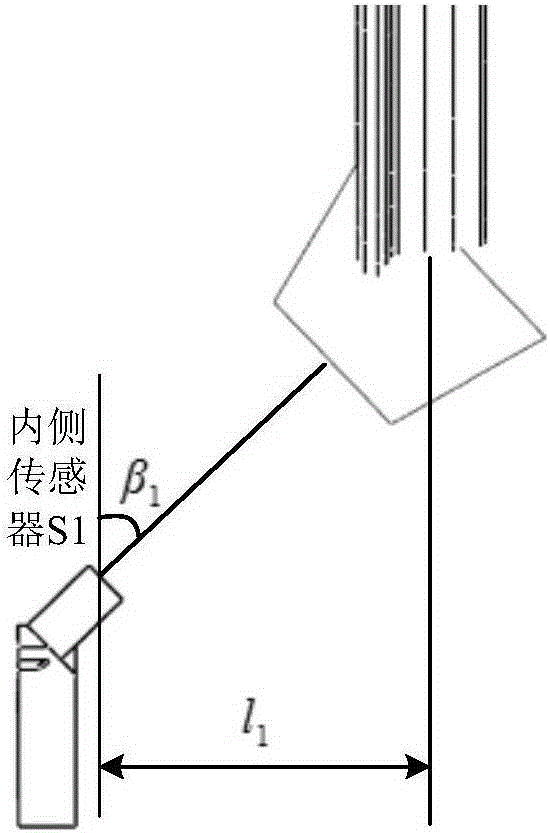

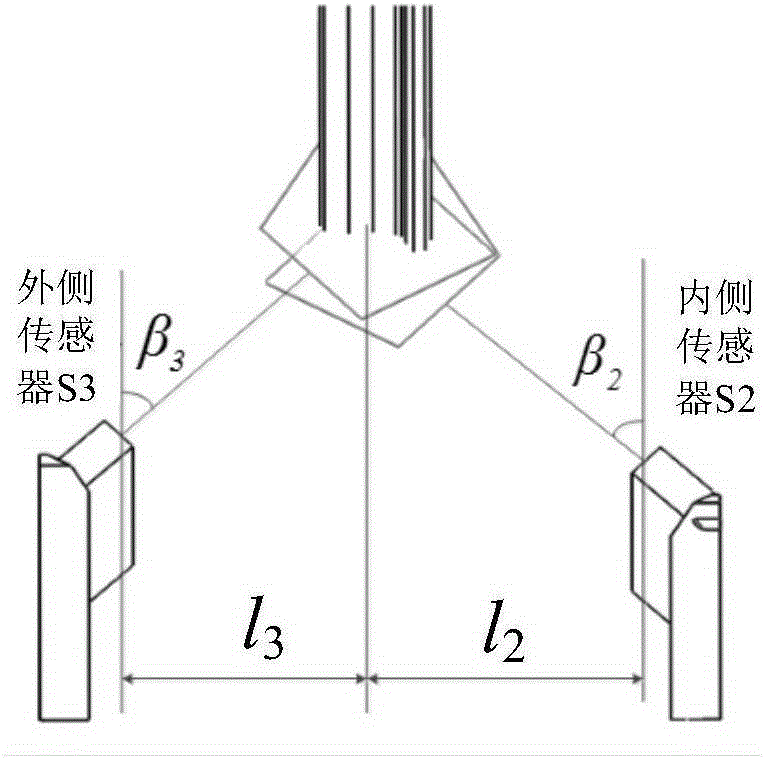

[0060] combine Figure 1-5 , the vertical installation distances between the first laser displacement sensor S1, the second laser displacement sensor S2, and the third laser displacement sensor S3 and the track are all 300mm. The first laser displacement sensor S1, the second laser displacement sensor S2, and the third laser displacement sensor S3 are installed on both sides of the track at an angle of 45° to the vertical line, then β 1 , β 2 , β 3 is 45°; the angle between the first laser displacement sensor S1 and the straight line along the track direction is 46°, the angle between the second laser displacement sensor S2 and the third laser displacement sensor S3 and the straight line along the track direction is 44°, Then α 1 is 46°, α 2 、α 3 Both are 44°. The sampling frequency of the laser displacement sensor and the eddy current displacement sensor is the same, and the sampling interval is 5ms.

[0061] The wheel passes through the detection system, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com