Efficient integrated carton packaging machine

A packaging machine and carton technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of being unable to adapt to the miniaturization of small stores, large area, poor promotion, etc., to achieve compact structure, small area, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

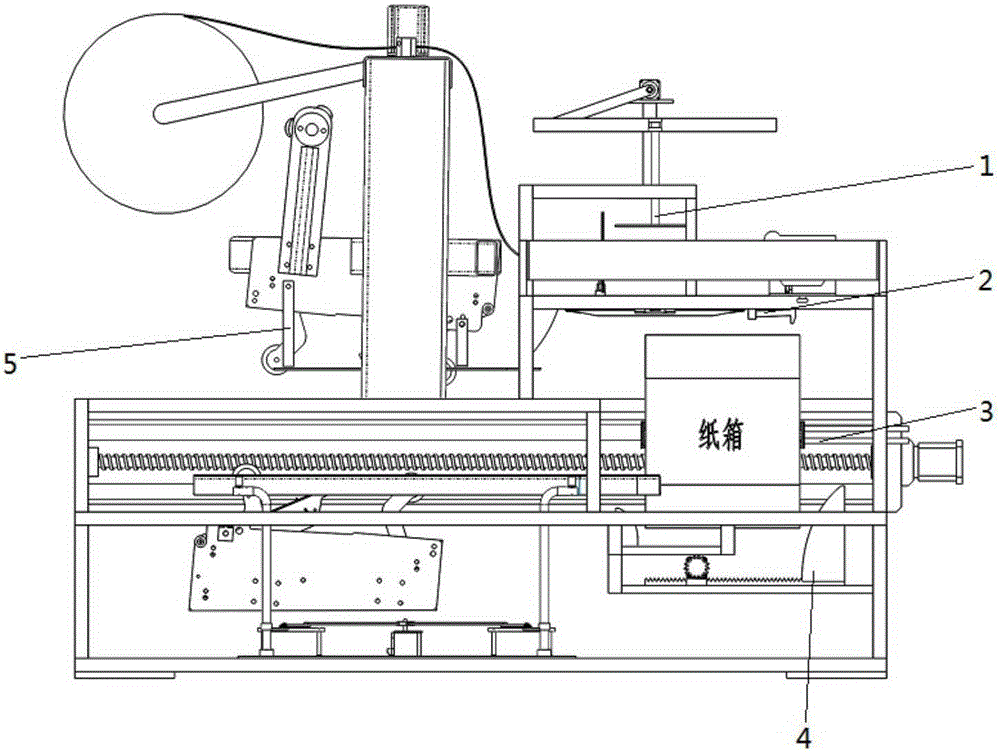

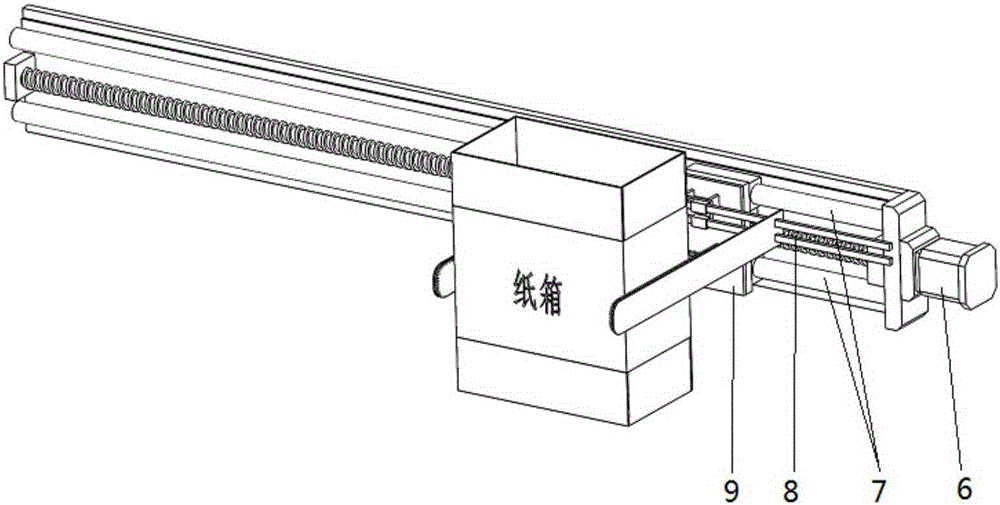

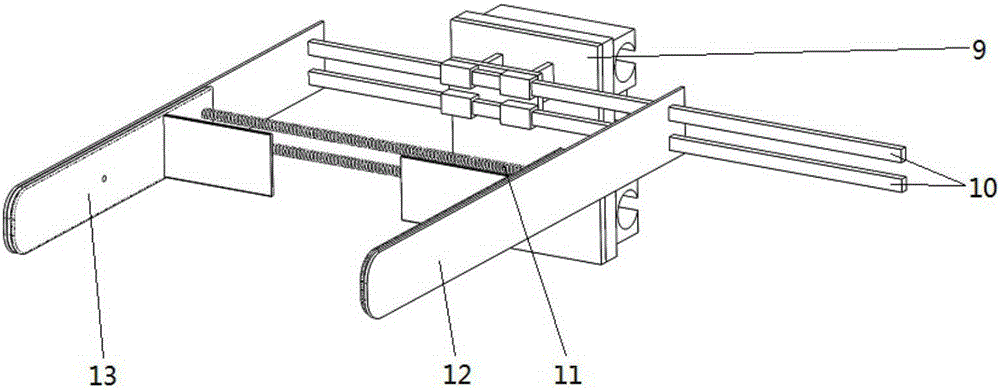

[0024] As shown in Figure 1, this embodiment provides a highly efficient integrated carton packaging machine, which includes a frame on which a carton conveying device 3, an upper bottom closing device 2, a lower bottom closing device 4, Vibration-absorbing packaging device 1, carton sealing device 5, the carton conveying device 3 is arranged along the length direction of the frame, the lower bottom closing device 4 is arranged below the carton conveying device 3, the vibration-damping packaging device 1 It is arranged above the lower bottom closing device 4, and is used to wrap the articles with bubble wrap and put them into the carton after the lower bottom is closed. set up. In the present invention, the carton is clamped and conveyed by the carton conveying device 3, firstly the lower bottom closing device 4 realizes the bottom closing process of the lower bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com