A kind of preparation method of flexible asphalt pavement material

A kind of asphalt pavement and flexible technology, which is applied in the field of preparation of flexible asphalt materials, can solve the problems of low early strength of cold-mix asphalt mixture, insufficient bonding degree, slow water evaporation, etc., achieve fast strength formation, improve bonding performance, Accelerates the effect of early strength development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

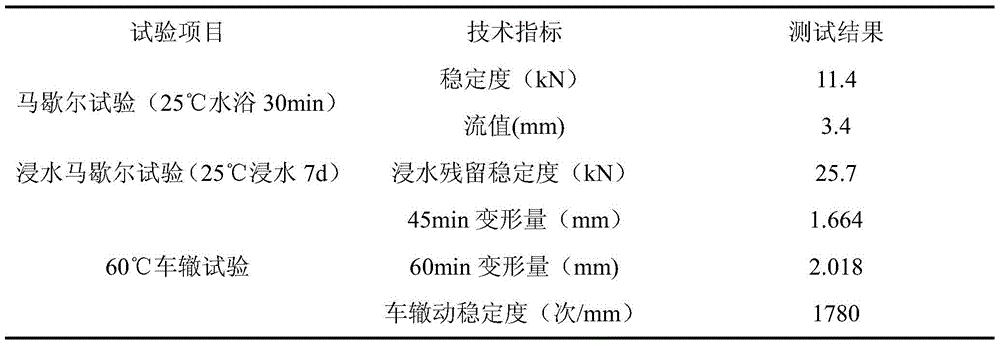

Embodiment 1

[0018] 1. Formula:

[0019] 64.2% of coarse aggregate, 21.3% of fine aggregate, 6.7% of emulsified asphalt, 2.6% of mineral powder, 2.6% of cement, and 2.6% of water; among them, the coarse aggregate is gravel with a particle size greater than 2.36mm, and the fine aggregate is Natural sand with particle size less than 2.36mm. The emulsified asphalt has a solid content of 71% and a standard viscosity of 50 Pa·s.

[0020] 2. Preparation method:

[0021] (1) Put the coarse aggregate and 9 / 13 of the total amount of mineral powder in a mixing pot and mix evenly, then add 4 / 13 of the total amount of water to moisten, then add 19 / 67 of the total amount of emulsified asphalt, and mix evenly Finally, pour it on an iron plate and spread it to a thickness of 1cm, and bake it at 60°C for 30 minutes to complete the first pre-coating of the coarse aggregate;

[0022] (2) Pour the coarse aggregate that has been pre-coated for the first time into the mixing pot, and then add 11 / 67 of the t...

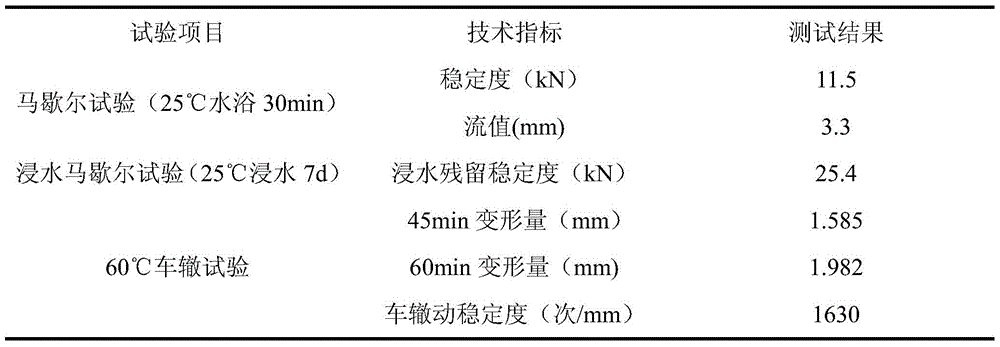

Embodiment 2

[0029] 1. Formula:

[0030] 63.7% of coarse aggregate, 20.9% of fine aggregate, 6.7% of emulsified asphalt, 2.6% of mineral powder, and 3.5% of water; among them, coarse aggregate is crushed gravel with a particle size greater than 2.36 mm, and fine aggregate is crushed gravel with a particle size of less than 2.36 mm mm artificial sand. The emulsified asphalt has a solid content of 71% and a standard viscosity of 50 Pa·s.

[0031] 2. Preparation method:

[0032] (1) Put the coarse aggregate and 9 / 13 of the total amount of ore powder in a mixing pot and mix evenly, then add 8 / 35 of the total amount of water to moisten, then add 16 / 67 of the total amount of emulsified asphalt, and mix evenly Finally, pour it on an iron plate and spread it to a thickness of 1.5cm, and bake it at 60°C for 30 minutes to complete the first pre-coating of the coarse aggregate;

[0033] (2) Pour the coarse aggregate that has been pre-coated for the first time into the mixing pot, then add 11 / 67 of...

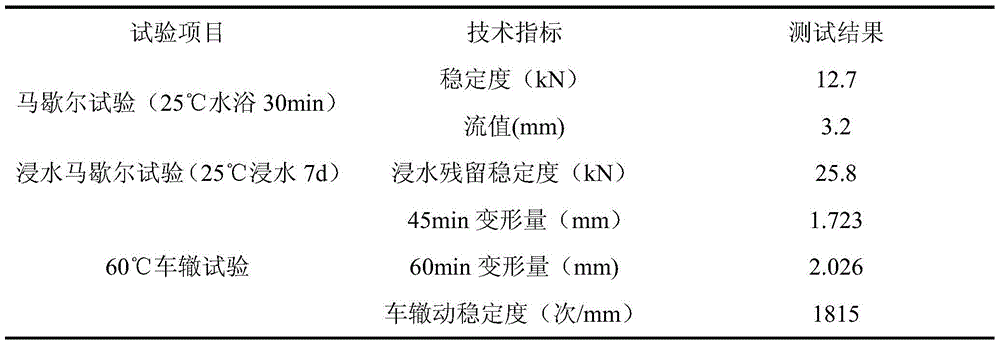

Embodiment 3

[0040] 1. Formula:

[0041] Coarse aggregate is 63.9%, fine aggregate is 21.3%, emulsified asphalt is 7.1%, mineral powder is 2.4%, cement is 2.5%, and water is 2.8%. Among them, coarse aggregate is slag with a particle size greater than 2.36mm, and fine aggregate is granular Stone chips with a diameter less than 2.36mm. The emulsified asphalt has a solid content of 71% and a standard viscosity of 50 Pa·s.

[0042] 2. Preparation method:

[0043] (1) Put the coarse aggregate and 17 / 24 of the total amount of ore powder in a mixing pot and mix evenly, then add 7 / 28 of the total amount of water to moisten, then add 21 / 71 of the total amount of emulsified asphalt, and mix evenly Finally, pour it on an iron plate and spread it to a thickness of 2 cm, and bake it at 60°C for 30 minutes to complete the first pre-coating of the coarse aggregate;

[0044] (2) Pour the coarse aggregate that has been pre-coated for the first time into the mixing pot, and then add 10 / 71 of the total am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com