Method for continuously treating surface of large-area metal material through liquid plasma

A large-area metal, liquid-phase plasma technology is applied in the field of liquid-phase plasma continuous surface treatment of large-area metal materials, which can solve problems such as low cost and low energy consumption, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

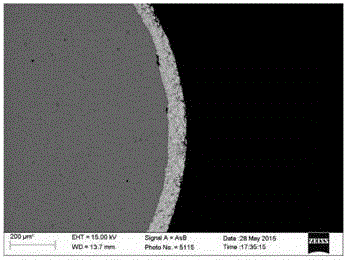

[0031] use figure 1 The mechanical structure shown is to process 2.5mmQ195 low-carbon return steel wire. The size of the insulating microspheres is 0.3mm, and they are placed in a tube made of 800-mesh stainless steel mesh. The length of the tube is 1000mm. Plastic seal, low-carbon steel wire is inserted from the center of the plastic seal, and can move in one direction under the drag of the transmission device, the moving speed can reach 50mm / s, the solution is 10% sodium bicarbonate solution, and the solution is controlled by temperature The system is heated to 80 degrees Celsius and enters the reaction tank. The applied voltage is 180V, the frequency is 4000Hz, and the duty cycle is 80%. The average processing time of the whole line is 20s, which can completely remove the oil and scale on the surface. The arithmetic mean roughness of the surface was 1.5 micrometers.

Embodiment 2

[0033] use as figure 1 The mechanical structure shown is to clean the 8mm Q335 light round steel bars. The size of the insulating microspheres is 0.5mm, and they are placed in a tube made of 500 mesh steel mesh. The cathode is connected, and it is placed in the center of the barrier layer. The outermost end of the reaction tank is equipped with an anode made of graphite tube, which is connected to the positive electrode of the power supply. It is a 7% sodium carbonate solution, the liquid flows into the reaction tank at a rate of 30L / min, directly injects into the barrier layer, and flows back from the channels on both sides of the reaction tank. The temperature of the liquid is controlled between 75-80 degrees Celsius, and the negative and anode are loaded The voltage is 200V, the frequency is 6000Hz, and the duty cycle is 50%. After 30 seconds of treatment, the surface changes from black to discolored, without metallic luster, relatively rough, and completely free of scale. ...

Embodiment 3

[0035] use as figure 1The mechanical structure shown is to clean the No. 45 warm-rolled steel plate with a width of 100 mm and a thickness of 2 mm. The size of the insulating microspheres is 0.5 mm, and they are placed in a cavity made of a 500-mesh steel mesh. The width of the cavity is 150 mm. The upper and lower heights are 20mm. Place the steel plate in the center of the cavity filled with insulating microspheres along the long axis, and connect it to the negative electrode of the pulse power supply through a conductive device. The entire reaction area enters the solution. The outermost end of the reaction tank is equipped with a large graphite plate. The anode of the battery is connected to the positive pole of the power supply. The length of the arc reaction zone is 100mm, the speed of the steel plate passing through the reaction zone is 5mm / s, the solution used is 10% sodium carbonate solution, the liquid flows into the reaction tank at a rate of 60L / min, and the inflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com