Roadbed concrete bed structure and construction method

A technology of concrete and concrete layer, applied in the directions of roads, roads, buildings, etc., can solve the problems of difficulty in water-stopping, unable to control the linear shape of water-stopping belt, destroying the integrity of the end of the concrete foundation bed, etc., so as to avoid the overall Sexual damage, the effect of controllable installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

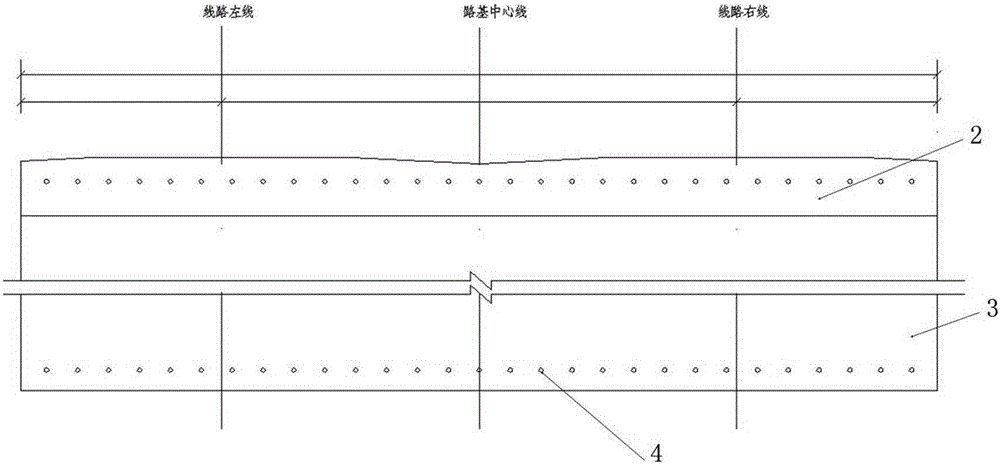

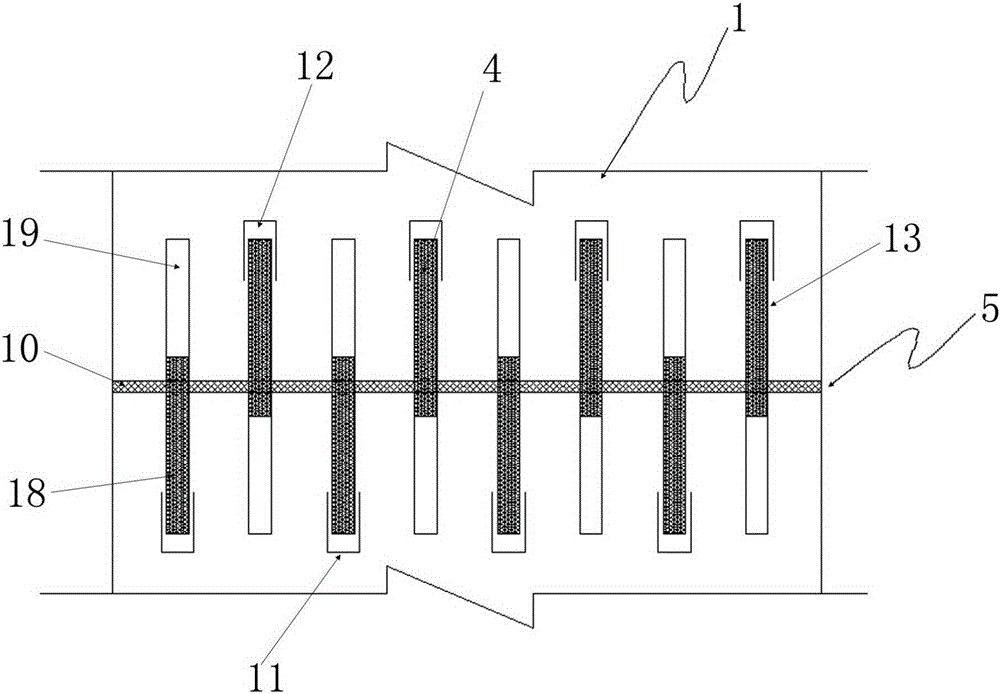

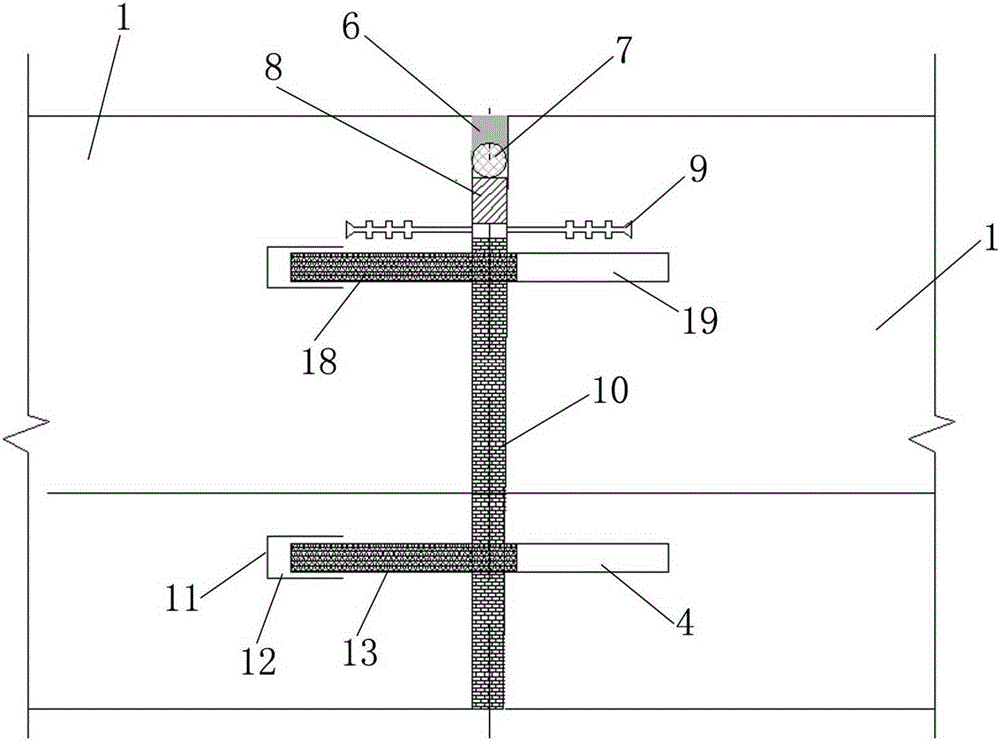

[0031] Such as Figure 1-4 A roadbed concrete subgrade structure is shown, which has several sections of concrete subbed 1 and ballastless tracks arranged on several sections of concrete subbed 1, and each section of concrete subbed is divided into C35 concrete layer 2 from top to bottom , C20 concrete layer 3, graded crushed stone layer mixed with 5% cement, and filler layer; ballastless track is laid on the concrete subbed 1 through several sections of base plates, and there are expansion joints 5 between adjacent concrete subbeds 1, so The above-mentioned expansion joints 5 match the gaps between adjacent base plates, and each section of concrete foundation bed 1 is aligned with the corresponding base plates. Among them, the thickness of C35 concrete layer 2 is 0.5m, and the thickness of C20 concrete layer 3 is 0.5m. Preferably, the width of the expansion joint 5 is 20mm, such as image 3 The shown expansion joint 5 is provided with a polyurethane sealant 6, a backing mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com