Heavy type wood frame self-resetting node

A wood frame, self-resetting technology, applied in building components, earthquake resistance, construction, etc., can solve the problems of economic loss, building performance discount, prestress loss, etc., to achieve the effect of convenient maintenance and avoid structural overhaul.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

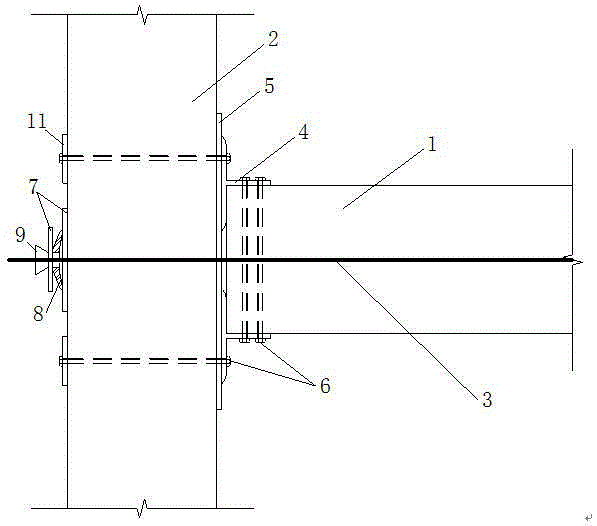

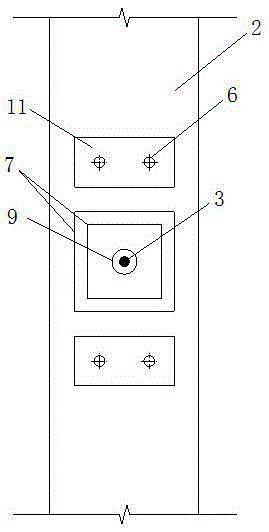

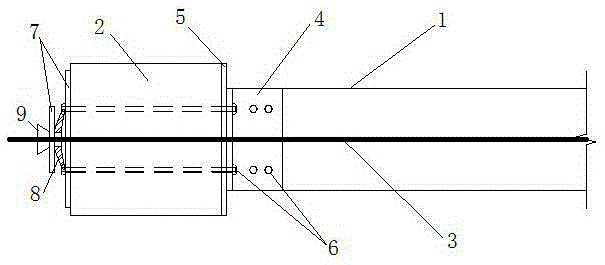

[0030] like figure 1 , 2 As shown in and 3, it is a self-resetting joint of a beam-column of a heavy-duty wooden frame, including a wooden beam 1, a wooden column 2, a prestressed tendon 3, a beam end energy-dissipating steel 4, a wooden column reinforced steel plate 5, and a bolt 6. The beam 1 and the wooden column 2 are connected by bolts 6 through the energy-dissipating section steel at the end of the beam. The prestressed tendon runs through the wooden beam 1 longitudinally along the wooden beam, and runs through the wooden column 2 along the horizontal direction of the wooden column. The column 2 is away from the back of the wooden beam 1, and is anchored by the anchor pad 7, the disc spring 8 and the anchor 9.

[0031] The cross-sectional shape of the wooden beam 1 and the wooden column 2 can be rectangular or square.

[0032] The wooden beam 1 and the wooden column 2 are made of log, sawn timber, glulam, laminated veneer lumber, parallel wood veneer or laminated wood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com