Wind driven generator and wind generating set

A technology of wind power generators and wind power generators, which is applied in the direction of wind power motor combination, wind power engine, wind power generation, etc. It can solve the problems of uneven air gap and other problems, and achieve the prevention of air gap change, the reduction of axial distance, and the relative displacement Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

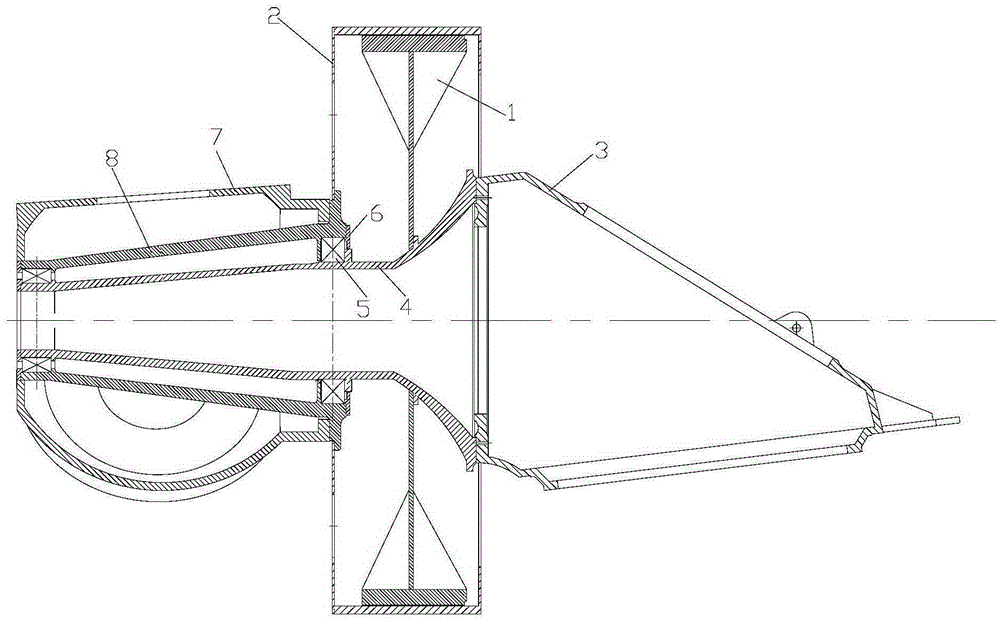

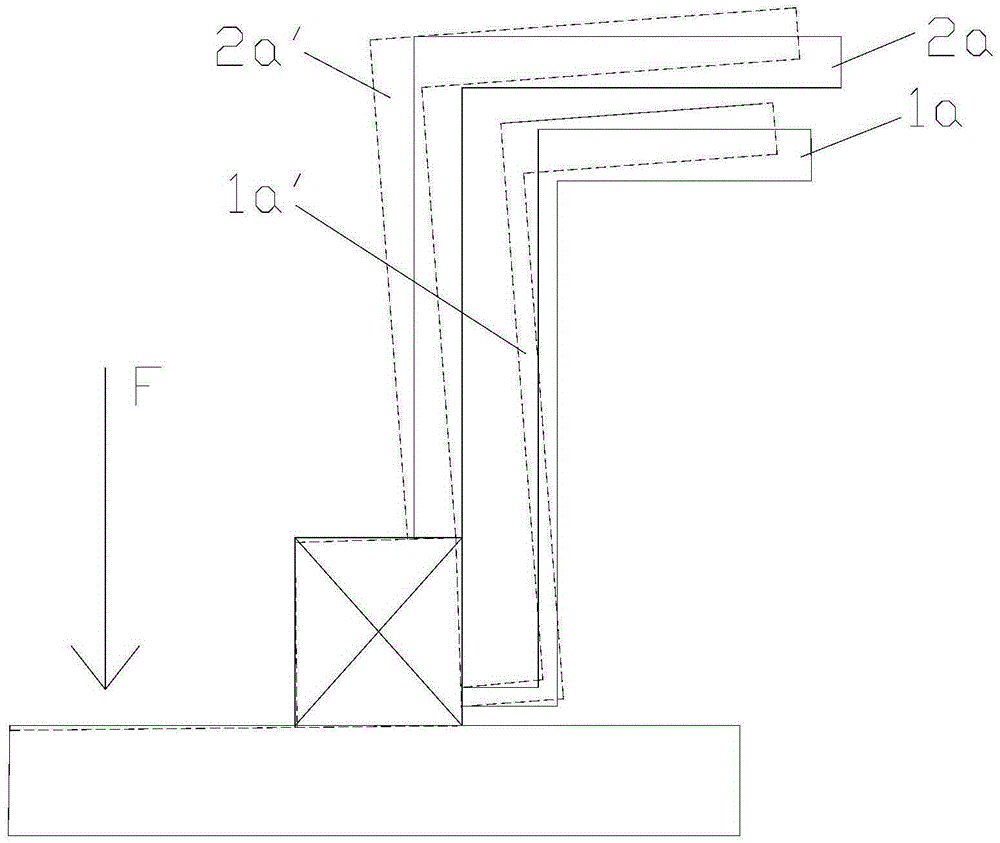

[0031] Such as Figure 2 to Figure 4 As shown, in this embodiment, the wind power generator includes a fixed shaft 10 , a moving shaft 20 , a bearing assembly, a stator 40 and a rotor 50 . The fixed shaft 10 is used to carry other components. The moving shaft 20 is sleeved on the fixed shaft 10 through a bearing assembly, and can rotate relative to the fixed shaft 10 . The bearing assembly includes a first bearing 31 , the inner ring of the first bearing 31 is fixedly arranged on the fixed shaft 10 , and the outer ring of the first bearing 31 is fixedly connected with the moving shaft 20 , so that the moving shaft 20 can rotate relative to the fixed shaft 10 . The stator 40 is fixedly connected to the inner ring of the first bearing 31 . The rotor 50 is fixedly connected to the moving shaft 20 , and the position of the rotor 50 on the moving shaft 20 corresponds to the first bearing 31 along the radial direction.

[0032] Since the stator 40 is fixed on the inner ring of th...

Embodiment 2

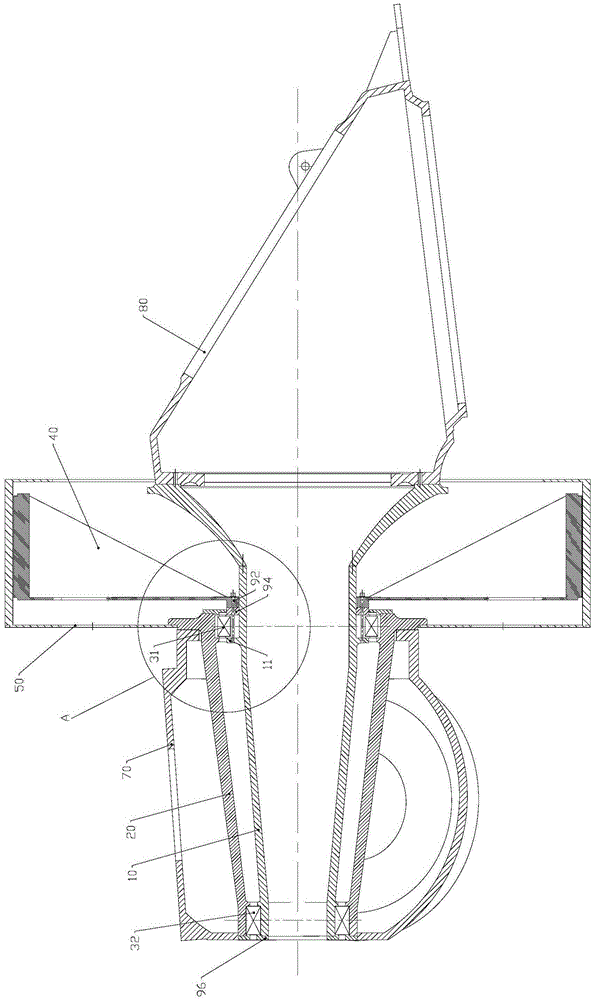

[0047] Such as Figure 5 and 6 As shown, in this embodiment, except for the arrangement positions of the fixed shaft flange 11 and the sealing ring 94, the structure and arrangement positions of other components are the same as those in the first embodiment.

[0048] In this embodiment, the fixed shaft flange 11 is located between the first bearing 31 and the stator 40 . The fastening bolts 92 pass through the threaded holes on the stator 40 , the fixed shaft flange 11 and the inner ring of the first bearing 31 in sequence. The fastening bolt 92 is clearance fit with the hole on the fixed shaft flange 11 and the hole on the stator 40 .

[0049] The sealing ring 94 is sleeved on the peripheral surface of the fixed shaft flange 11, and seals the gap 91 between the peripheral surface of the fixed shaft flange 11 and the bearing cover 93 (see Figure 4 ),Such as Figure 5 As shown, the bearing cover 93 is fixedly connected to the end of the moving shaft 20 close to the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com