Buckle assembly

A buckle and female buckle technology, applied in the direction of quick-action fasteners, etc., can solve the problems of loose connection between the female buckle and the female buckle, small thickness range of the buckle, poor installation and disassembly, etc., so that it is not easy to loosen and convenient for employees Operation, performance and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

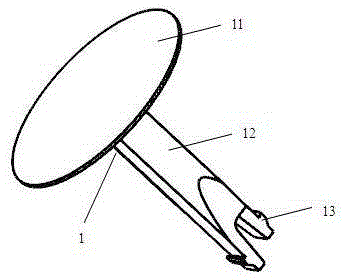

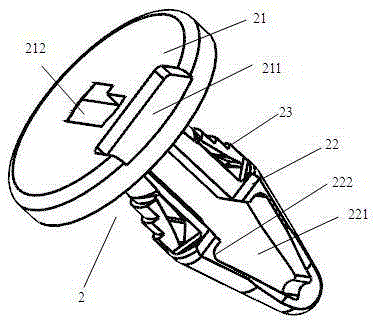

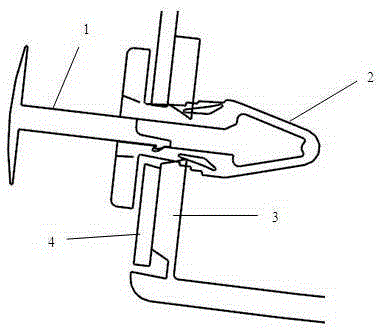

[0021] Such as Figure 1-2 As shown, the buckle fitting of the present invention includes a sub-button 1 and a female buckle 2 that can be snapped together. The sub-button 1 includes a pressing part 11, a guide post 12 and a limiting structure 13. The insertion end of the guide post 12, the pressing part 11 is located at the other end of the guide post 12, and the female button 2 includes a female button base 21, a guide part 22 and a step on the side of the guide part 22 The engaging part 23, the guide part 22 is provided on the female button base 21, the female button base 21 is provided with a through hole 212 for inserting the child button 1, and the guide part 22 is provided with a hollow part 221 , the through hole 212 corresponds to the hollow portion 221 , and the sub-buckle 1 is snapped into the hollow portion 221 .

[0022] With th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com