High-pressure pollution discharge pneumatic valve

A pneumatic valve, high pressure technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem that the valve core cannot be opened according to the design, reduce the exhaust pressure and final volume flow, and the valve core cannot be completely sealed, etc. To achieve the effect of easy guiding and positioning, reducing the possibility of dislocation, and avoiding the pressing force of the valve core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

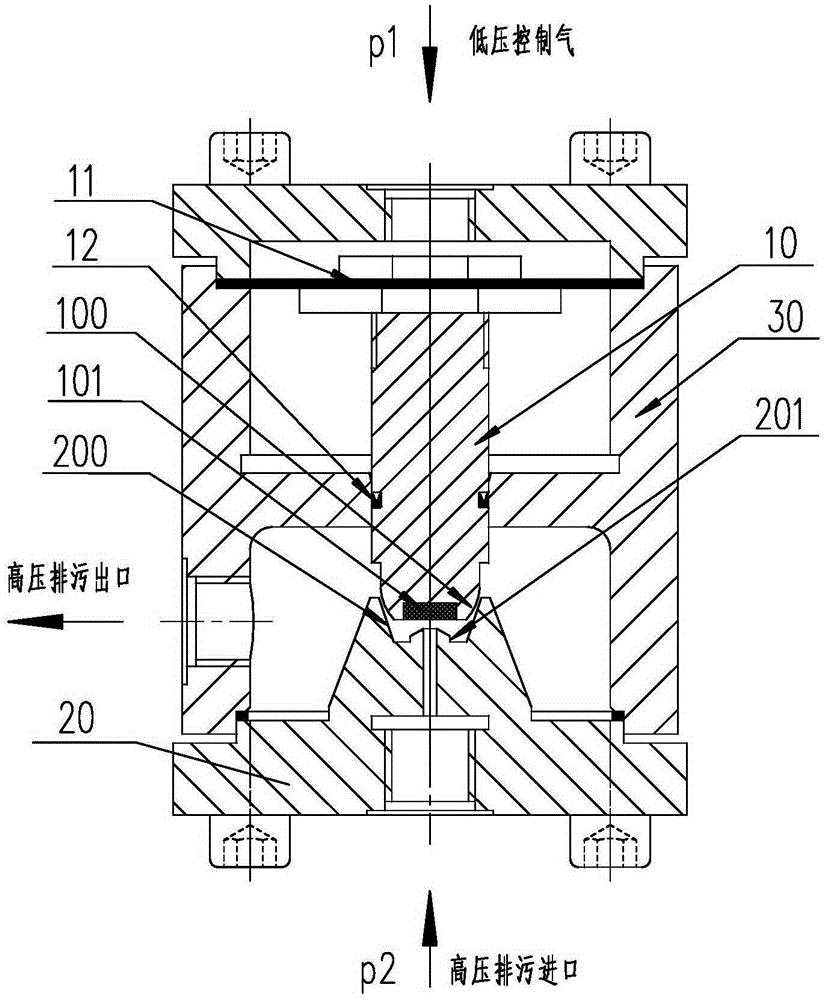

[0034] Such as figure 2 As shown, the outer edge of the sealing surface at the lower end of the valve core 10 is set as a valve core spherical surface 100, and the valve seat sealing position forms a tangential primary seal through the valve seat inclined guide surface 200 and the valve core spherical surface 100; The middle part of the sealing surface at the lower end of the valve core 10 is set as a polytetrafluoroethylene valve core filling block 101, and the valve seat sealing part is formed by the valve seat protrusion block 201 and the valve core filling block 101 to form a pneumatic valve along the valve core 10. Secondary sealing in the stroke direction, the valve core filling block 101 during the secondary sealing is blocked at the high-pressure sewage inlet of the pneumatic valve located on the valve seat raised block 201; that is, the sealing surface at the lower end of the valve core 10 is set It is a joint structure of the valve core spherical surface 100 and the...

Embodiment 2

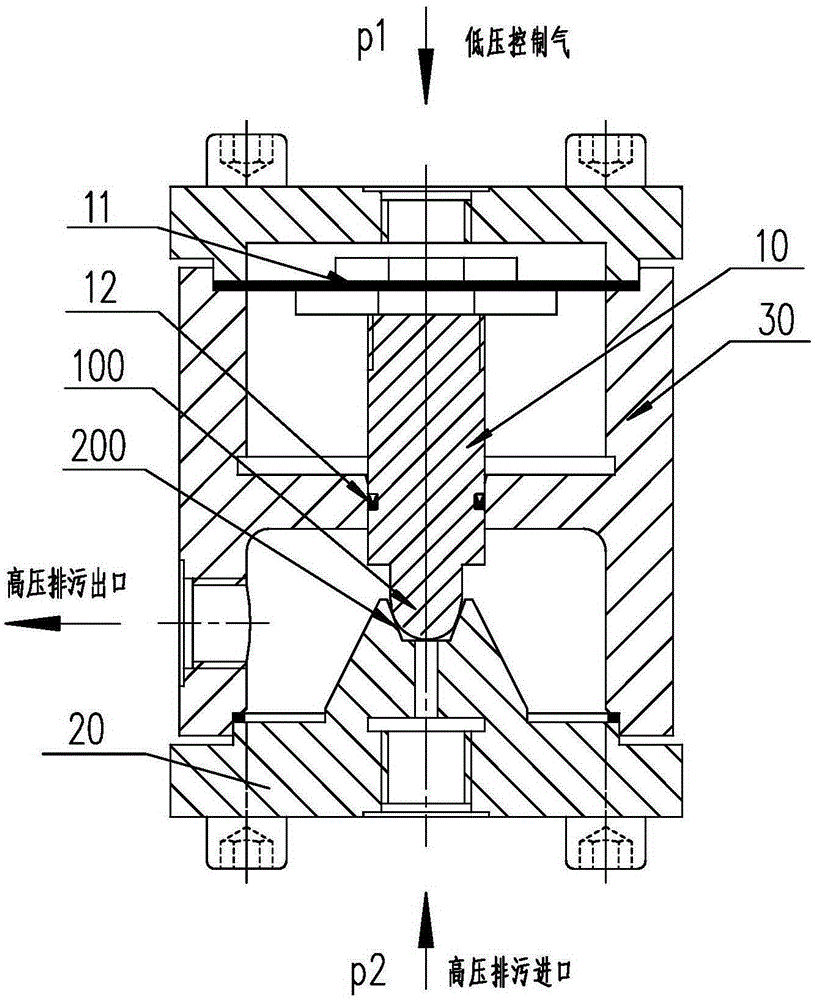

[0036] Such as image 3 As shown, the sealing surface at the lower end of the valve core 10 is set as a valve core spherical surface 100 as a whole, and the valve seat sealing part forms a tangential primary seal through the valve seat inclined guide surface 200 and the valve core spherical surface 100; The sealing part of the seat cooperates with the tangential contact of the spherical top surface of the valve core to form a secondary seal along the stroke direction of the valve core 10 .

[0037] In the above embodiment, the size of the inner cavity surrounded by the inclined guide surface 200 of the valve seat is larger than the spherical surface 100 of the valve core, so that the inclined guide surface 200 of the valve seat can completely accommodate the sealing surface of the lower end of the valve core 10 .

Embodiment 3

[0039] Such as Figure 4 , 5 As shown, the structure in embodiment 3 is relatively close to the structure in embodiment 2, the difference is that the head of the sealing surface at the lower end of the valve core 10 in embodiment 3 is set in a convex shape, and the convex head is set as It is just inserted in the high-pressure sewage inlet of the pneumatic valve, thereby improving the sealing effect compared with the structure in Embodiment 2.

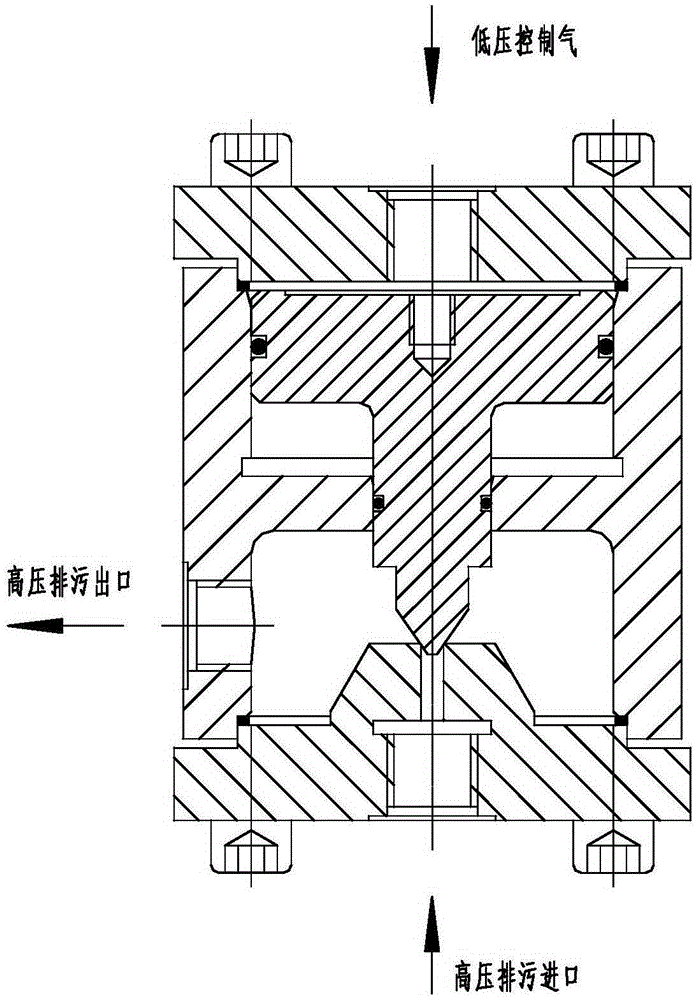

[0040] The working principle of the pneumatic valve of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041]The high-pressure gas p2 enters from the bottom of the pneumatic valve and acts on the lower part of the valve core 10; the low-pressure control gas p1 enters from the top of the pneumatic valve and acts on the top of the valve core 10. During the air delivery process of the compressor, the action of p2 and p1 makes the valve core 10 and the valve seat 20 in a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com