Pipeline internal inspection robot

A technology of robots and pipelines, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of different force on the base, forward or backward tilt, and affecting the continuous operation of the crawler, so as to ensure normal operation. Running, avoiding the effect of excessive force gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

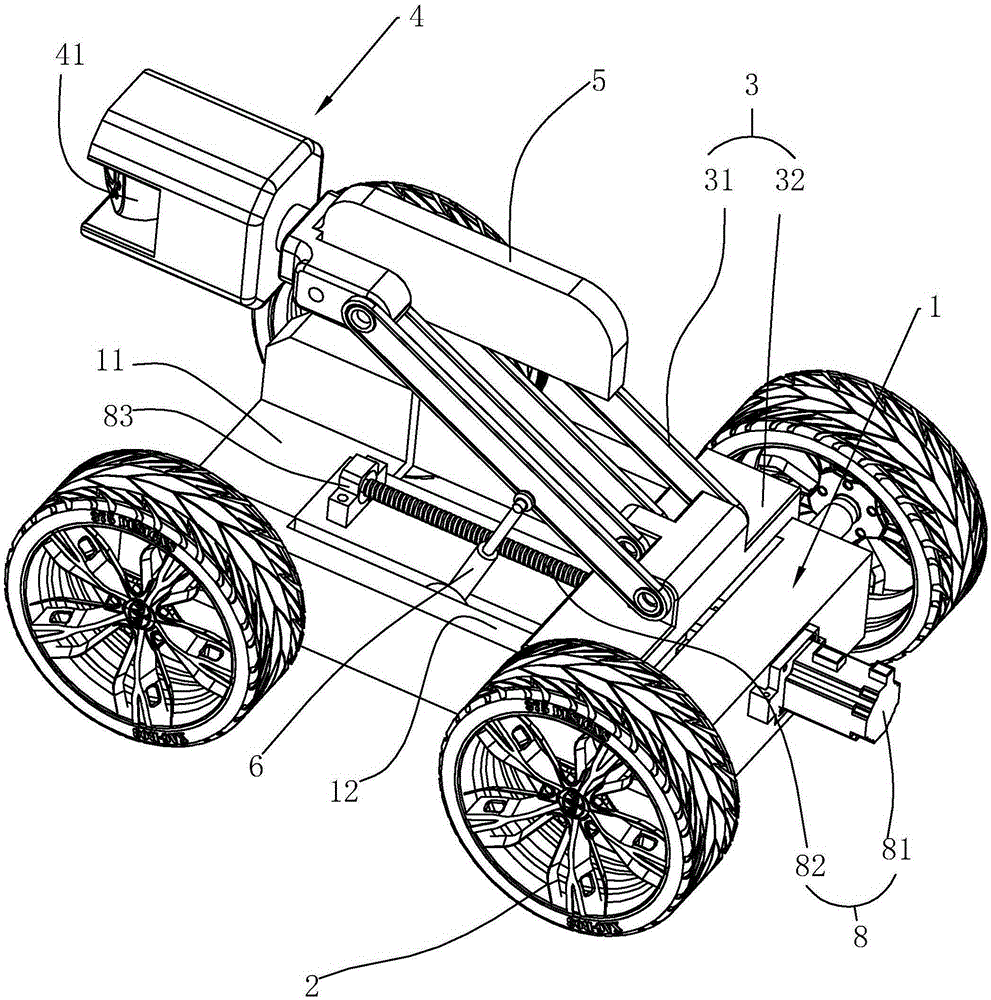

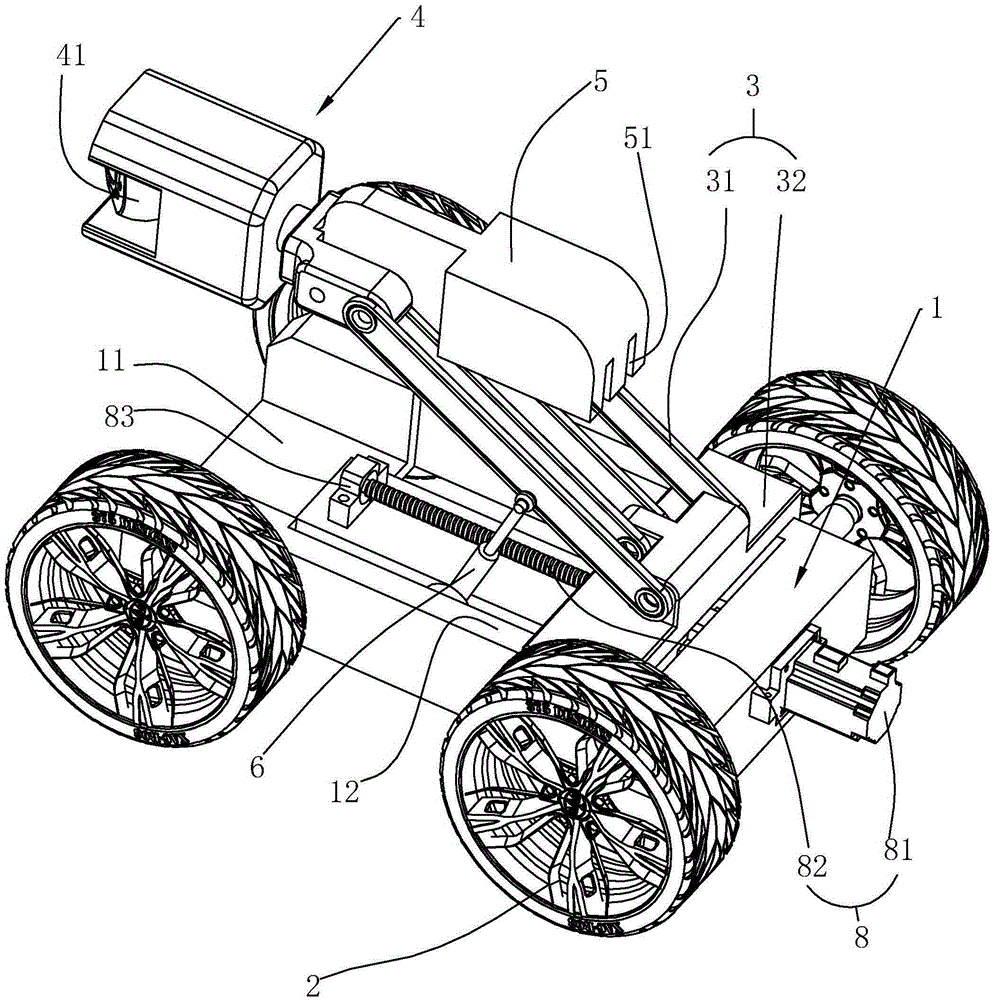

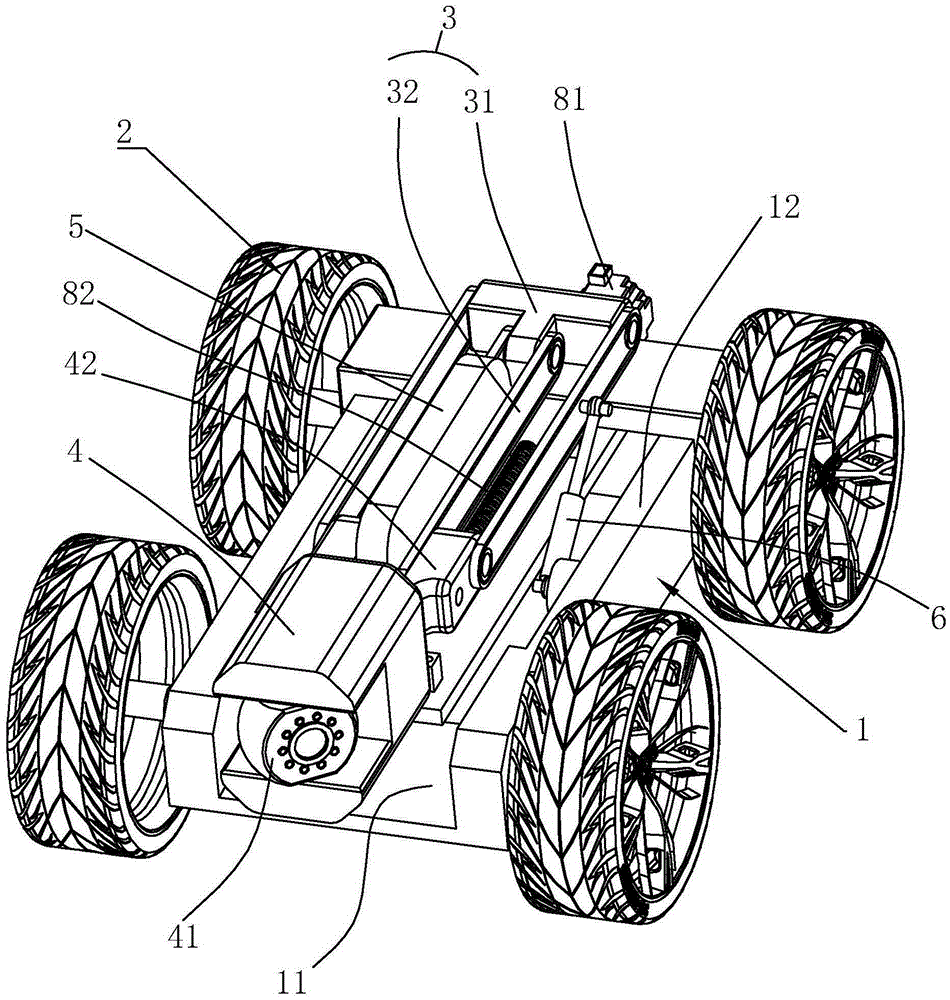

[0023] The inspection process of the pipeline endoscopic robot is as follows: the inspector remotely controls the speed and direction of the pipeline endoscopic robot in the pipeline through the controller; adjusts the rotation and zoom of the camera 41 to achieve clear imaging in different directions; controls the height of the lifting frame 3 to Adapt to the detection of different pipe diameters. With the assistance of lighting, the internal situation of the pipeline is presented on the monitor screen through the video and display system, and the video data is stored, and the detection distance is determined by the length calculator.

[0024] Such as figure 1 What is shown is the state when the lifting frame 3 raises the camera assembly 4. There are two ways for the pipeline endoscopic robot to advance, one is the traditional rubber wheel type; the other is the crawler type. Both are driven by motors. The two motors control the rotation direction of the wheels on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com