Device for exposed radiographic testing of circumferential weld joint of annular workpiece

A circumferential weld seam and radiographic inspection technology, applied in the field of workpiece weld seam inspection, can solve the problems of undetectable harmful defects, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure and use of the device for detecting the radiation exposure of the circular workpiece circumferential weld seam according to the present invention will be further described through the examples below.

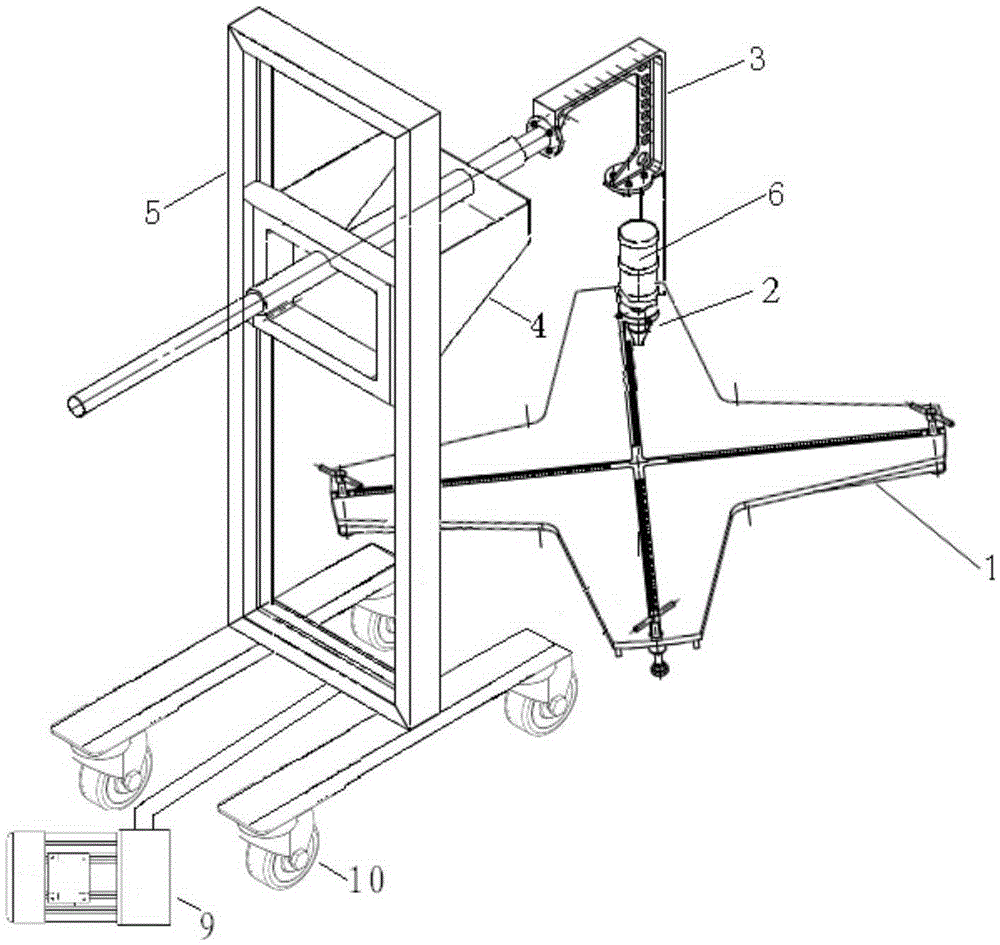

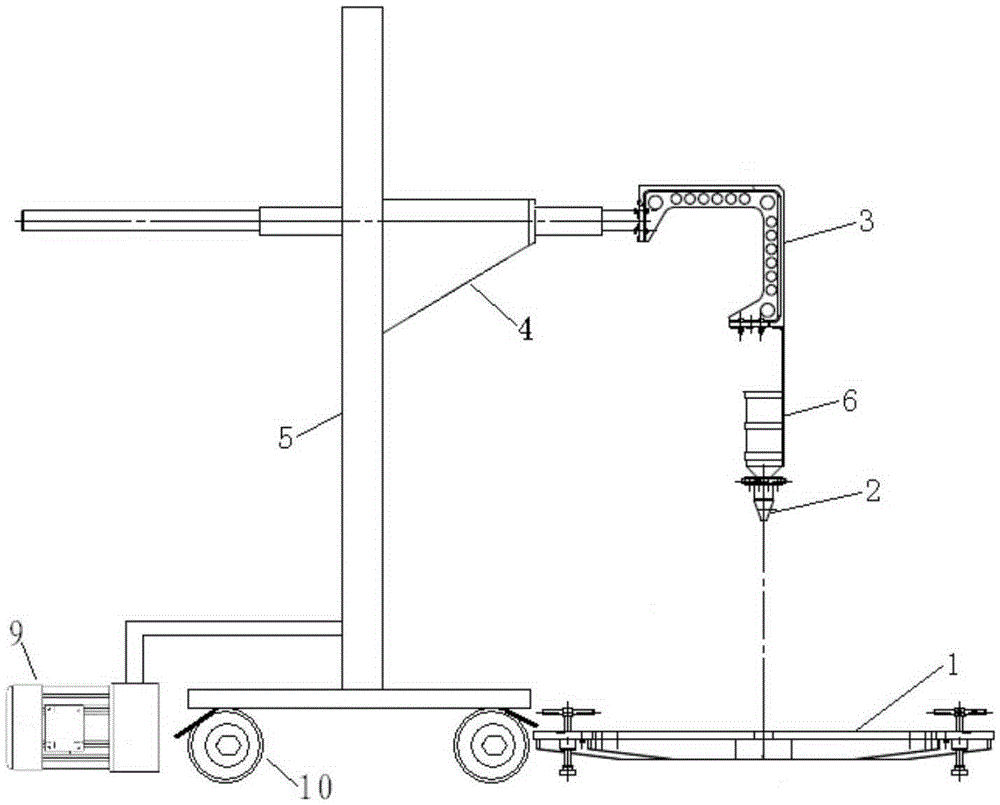

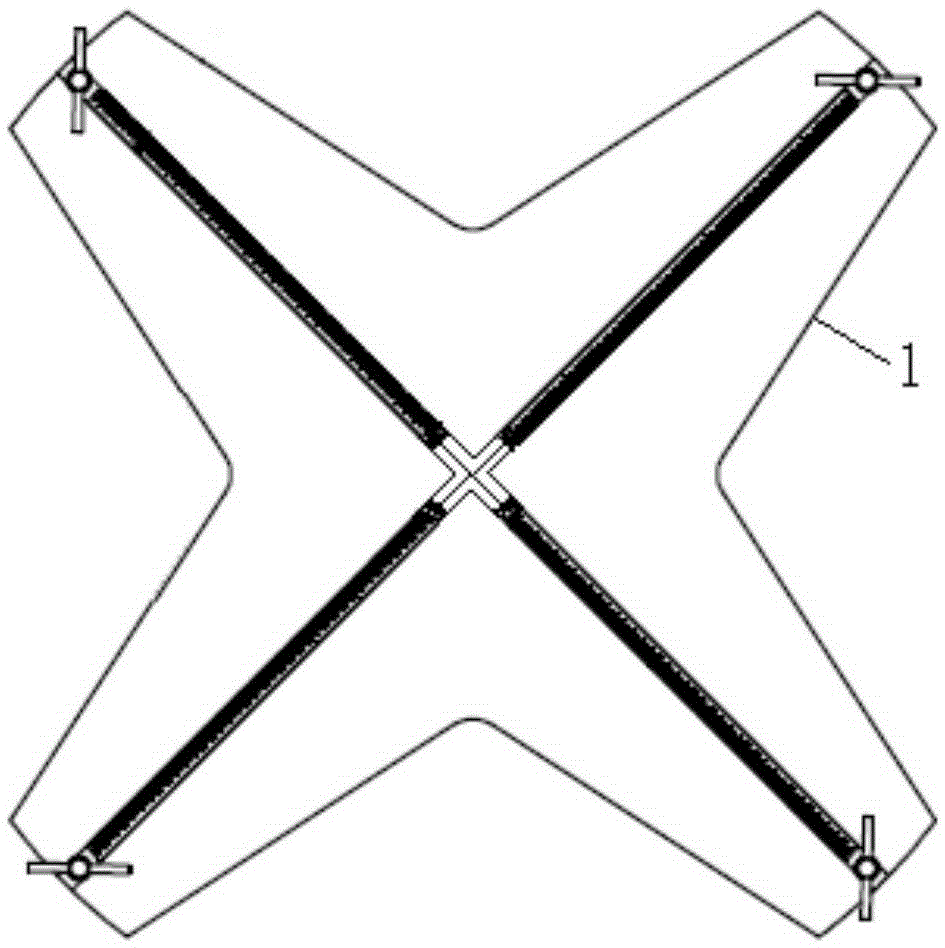

[0024] The device for the exposure radiation detection of the circular workpiece circumferential weld seam described in this embodiment has the following structure: Figures 1 to 6 As shown, the composition includes a device frame, an X-ray emission alignment device installed on the device frame, and a workpiece placement table 1. The composition of the device frame includes a portal frame 5 fixed on the base frame, and a pair of guide rails. The lifting frame installed on the portal frame 4, the motor transmission mechanism that drives the lifting frame to move up and down 9, the handle mechanism that drives the lifting frame to move up and down for fine adjustment, the supporting beam installed on the lifting frame, and the upper end installed on the hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com