Method using dilatometer to measure electronic flat glass shrinkage

A technology of flat glass and test method, applied in the direction of thermal expansion coefficient of materials, etc., can solve the problems of power failure of electronic display, large error of test results, affecting the quality of electronic products, etc., achieve uniform heating, accurate calculation of shrinkage value, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment:

[0019] A method utilizing a dilatometer to test shrinkage of electronic flat glass, said test method comprising the steps of:

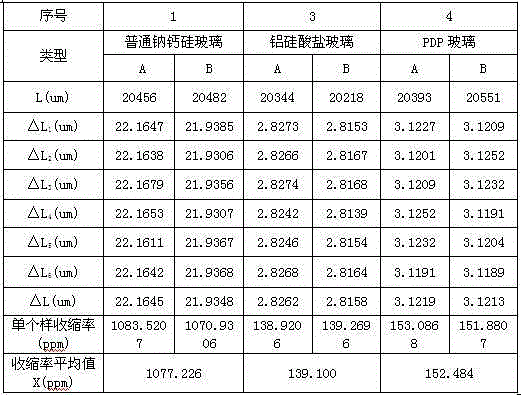

[0020] 1) Take a piece of electronic flat glass to be tested, divide the sample to be tested into two pieces A and B along the length direction, and grind the two ends of the electronic flat glass A and B in the length direction, and the flatness is A and L B , and convert the length unit to μm, and the decimal is accurate to one digit;

[0021] 2) Enter the sample name at the "Name" of the "General settings" interface on the dilatometer, and input the sample length L at the "Length" A , and set the heating curve system on the "Temperature profile" interface: heat up at a heating rate of 5°C / min, the temperature rises to 580°C, and then keep at this temperature for 5 minutes to make the glass evenly heated, and finally set the temperature at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com