Multi-view pointer type instrument identification method and device

A recognition method and multi-view technology, which is applied in the field of multi-view pointer instrument recognition, can solve problems such as unrecognition, and achieve the effects of improving automation, strong robustness, and simplifying manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

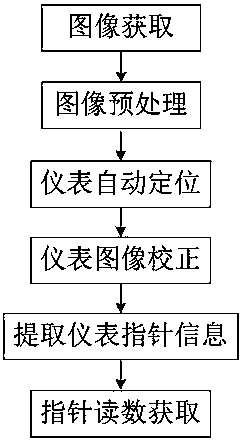

[0016] Such as figure 1 As shown, the present invention has five main implementation steps, namely image acquisition and data modeling, instrument automatic positioning, instrument image correction, instrument pointer automatic extraction and instrument reading calculation, the specific implementation of each part is as follows:

[0017] 1. Image acquisition and data modeling

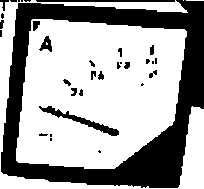

[0018] Such as figure 2 As shown, the camera is used to obtain a high-definition image containing instrument information. There is no positional rotation between the camera and the instrument. First, the instrument image I is manually cropped to record each display scale value S and the corresponding angle value A. According to these information Fit the instrument pointer scale model S=F(A), which is used to calculate the final scale value of the instrument. For the case where the scale of the pointer meter is displayed uniformly or non-uniformly, the relationship between S and the corresponding A sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com