Spin type large rotary spray dust suppression spray rack

A spray dust reduction and spin-type technology, which is applied in the field of coal mine equipment, can solve the problems of high maintenance cost, high use cost, and influence on the dust removal effect, and achieve the effects of flexible installation methods, strong wind resistance, and strong structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

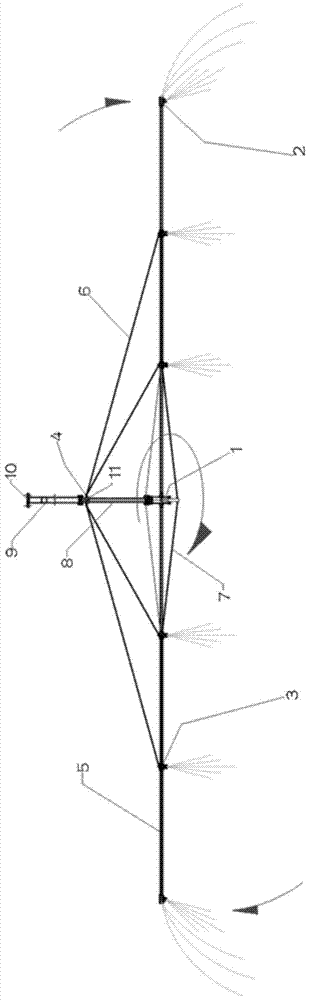

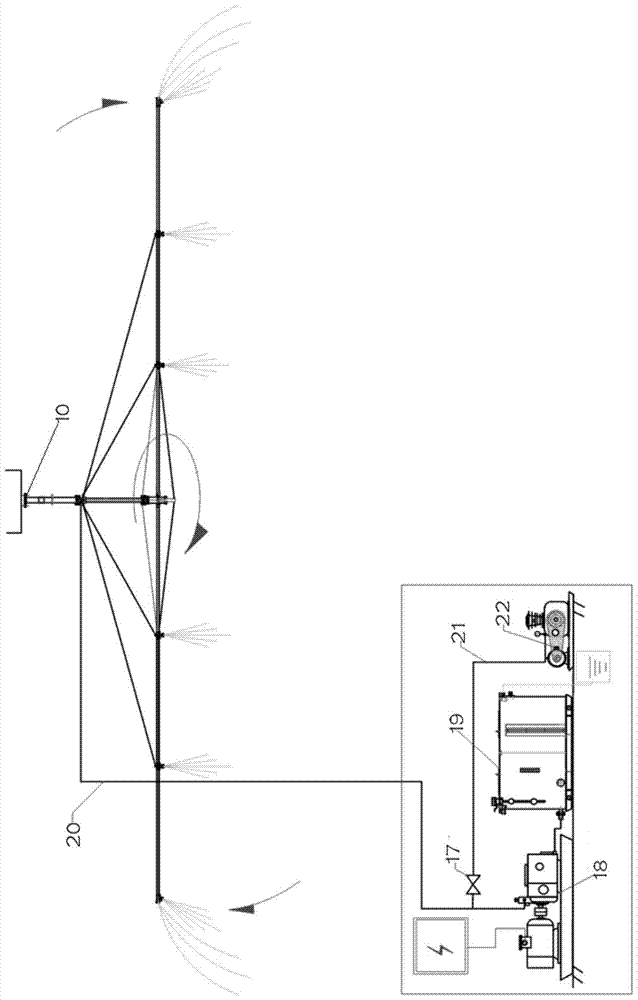

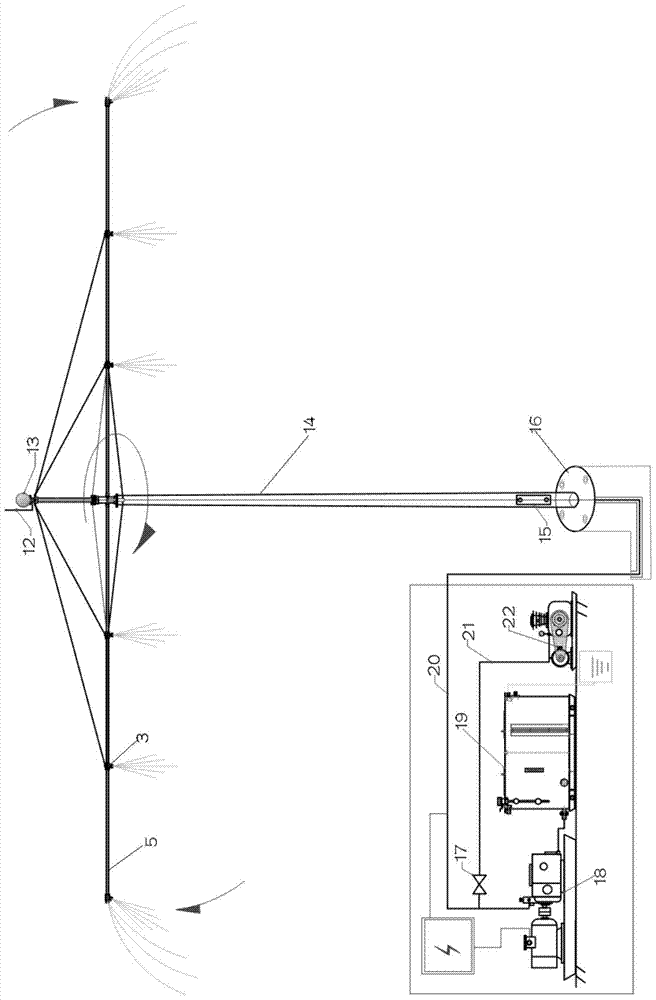

[0037] In order to meet the requirements of dust removal and spraying in various environments such as airtight and open, the present invention proposes a spin-type large-rotation spray and dust reduction spray rack, which rotates by itself based on the principle of air reverse thrust.

[0038] Such as figure 1 As shown, a spin-type large-rotation spray dust suppression spray rack includes a shaft tube 8, and one end of the shaft tube 8 is perpendicular to the shaft tube 8. A support tube 5 that can rotate at the end of the shaft tube 8 is installed. The support tube 5 is relatively The shaft tube 8 is arranged symmetrically, and a plurality of spray heads 23 are distributed on the support tube 5 , wherein the spray heads 23 at both ends of the support tube 5 face opposite directions.

[0039] The basic structure constituting the spray rack is the shaft tube 8 and the support tube 5, wherein the shaft tube 8 is used for installation and fixing, and the support tube 5 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com