Blueberry screening machine having cleaning function

A screening machine and blueberry technology, applied in solid separation, grading, food processing, etc., can solve the problems of increased workload, time-consuming and laborious picking and screening, and inaccurate manual screening, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

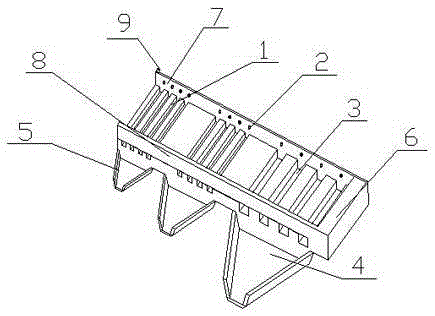

[0013] Attached below figure 1 The present invention is further described in detail with specific embodiments.

[0014] A blueberry screening machine with a cleaning function, comprising a screening plate 1 and a receiving tray 4. The screening plate 1 is arranged obliquely, and the screening plate 1 is provided with several inclined grooves 3 horizontally. The first baffle plate 7 and the second baffle plate 8 are vertically arranged, the middle part of the first baffle plate 7 is provided with a water storage chamber, and the inner wall of the first baffle plate 7 is uniformly provided with a plurality of water outlet holes 2, and each water outlet hole 2 corresponds to 3 for each groove. The top of the first baffle plate 7 and the high-end position near the first baffle plate 7 are provided with a water inlet 9, and the water inlet 9 and the water outlet hole 5 are respectively communicated with the water storage chamber; the receiving tray 4 is provided with a feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com