Polishing slurry filtering device

A filtering device and polishing liquid technology, applied in the field of electrochemical polishing, can solve problems such as poor consistency of silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and drawings.

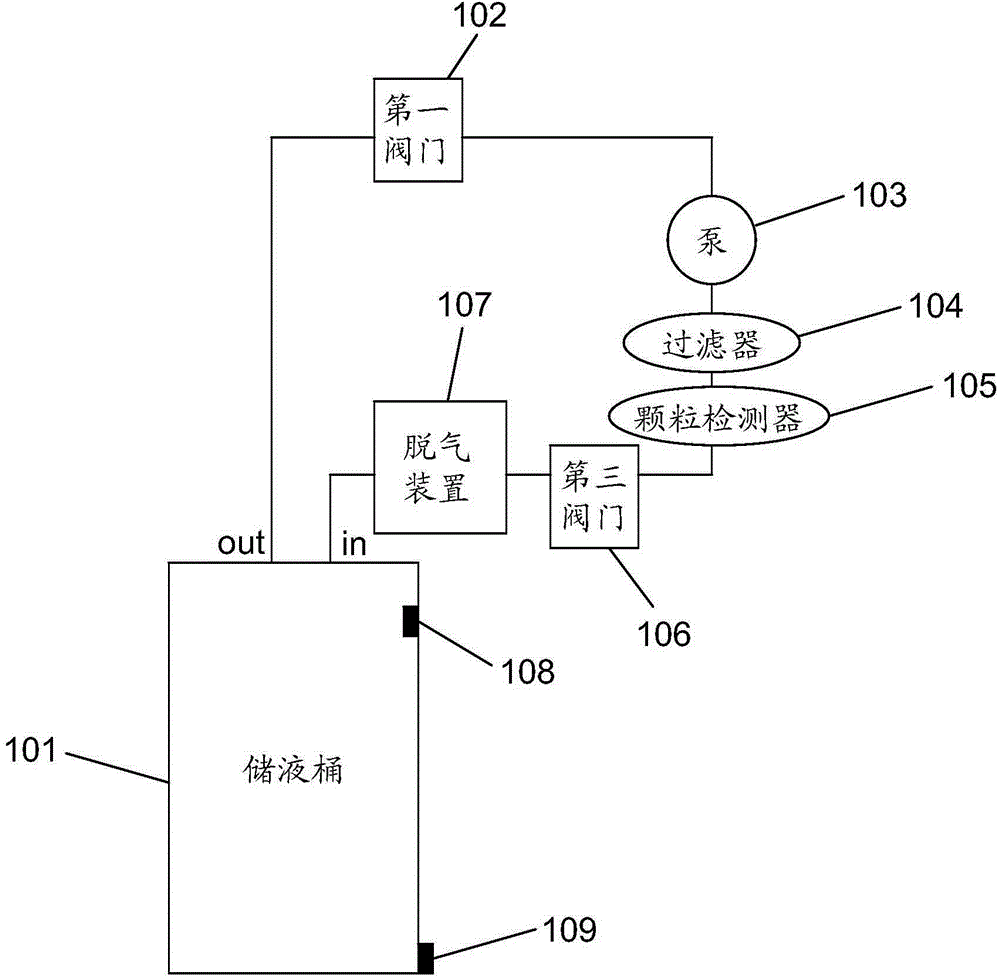

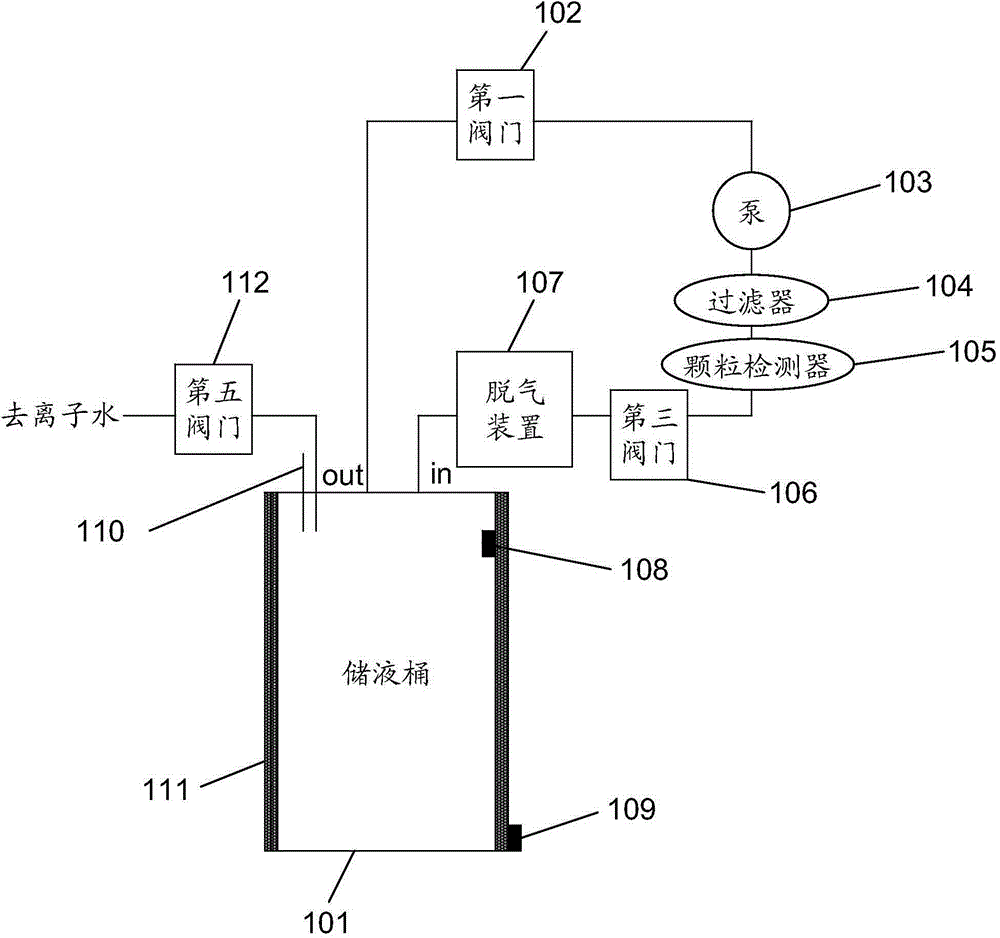

[0016] refer to figure 1 As shown, a schematic structural diagram of the polishing liquid filtering device according to the first embodiment of the present invention is disclosed. The polishing liquid filtering device includes a liquid storage barrel 101, which stores the original polishing liquid or recovered polishing liquid. The liquid storage barrel 101 is connected to the liquid inlet end of the first valve 102, the liquid outlet end of the first valve 102 is connected to the liquid inlet end of the pump 103, the liquid outlet end of the pump 103 is connected to the liquid inlet end of the filter 104, and the filter The liquid outlet of 104 is connected to the liquid inlet of the particle detector 105 , the liquid outlet of the particle detector 105 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com