Clamping valve rod packing leak-off ring inner ring taking out device and installation method thereof

A valve stem packing and removal device technology, which is applied to hand-held tools, manufacturing tools, etc., can solve problems such as difficulty in removing the inner ring, and achieve the effects of simple operation, large clamping force and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

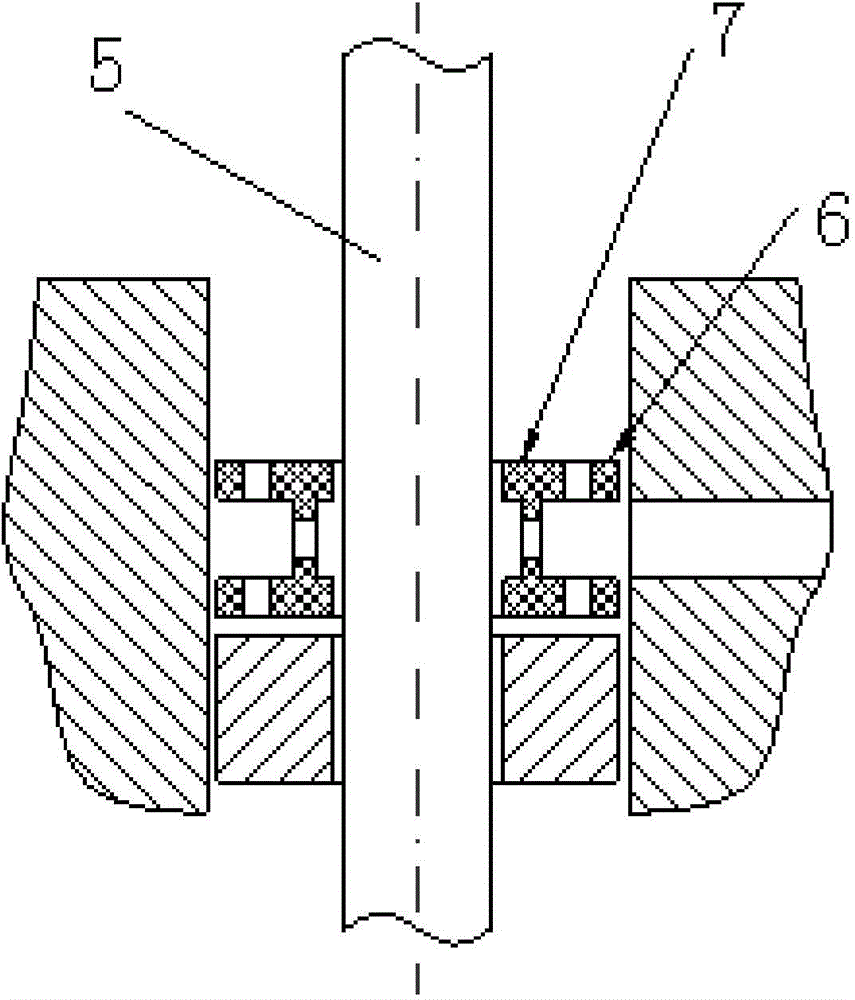

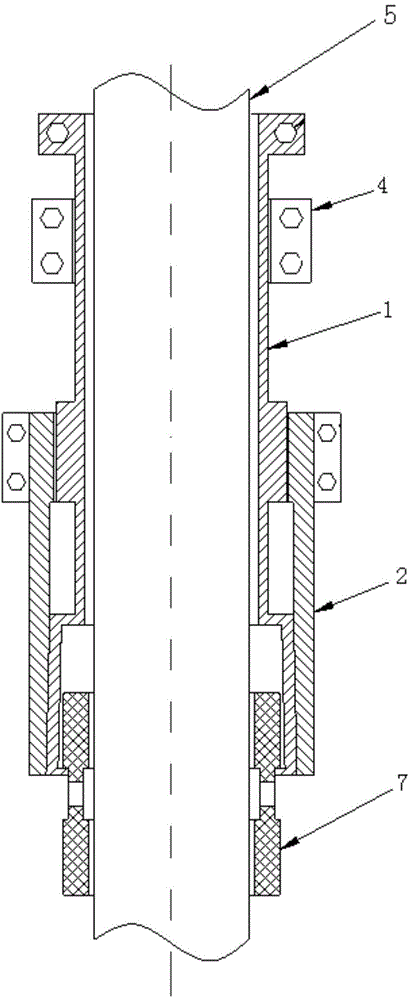

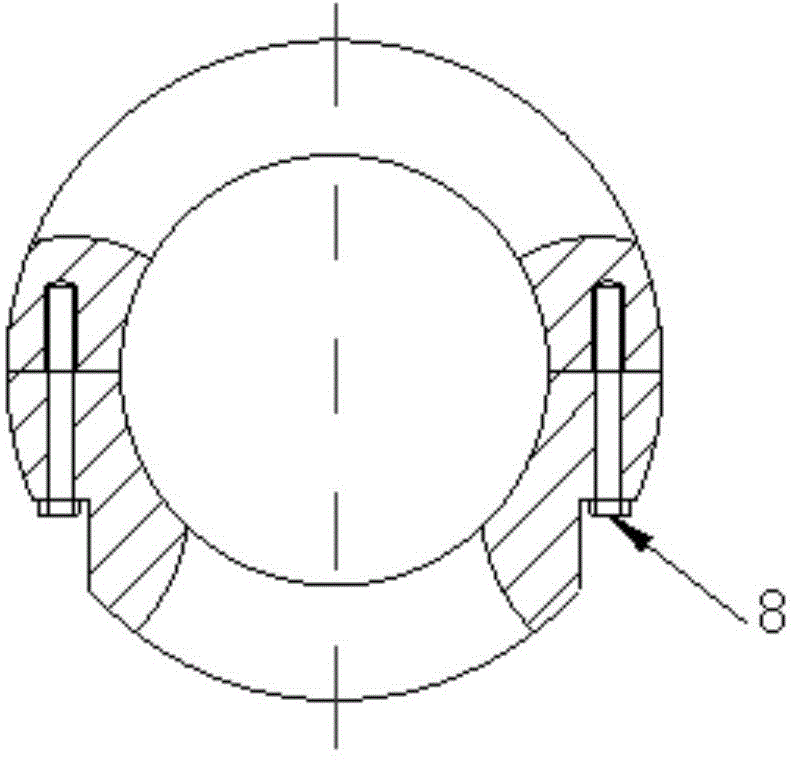

[0028] A device for taking out the inner ring of the clamping valve stem packing leakage ring, the structure of which is as follows: figure 2 As shown, it includes a tapered surface elastic claw 1, a taper sleeve 2 and a sleeve hammer 4. The tapered surface elastic claw 1, the taper sleeve 2 and the sleeve hammer 4 are all split half-ring assembly structures, and the split half-ring assembly is reliably connected by fastening screws 8, such as image 3 shown. Through on-site testing and experiments, the relevant dimensions of the tapered elastic claw 1, the tapered sleeve 2 and the sleeve hammer 4 are determined. The dimensions after connection meet the space requirements of the packing chamber, and there is a certain gap between the take-out device and the outer wall of the valve stem 5. , no jamming phenomenon will occur with the outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com