Movable plate for injection molding apparatus

An injection molding device and moving plate technology, which is applied in the direction of manufacturing tools and presses, can solve the problems of mold damage, inability to adjust the level of the movable platen, and affect the accuracy of the mold, and achieve simple structure, low cost, and height adjustment The effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

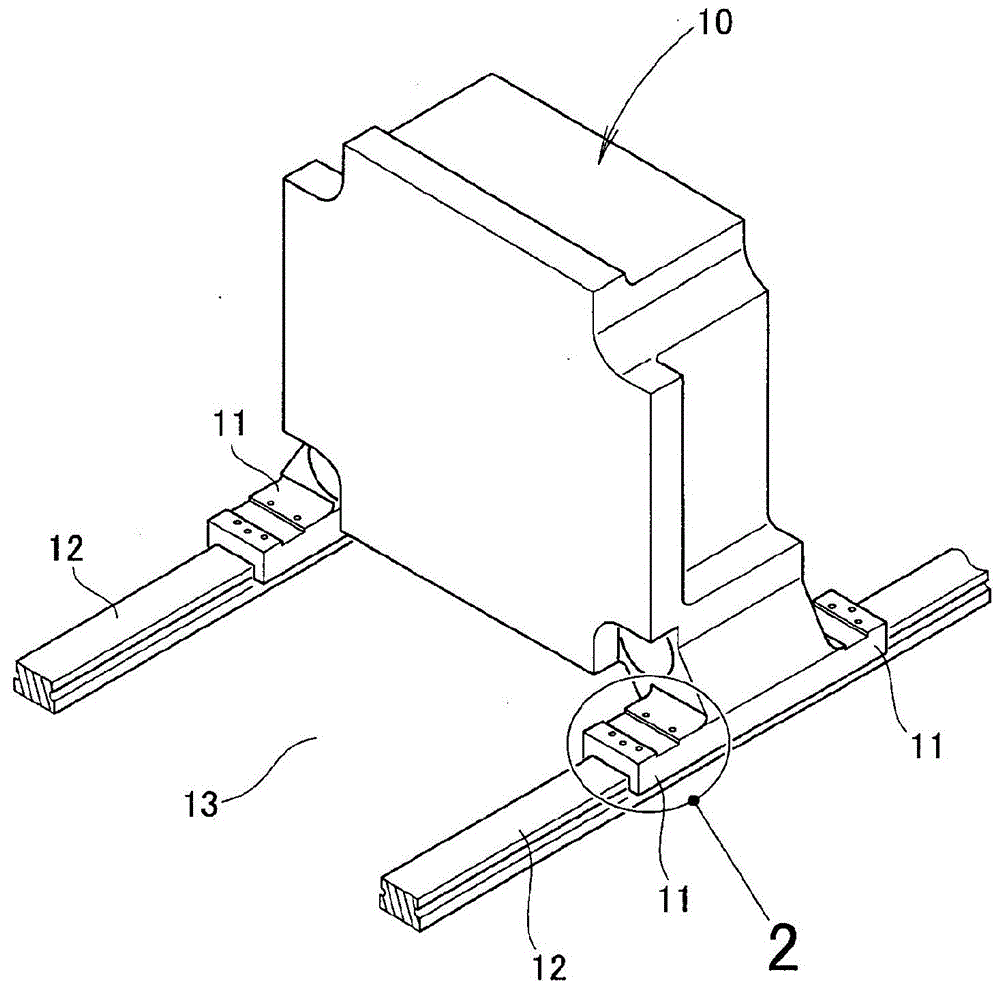

[0033] Such as figure 1 As shown, the movable panel 10 has a total of four leg portions 11 separated from each other in the width direction and in the moving direction at the lower portion. Among them, the two legs 11 , 11 are placed on the left rail 12 , and the remaining two legs 11 , 11 are placed on the right rail 12 . The left and right rails 12 , 12 are placed on a base 13 .

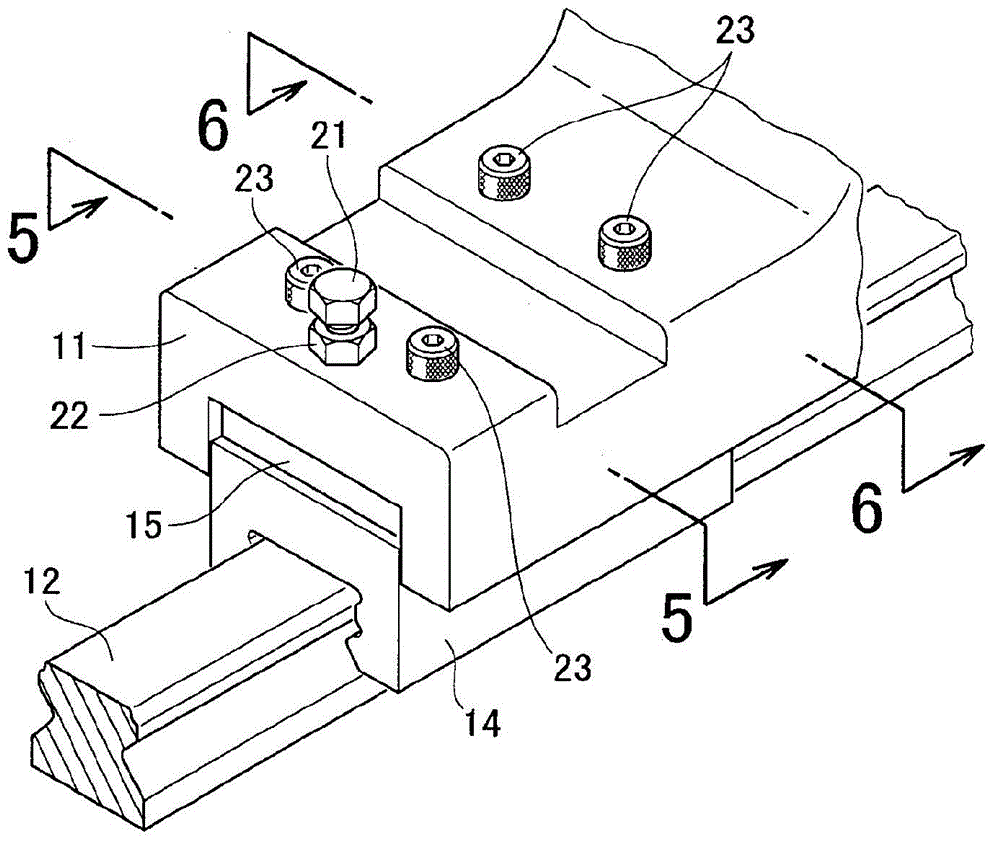

[0034] Such as figure 2 As shown, a slider 14 is fitted into the rail 12 , a flat plate 15 is placed on the slider 14 , and the leg portion 11 is placed on the flat plate 15 .

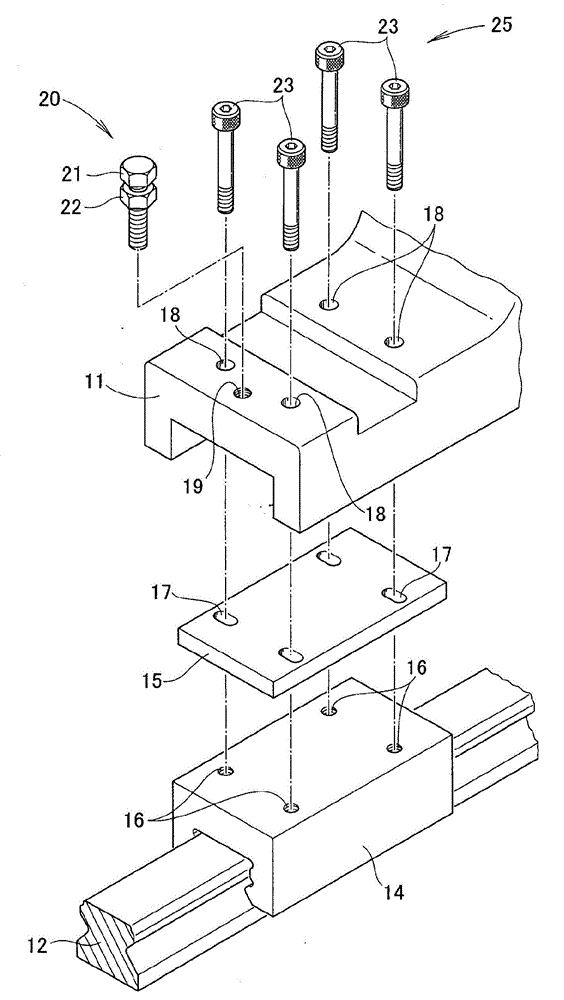

[0035] Such as image 3 As shown, the slider 14 has four internal thread parts 16 on the upper part. The four positions coincide with the vertices of the rectangle.

[0036] The plate 15 has four long holes 17 extending in the width direction (the direction perpendicular to the longitudinal direction of the rail 12).

[0037] The leg portion 11 has four bolt holes 18 and one internally threaded portion 19 arranged at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com