Linear unstretched polyethylene film easy to tear

A polyethylene film and polyethylene technology, which is applied to the types of packaging items, special packaging items, applications, etc., can solve the problems of irregular tearing openings, leakage of packaging contents, and difficulty in tearing with bare hands, achieving high sealing strength, The effect of regular tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

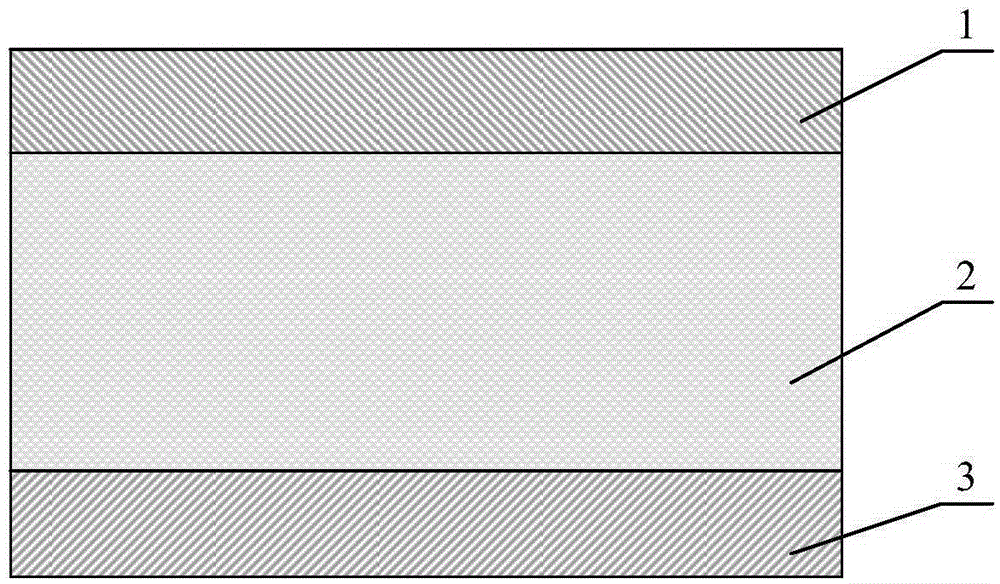

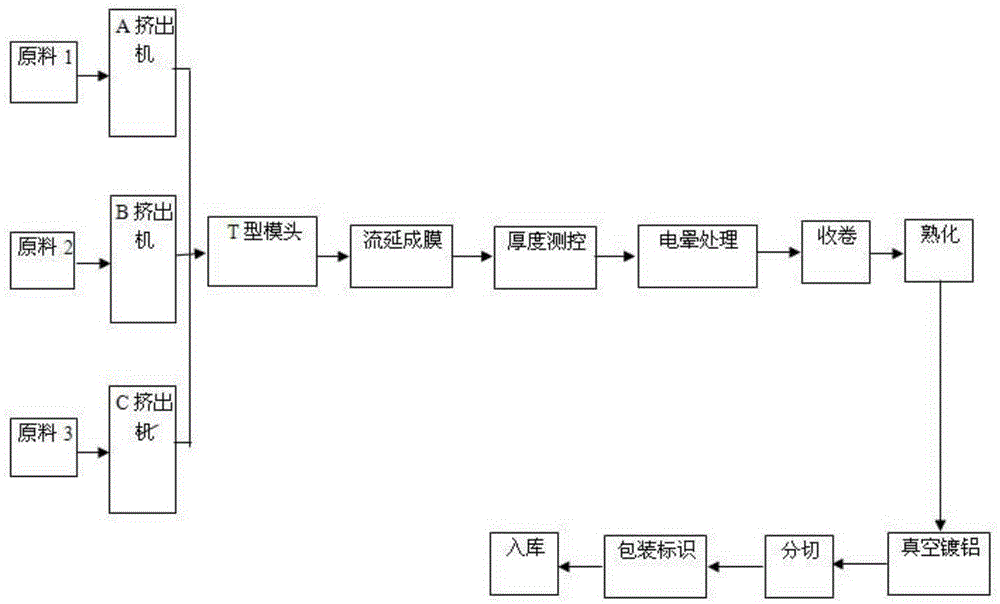

[0028] The composition of the outer layer 1 is 3wt% linear low density polyethylene + 92wt% high density polyethylene + 5wt% smooth agent; the thickness of the outer layer 1 accounts for 20% of the total thickness of the film.

[0029] The composition of the middle layer 2 is 73wt% linear low density polyethylene + 5wt% low density polyethylene + 22wt% cycloolefin copolymer; the thickness of the middle layer 2 accounts for 60% of the total thickness of the film.

[0030] The composition of the inner surface layer 3 is 3wt% low-density polyethylene, 92wt% linear low-density polyethylene and 5wt% smooth agent; the thickness of the inner surface layer 3 accounts for 20% of the total thickness of the film.

Embodiment 2

[0032] The composition of the outer layer 1 is 1wt% linear low density polyethylene + 98wt% high density polyethylene + 1wt% smooth agent; the thickness of the outer layer 1 accounts for 30% of the total thickness of the film.

[0033] The composition of the middle layer 2 is 78wt% linear low density polyethylene + 2wt% low density polyethylene + 20wt% cycloolefin copolymer; the thickness of the middle layer 2 accounts for 40% of the total thickness of the film.

[0034] The composition of the inner surface layer 3 is 2wt% low-density polyethylene, 96wt% linear low-density polyethylene and 2wt% slippery agent; the thickness of the inner surface layer 3 accounts for 30% of the total thickness of the film.

Embodiment 3

[0036] The composition of the outer layer 1 is 99wt% high-density polyethylene + 1wt% smooth agent; the thickness of the outer layer 1 accounts for 60% of the total thickness of the film.

[0037] The composition of the middle layer 2 is 82wt% linear low density polyethylene + 18wt% cycloolefin copolymer; the thickness of the middle layer 2 accounts for 10% of the total thickness of the film.

[0038] The composition of the inner surface layer 3 is 99wt% linear low density polyethylene and 1wt% smooth agent; the thickness of the inner surface layer 3 accounts for 30% of the total thickness of the film.

[0039] Wherein the main material that the present invention chooses, linear low-density polyethylene is Mobil 1002YB type, does not contain anti-adhesive agent and smooth agent, or Hanwha 3224 type contains anti-adhesive agent and smooth agent; Low-density polyethylene is Qatar Petrochemical FD0274, Contain anti-adhesive and slip agent, or Qatar Petrochemical FD0270, without a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com