Sucker

A suction cup and disc-shaped technology, applied in the field of suction cup structure, can solve problems such as loss of suction force, and achieve the effect of increasing load and excellent suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

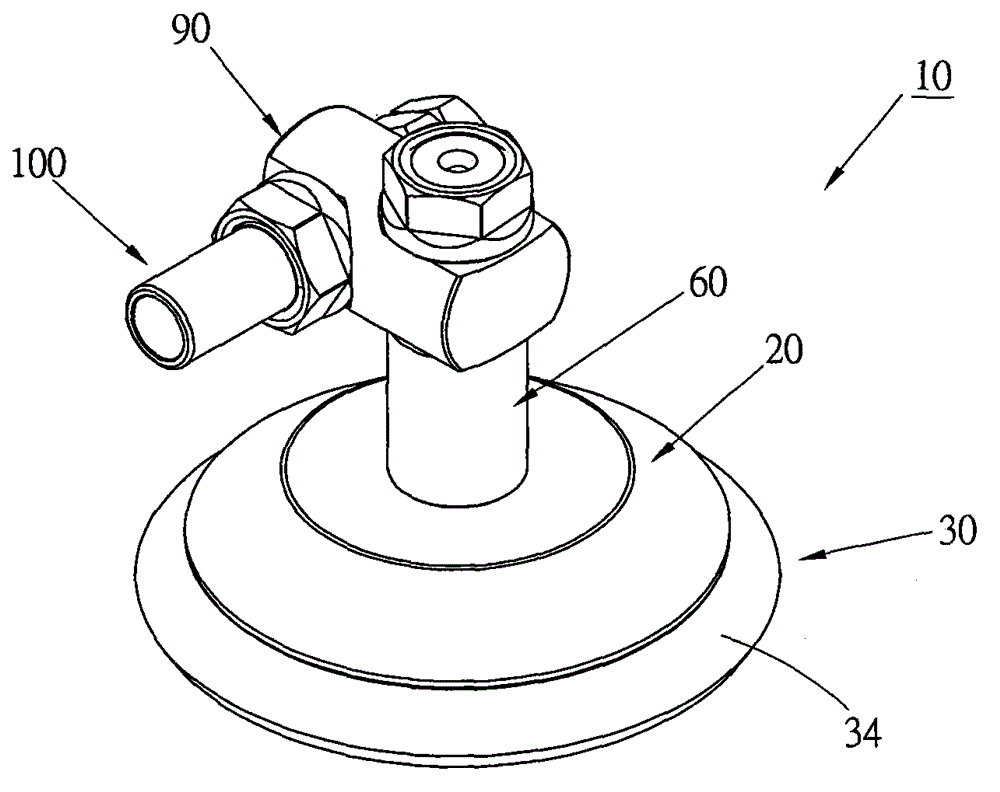

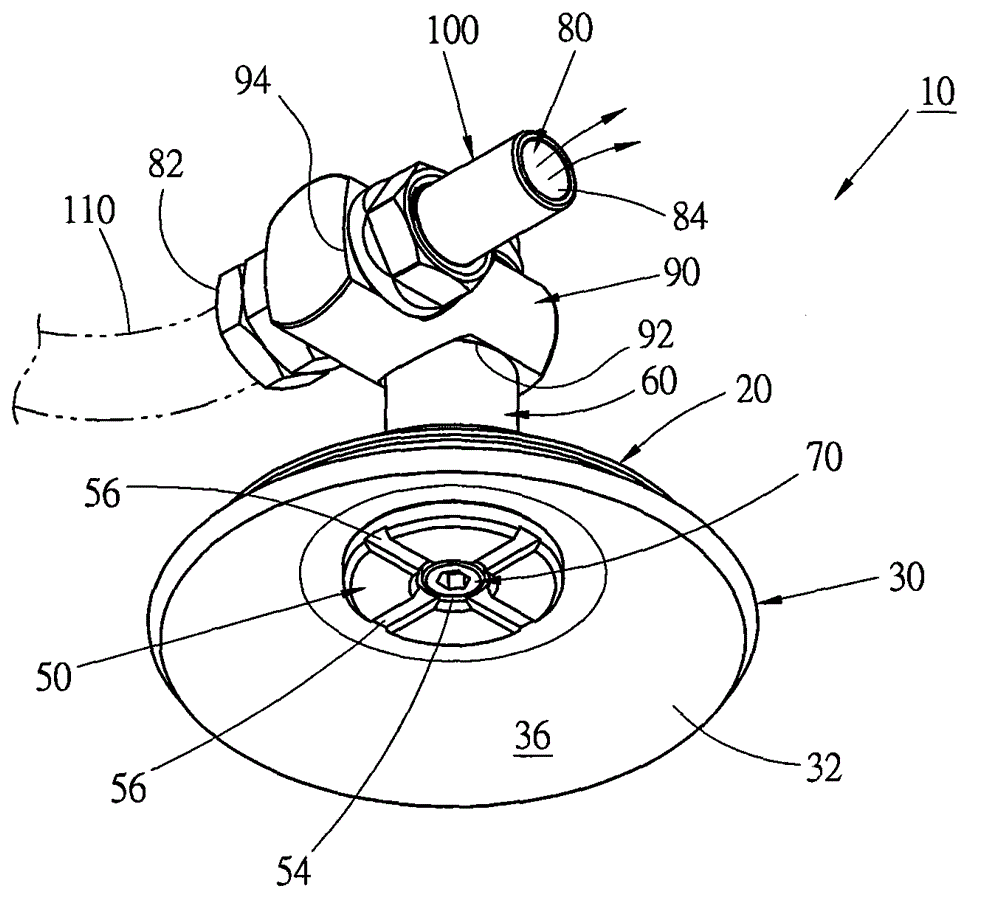

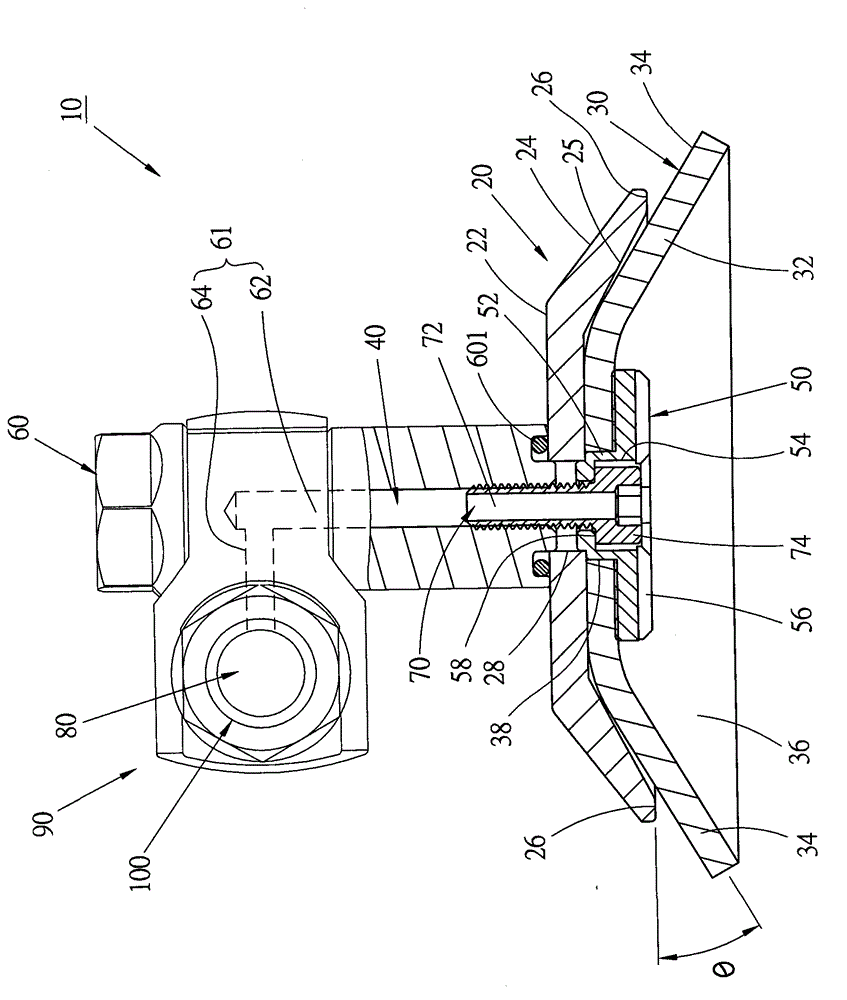

[0026] see Figure 1 to Figure 3 , The suction cup 10 provided by the first preferred embodiment of the present invention mainly includes: a main body 20 , a soft disk body 30 and an air suction channel 40 .

[0027] The body 20 is disc-shaped and made of hard material. It has a flat inner disc portion 22 and an outer disc portion 24 connected to the outer periphery of the inner disc portion 22. The bottom surface of the outer disc portion forms a downward and outwardly inclined The conical surface makes the bottom surface of the main body form a concave conical or conical chamber 25. The bottom surface of the main body 20 is further provided with an annular contact surface 26 connected to the periphery of the container chamber 25 . Preferably, the annular abutment surface 26 is a plane; making the abutment surface an inclined surface can also be an implementation choice. The abutting surface 26 of this embodiment is a horizontal plane.

[0028] The disc body 30 is a disc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com