Premixing apparatus

一种预混合、空气供应的技术,应用在气体燃料燃烧器、燃烧方法、燃烧类型等方向,能够解决燃料气体吸引力变弱、增大燃气供应路通气阻力、混合气体空燃比分布不均等问题,达到防止分布不均的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

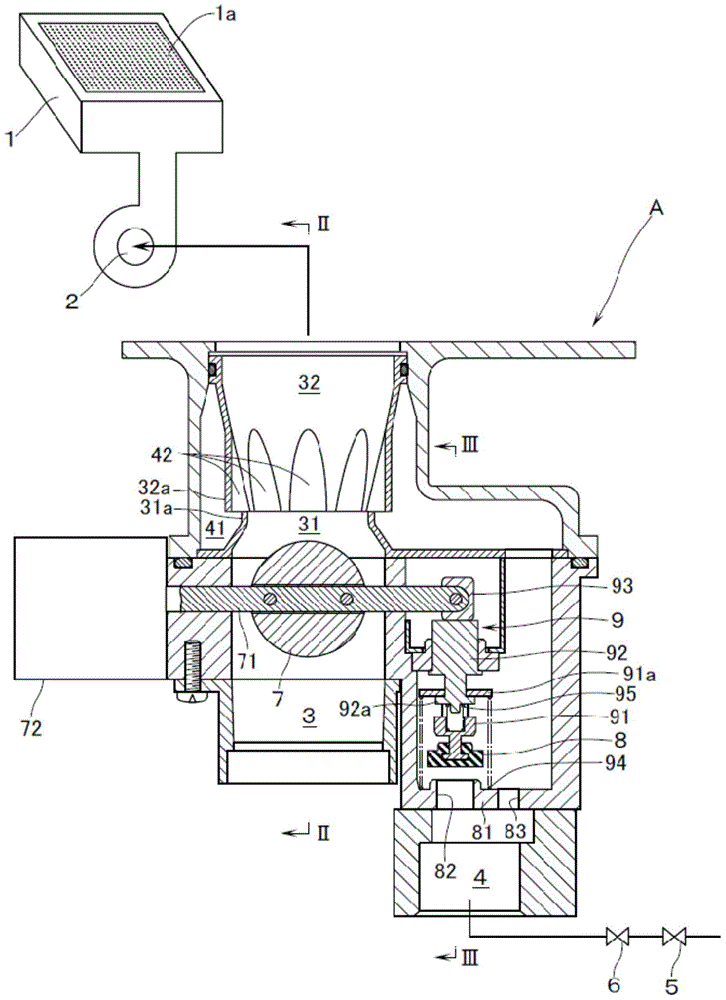

[0022] refer to figure 1 , 1 is a burner composed of an all-primary combustion burner, etc., and the burner has a combustion surface 1a for ejecting and burning the mixed gas. The blower 2 is connected to the burner 1, and the fuel gas is mixed with the air by the premixing device A according to the embodiment of the present invention, and the mixed gas is supplied to the burner 1 through the blower 2 .

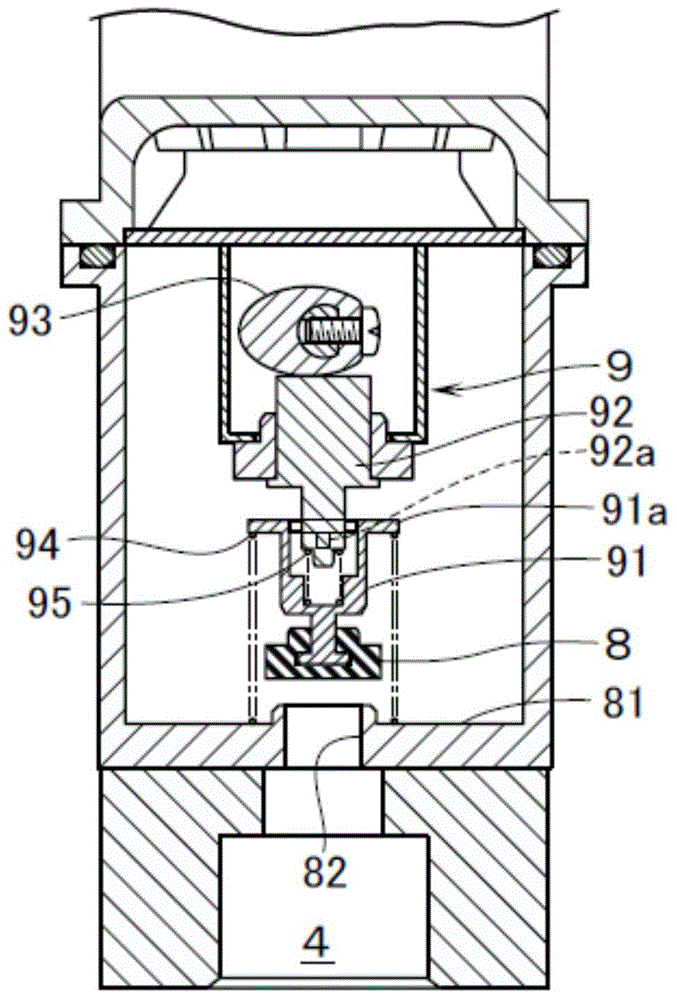

[0023] The premixing device A includes an air supply passage 3 on the upstream side of the blower 2 and a gas supply passage 4 for supplying fuel gas. On the upstream portion of the gas supply path 4, an on-off valve 5 and a flow rate regulating valve 6 composed of a proportional valve or a zero pressure regulator are provided. In addition, the premixing device A has: an air resistance conversion mechanism for converting the magnitude of the ventilation resistance of the air supply passage 3; Gas resistance conversion mechanism.

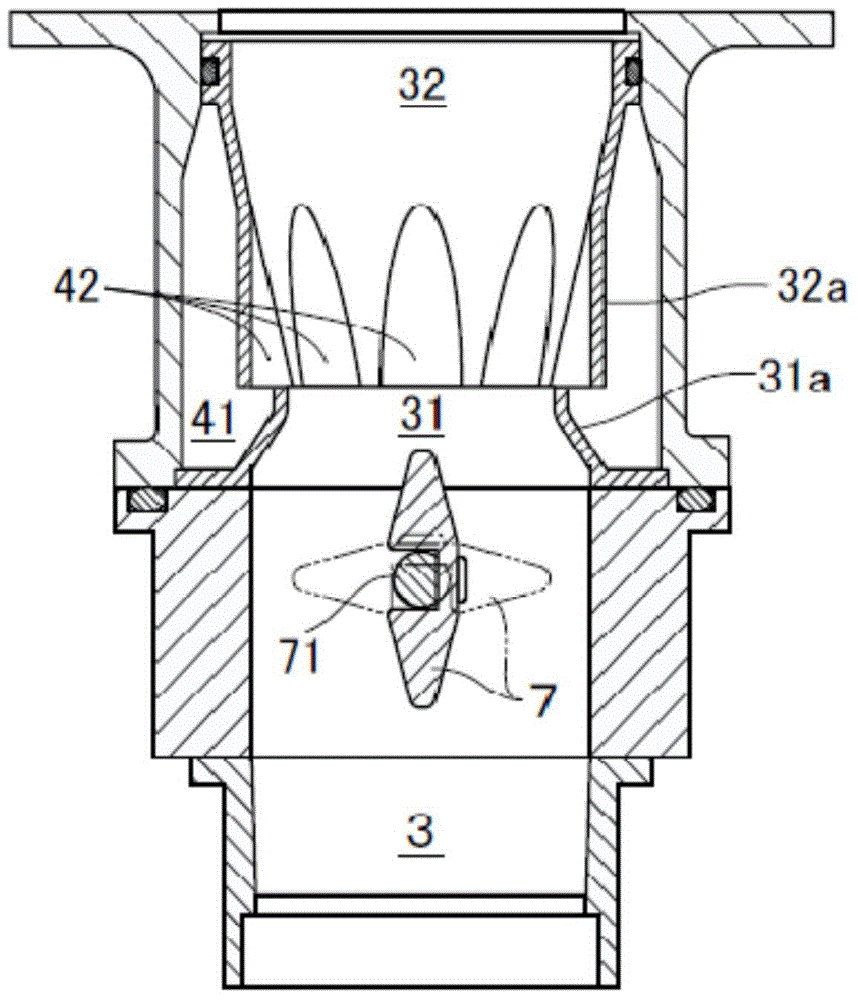

[0024] refer to figure 2 The air resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com