Tri-mode probe with automatic skew adjustment

A three-mode, probe technology, applied to the parts, instruments, and measuring devices of electrical measuring instruments, can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the drawings, which are not necessarily to scale, like or corresponding elements of the disclosed systems and methods are indicated by like reference numerals.

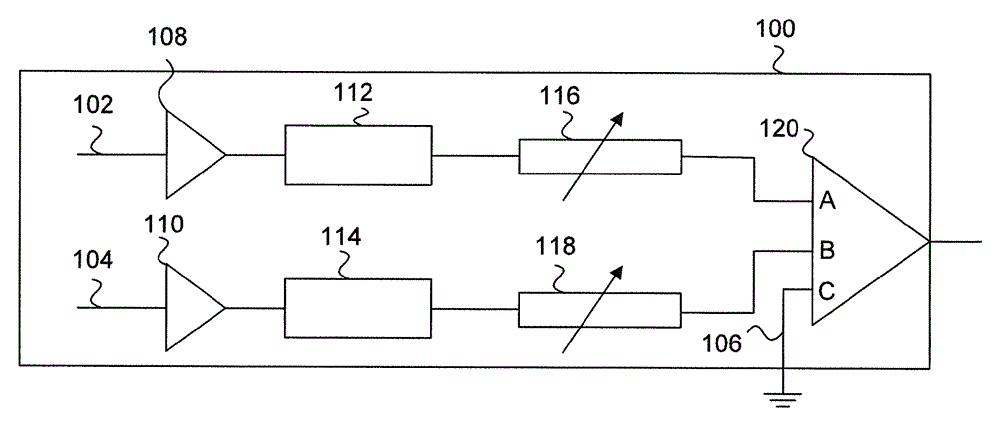

[0019] The disclosed technology involves probes with electronically adjustable delays. Preferably, the probe has electronically adjustable delays in each input path. However, as disclosed in more detail below, some embodiments include an electronically adjustable delay in one input path while the other input has a fixed delay. Probes can be as figure 1 TriMode for a single channel using a test and measurement instrument as shown in TM Probe 100.

[0020] In some embodiments, TriMode TM Probe 100 includes three inputs 102 , 104 and 106 . A first input 102 receives a first signal from the device under test, a second input 104 receives a second signal from the device under test, and a third input 106 is connected to ground. TriMode TM Probe 100 also includes buffers 108 and 110 , cables 112 and 114 , adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com