Wire harness

A wire harness and main wire technology, applied in the field of wire harnesses, can solve the problems of increasing the cost of components and wire harnesses, reducing the mass production capacity of wire harnesses, etc., to achieve the effect of preventing waste and clear details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, a first embodiment of the present invention is described with reference to the drawings.

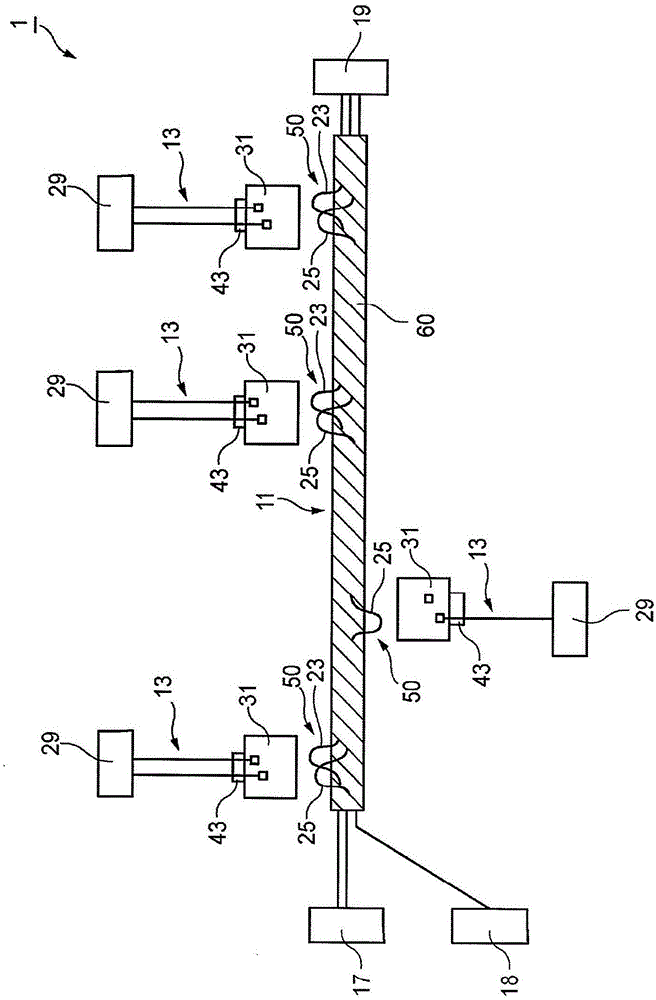

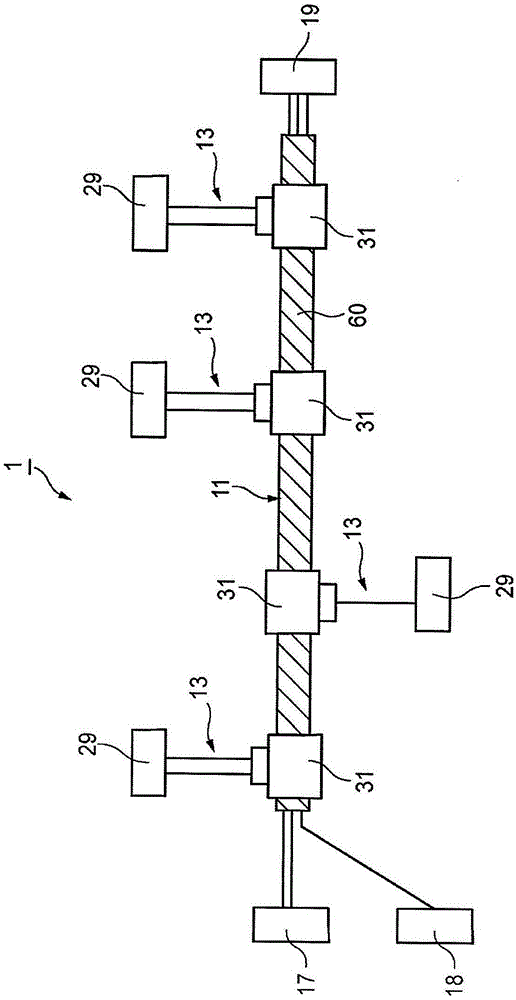

[0053] figure 1 is a schematic diagram of a wire harness according to a first embodiment of the present invention.

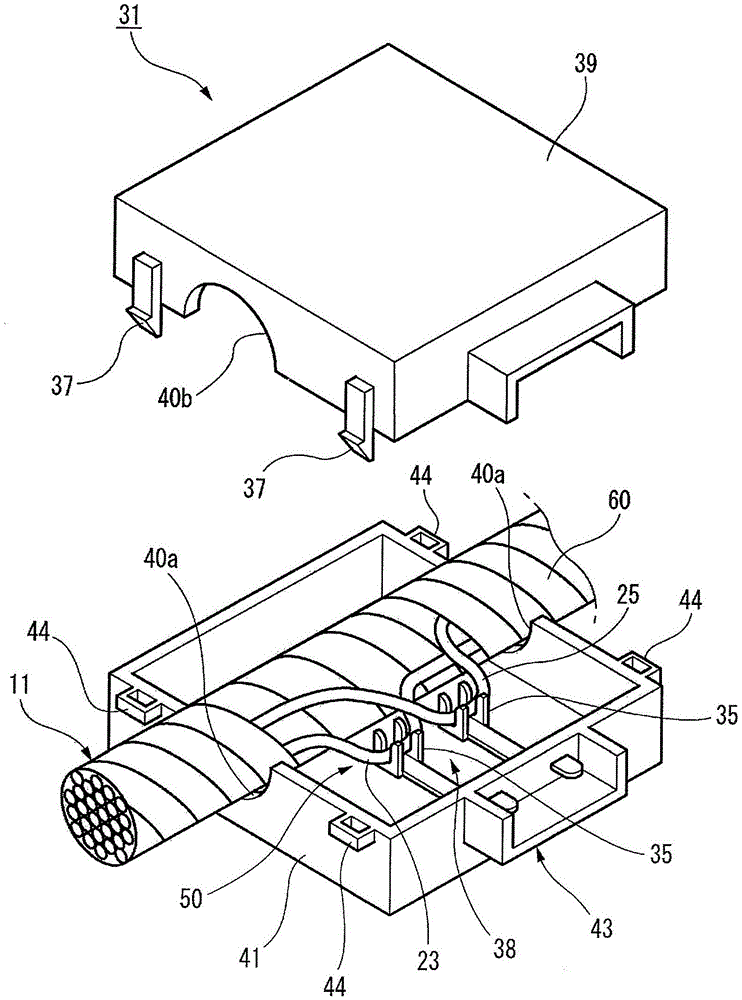

[0054] The wire harness 1 of the first embodiment has a main wire harness 11 to which a first end of an additional connecting member 13 is connected in a branched manner later.

[0055] figure 1 The main wire harness 11 shown is a bundle of four basic types of main wires, including power wires 23, communication wires 25, signal wires, and ground (GND) wires 27, and the main wire harness 11 can be universally installed in multiple installations. in the target vehicle. The main harness 11 is connected to a plurality of electrical devices (for example, a storage battery 17 and a junction box 19 ) and a connector 18 . Such as figure 1 As shown, the insulating tape 60 is wound on the outer circumference of the bundled electric wires of the main wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com