Method for online rapid arc alignment of arc-shaped square billet continuous casting machine crystallizer and movable section

A billet continuous casting and crystallizer technology, applied in the field of metallurgical rolling, can solve the problems of low adjustment accuracy of the jack, low positioning accuracy of the positioning pin, and influence on the accuracy and speed of the arc, so as to reduce steel breakout accidents and maintenance costs, High measurement and adjustment accuracy, and the effect of improving the accuracy of arc alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

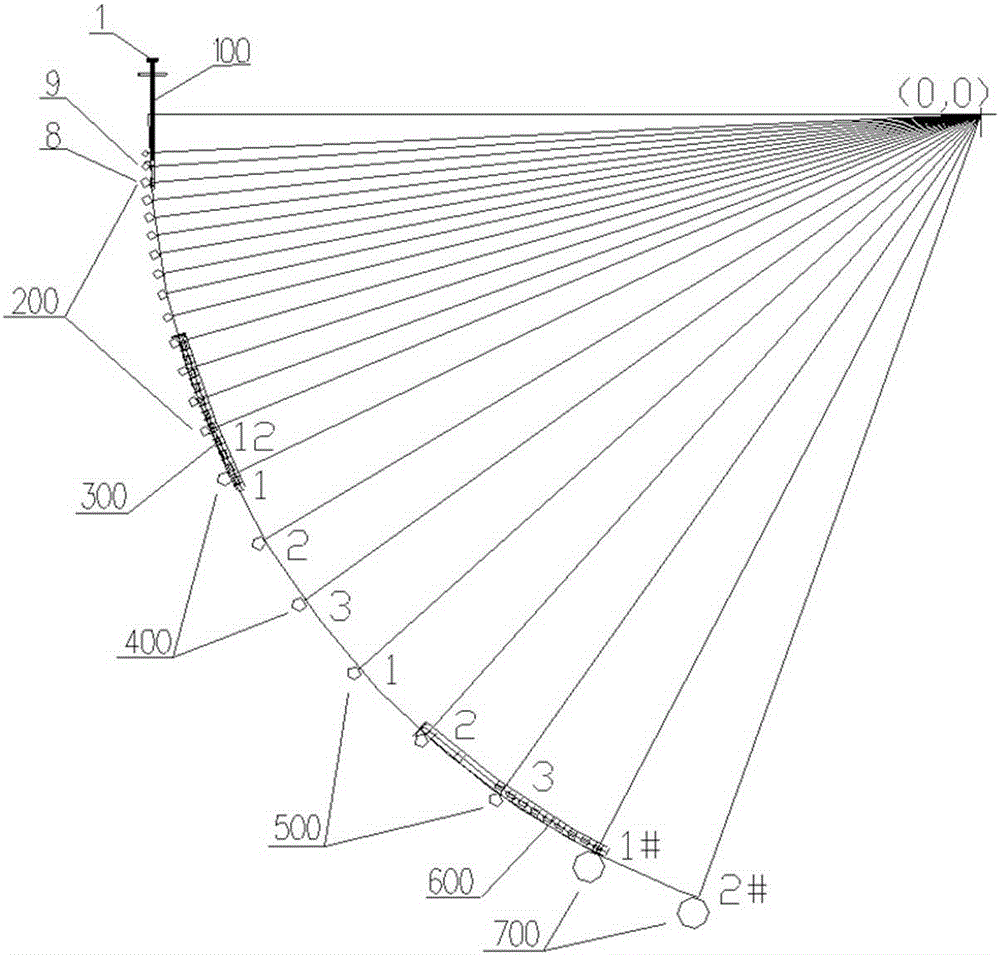

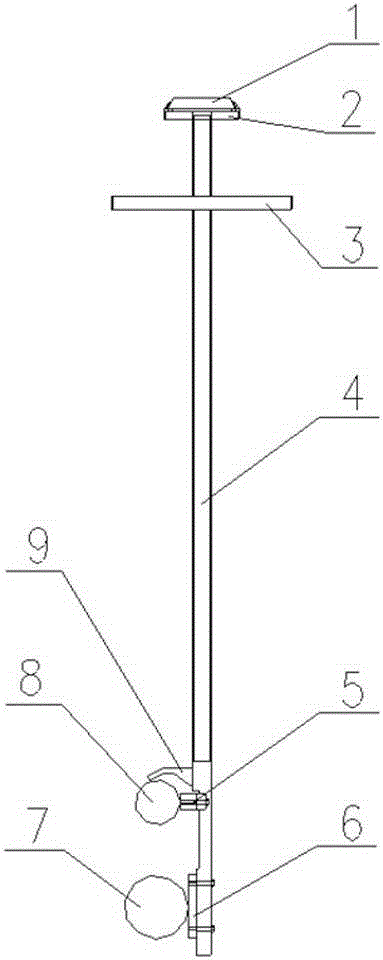

[0026] Such as figure 1 and 2 As shown, take the arc alignment of the 230×230mm section and the online movable section of the R12m billet continuous casting machine in the steelmaking plant of Kunming Iron and Steel New District as an example. The off-line arc adjustment method of different sections of other arc-shaped billet continuous casting machines can be deduced by analogy.

[0027] Tools and materials used in the inventive method (unit: mm):

[0028] 1 piece of online arc-alignment model between the crystallizer and the movable section, 1 piece of strip level with 0.5mm / m accuracy, and 4 types of copper gaskets: 0.02, 0.05, 0.10, 0.20 each; Q235-A arc-aligning gaskets There are 5 types: 0.20, 0.50, 1.00, 2.00, and 5.00 each with several pieces. The selection of specific gaskets can be flexibly adjusted according to the dimensional accuracy requirements of the movable section.

[0029] On-line arc matching method between crystallizer and movable section:

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com