Novel fan-shaped section 0 section of fully-arc-shaped slab continuous casting machine

A slab continuous casting and arc-shaped technology, which is applied in the field of iron and steel metallurgy, can solve the problems of high labor intensity, cumbersome adjustment procedures, and complicated connection methods, and achieve the effects of simple adjustment, simplified connection methods, and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

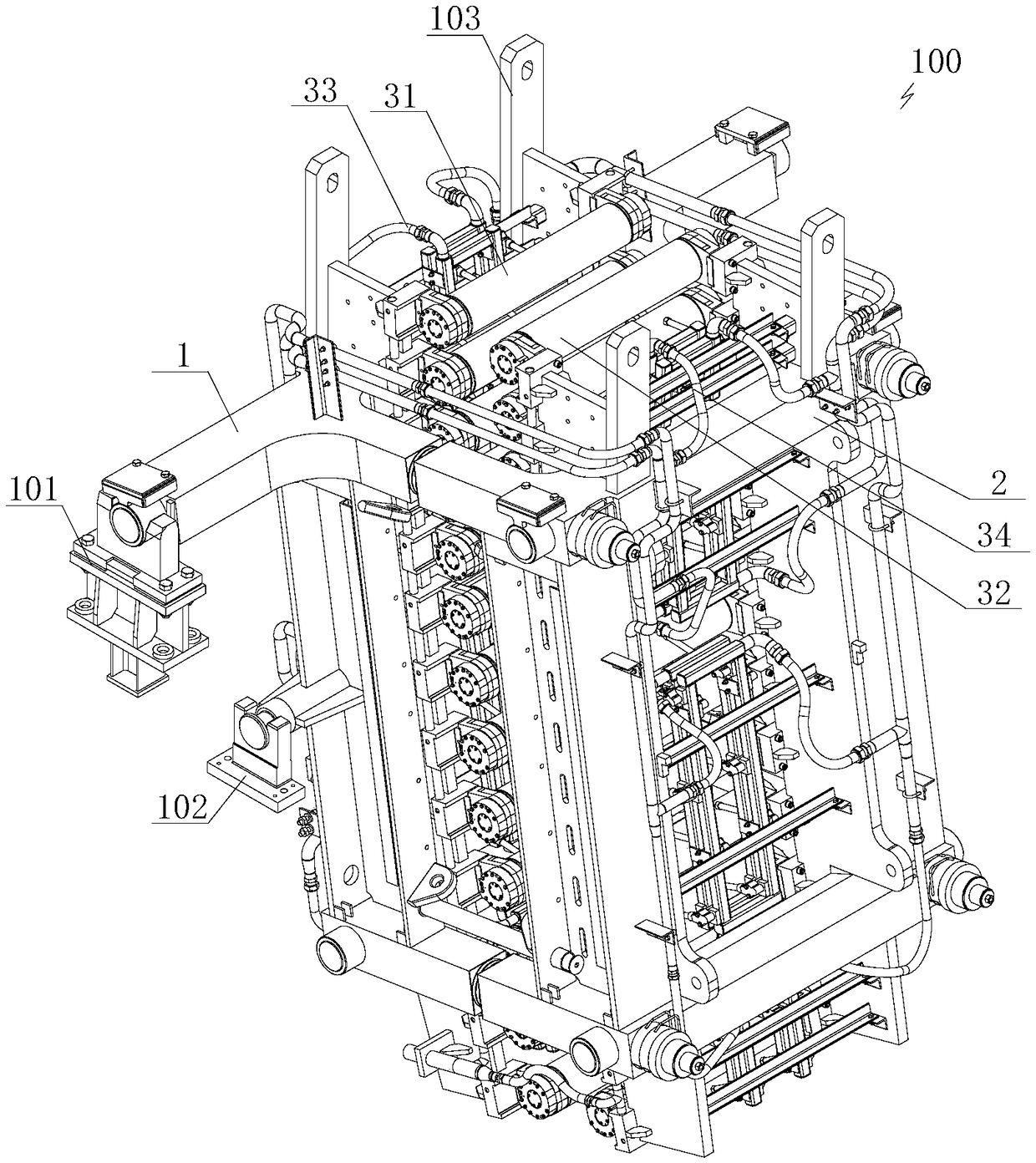

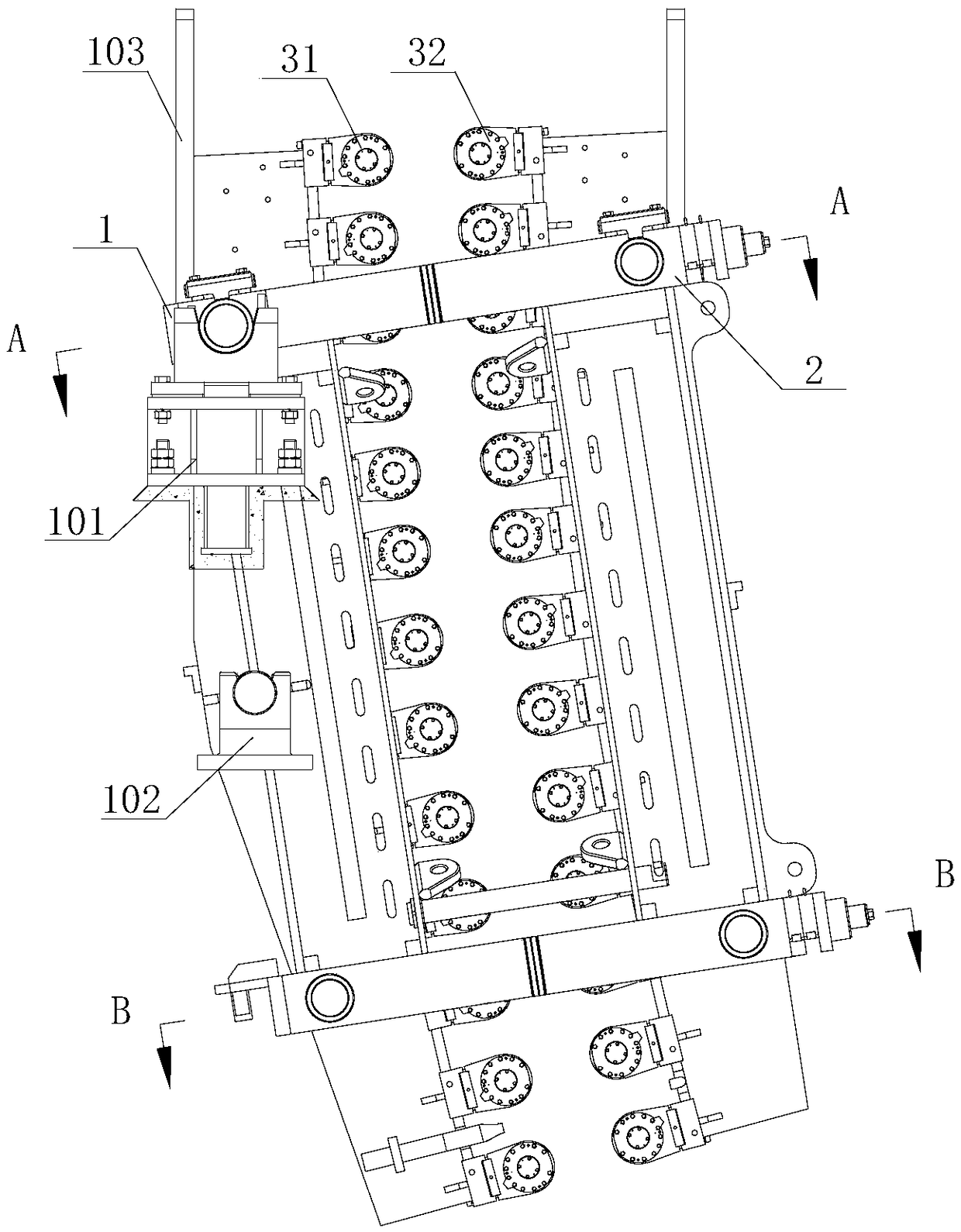

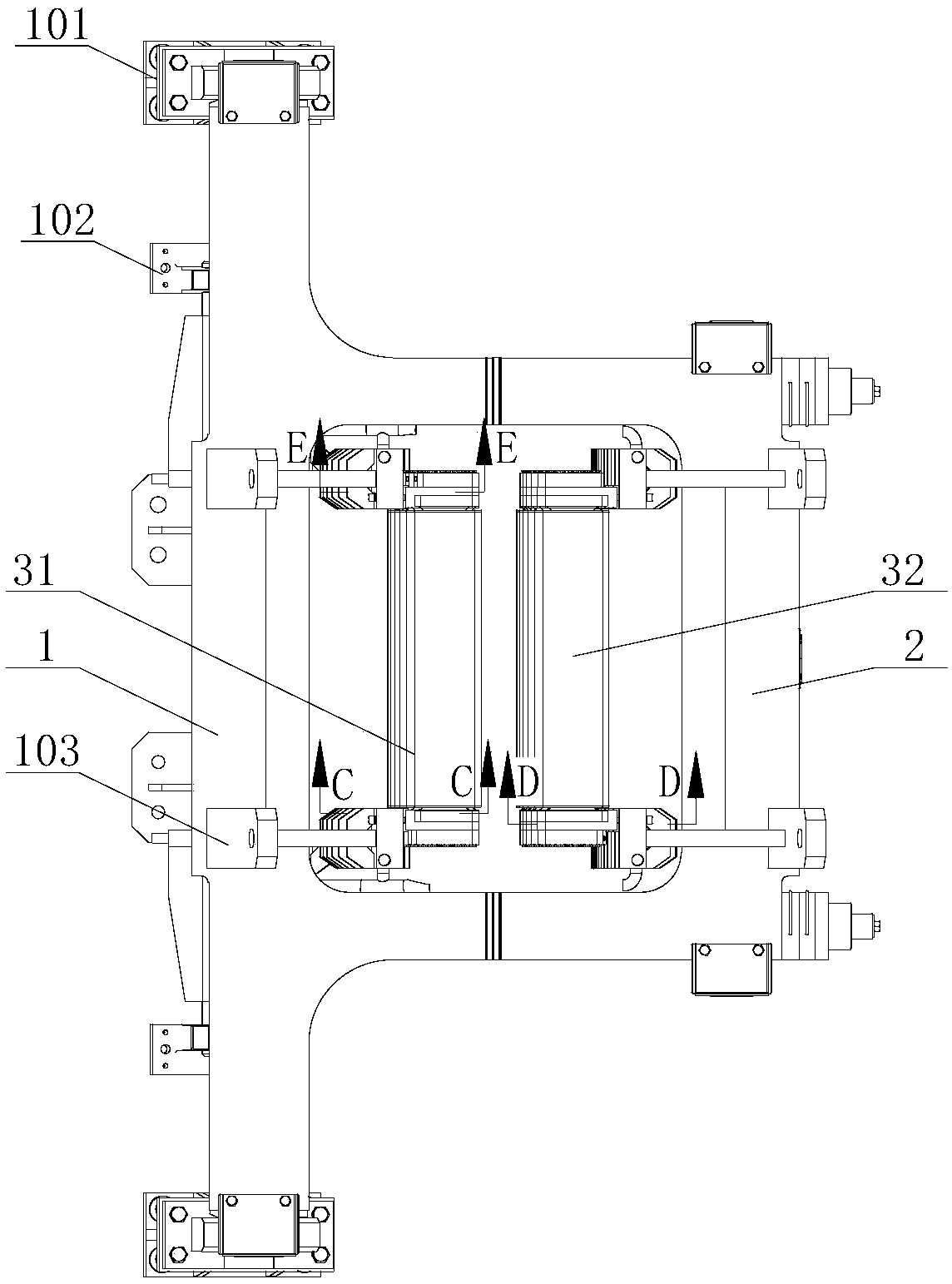

[0059] Such as Figure 1 to Figure 12 As shown, the present invention provides a novel full-arc slab continuous casting machine segment 0 section 100, which includes an outer arc frame 1 and an inner arc frame 2 arranged in a C shape, and a row of outer arc rollers 31 are hinged inside the outer arc frame 1 , the inner arc frame 2 is hinged with a row of inner arc rollers 32 that can be arranged opposite to the outer arc rollers 31, and the outer arc frame 1 and the inner arc frame 2 can be fixedly connected by adjusting the opening degree and taper; the outer arc rollers 31 and the inner arc Water-cooling passages that can communicate with external water sources are arranged in the arc rollers 32 .

[0060] The segment 0 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com