Automatic screw-in device for screws

A screw and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unstable posture, screw stuck, screw deflection, etc., and achieve the effect of improving the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

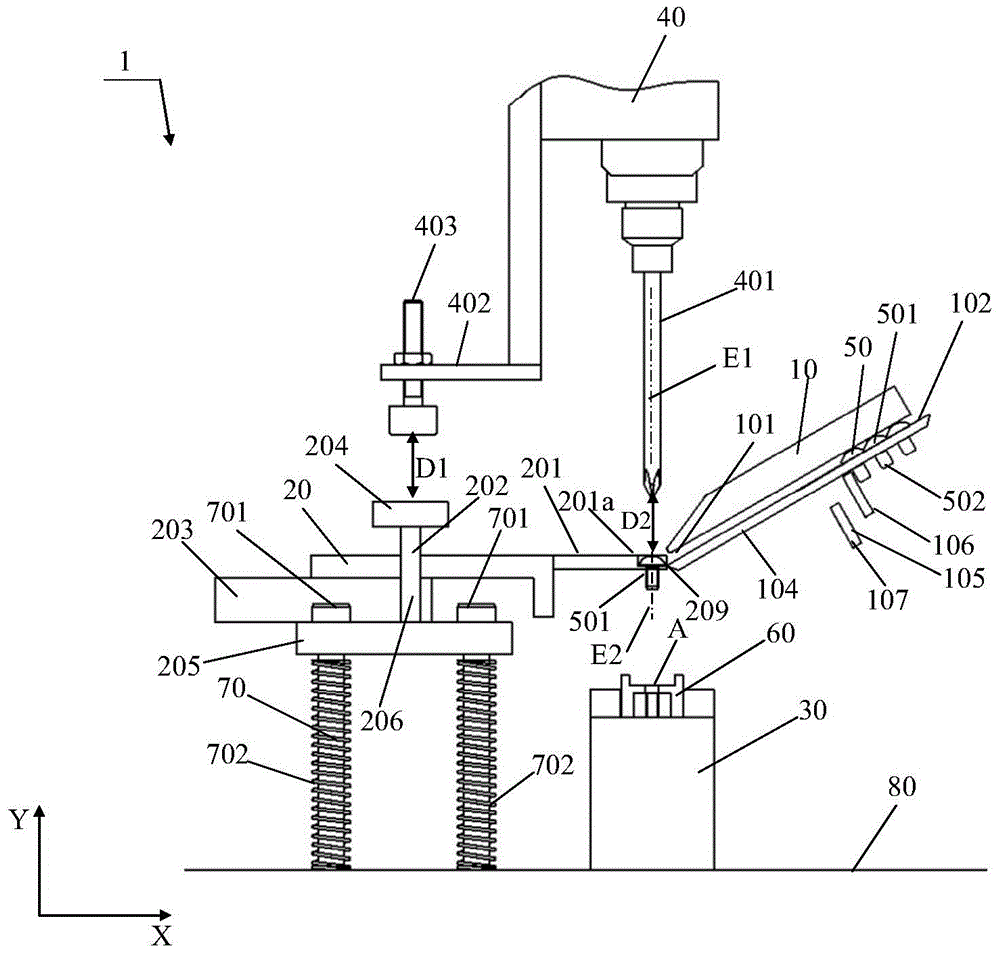

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. Here, in the description of the drawings, the same reference numerals are assigned to the same or corresponding elements, and overlapping descriptions are omitted.

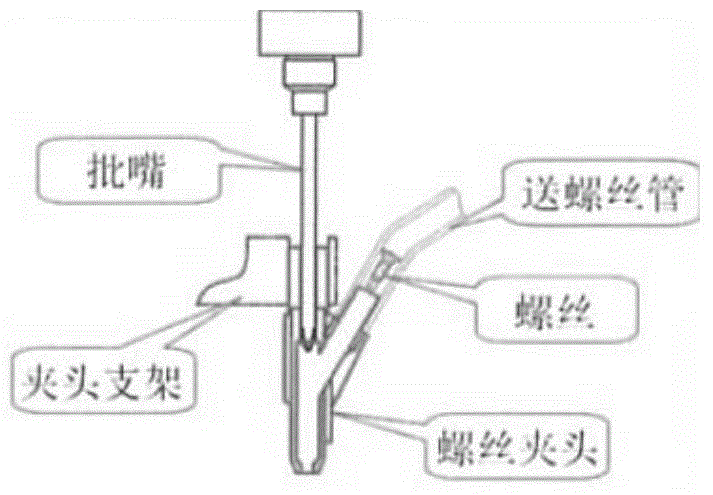

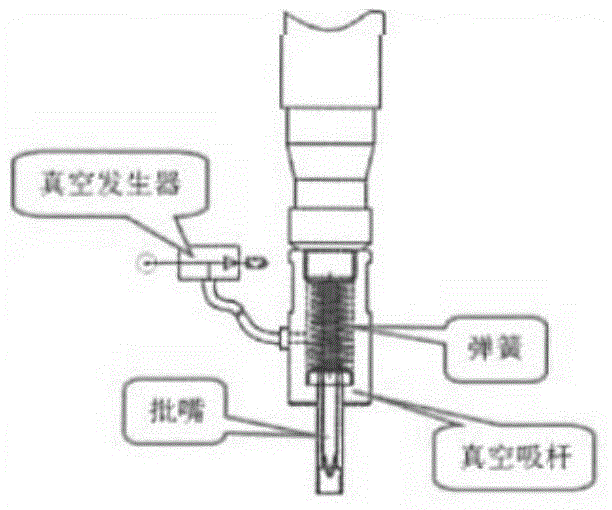

[0033] Figure 3 ~ Figure 8 It is a configuration diagram showing each state during operation of the automatic screw driving device according to the present embodiment. Figure 9 ~ Figure 10It is a schematic diagram which shows the rough structure of the screw conveying mechanism of the automatic screw driving apparatus which concerns on this embodiment. Figure 11 It is a schematic diagram which shows the rough structure of the holding part of the screw holding mechanism of the automatic screw driving apparatus concerning this embodiment. exist Figure 3 ~ Figure 8 In the shown rectangular coordinate system, the X-axis represents the horizontal direction, and the Y-axis represents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com