A device manufacturing method

A technology of equipment manufacturing and equipment, which is applied in the field of equipment manufacturing, can solve problems such as the reduction of nut pull-out force and twist-off force, the nut column becomes brittle, and cannot meet the design requirements, and achieves the effect of optimizing the pull-out force and twist-off force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiment of the present application provides a manufacturing method, which is used to solve the technical problems in the prior art that the nut column becomes brittle, resulting in a reduction in the pulling force and twisting force of the nut, and even fails to meet the design requirements. Change the brittleness of the nut column, optimize the pulling force and twisting force of the nut to the maximum, and meet the technical effect of the design requirements.

[0033] The technical solution in the embodiment of the present application is to solve the above problems, and the general idea is as follows:

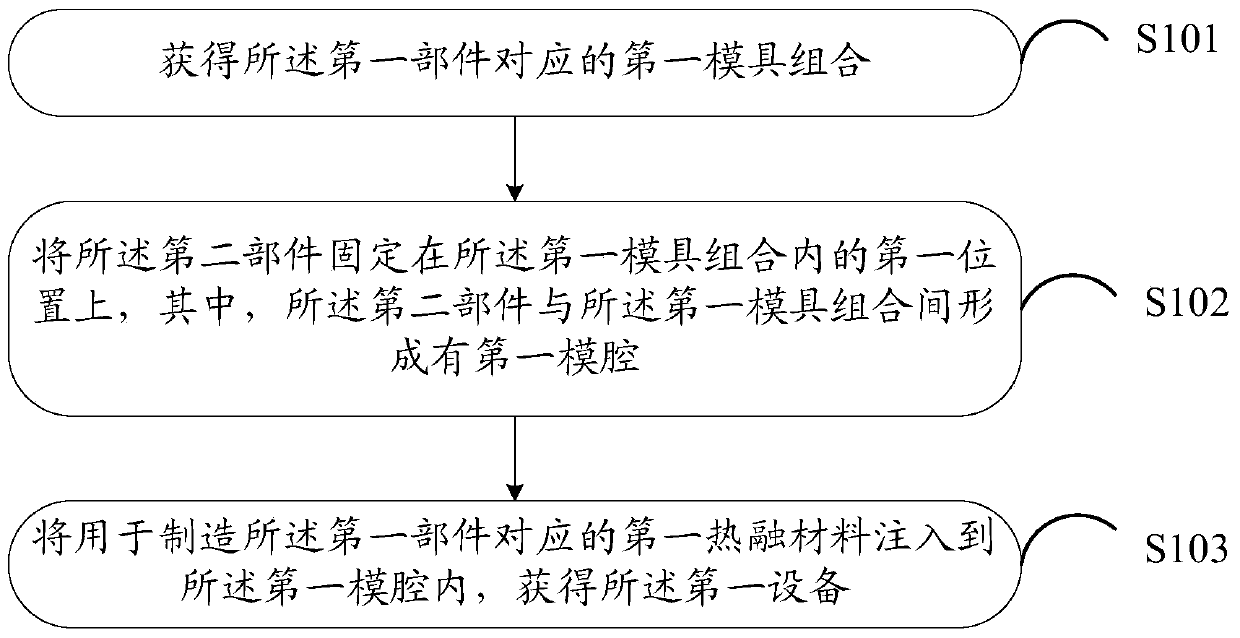

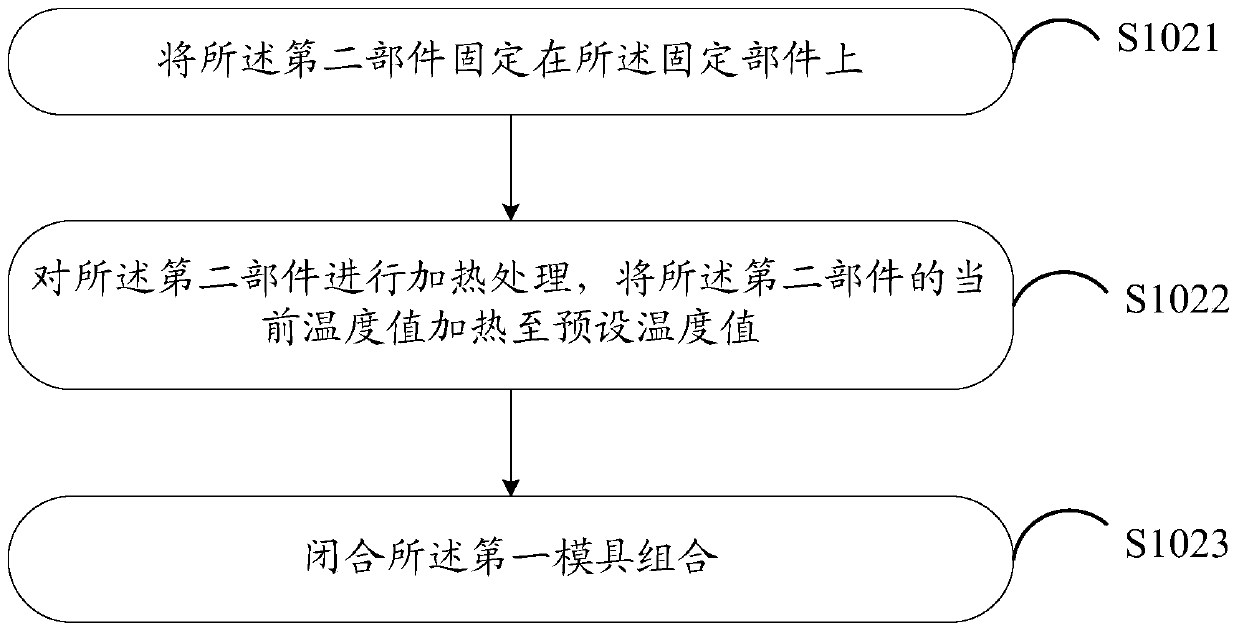

[0034] A manufacturing method for manufacturing a first device comprising a first component and a second component, the method comprising: obtaining a first mold combination corresponding to the first component; fixing the second component on the first In a first position in a mold combination, wherein a first mold cavity is formed between the second component a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com