Bagging machine

A bagging machine and bagging technology, applied to the bagging machine for feed packaging and the field of grain, can solve the problems of physical injury, high labor intensity, and large occupied area, and achieve the convenience of production and manufacturing, improve work efficiency, and occupy an area small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings.

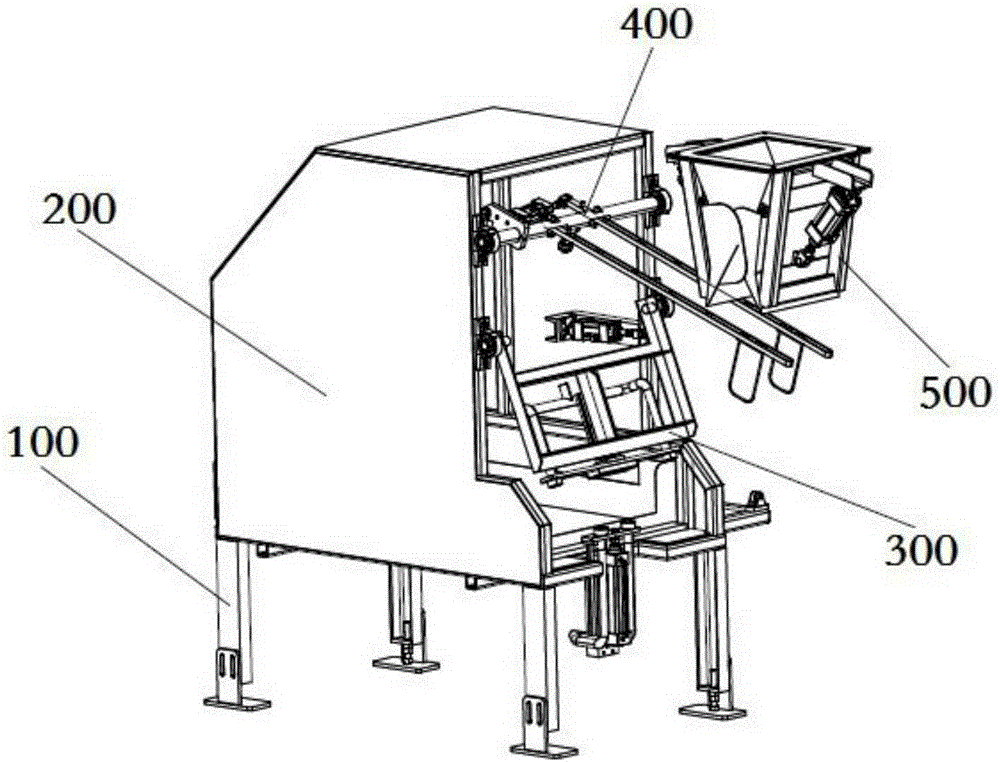

[0039] refer to figure 1 , which is a schematic diagram of the three-dimensional structure of the bagging machine of the present invention. In this embodiment, the bagging machine of the present invention includes a supporting chassis 100 , a casing 200 , a suction bag portion 300 , a bagging portion 400 and a bag clamping portion 500 . Wherein the casing 200 is disposed above the support chassis 100 .

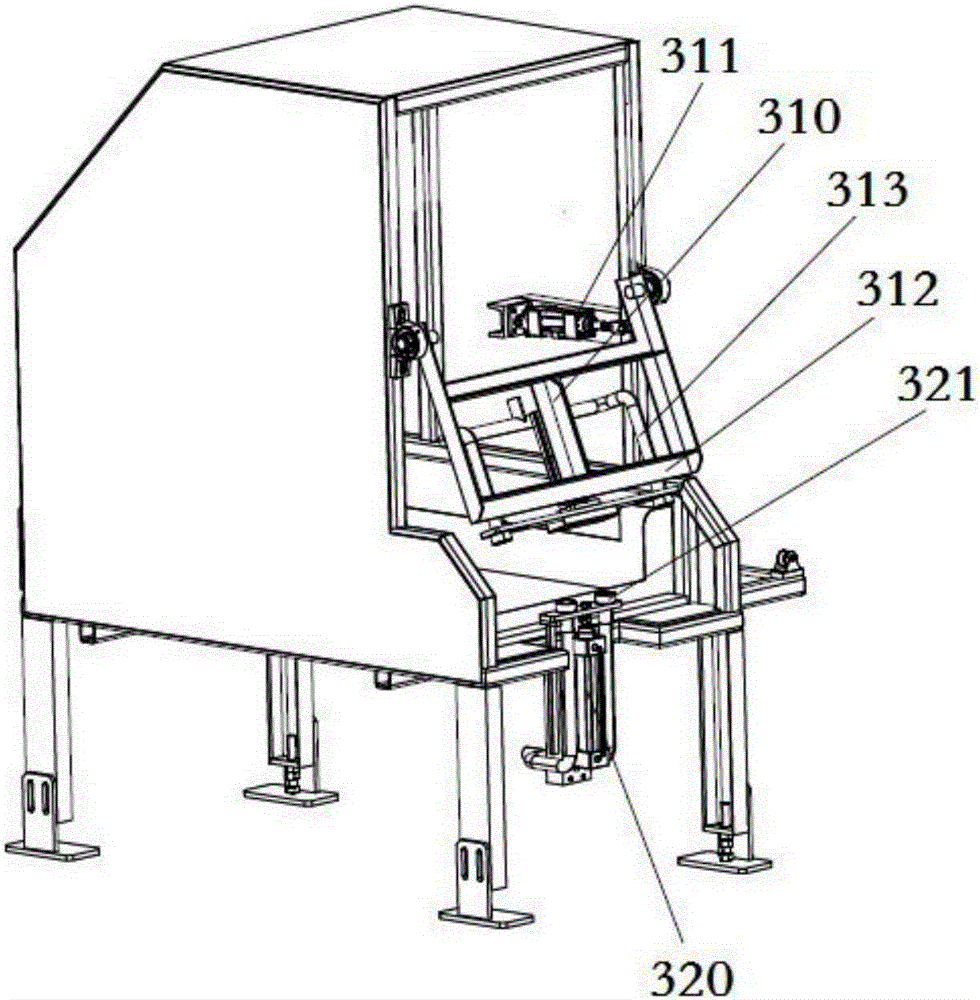

[0040] refer to figure 2 , which is a schematic structural diagram of the suction bag unit 300 in the bagging machine. In this embodiment, the suction bag unit 300 includes an upper suction bag device 310 and a lower suction bag device 320 . The upper suction bag device 310 includes a suction bag cylinder 311 , a movable support 312 and an upper suction duct...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap