Double-stopping side conveying belt

A double-sided, conveyor belt technology, used in conveyors, transportation and packaging, etc., to meet the needs of precise transmission, easy to use, and simple in structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

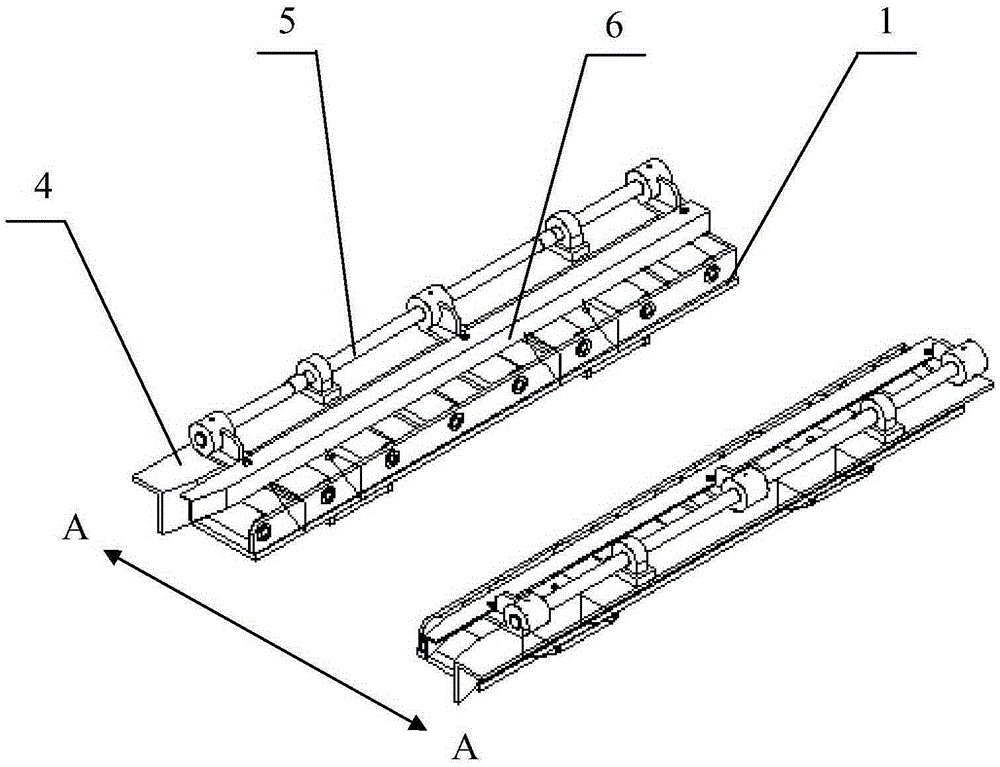

[0016] The present invention is a double-wall conveyor belt. The conveyor belt has two pairs of walls with different distances. Through switching, it can meet the transmission requirements of two different sizes of finished articles, and solves the problem that the existing wall-type conveyor belts only Suitable for the technical problem of conveying a single size item.

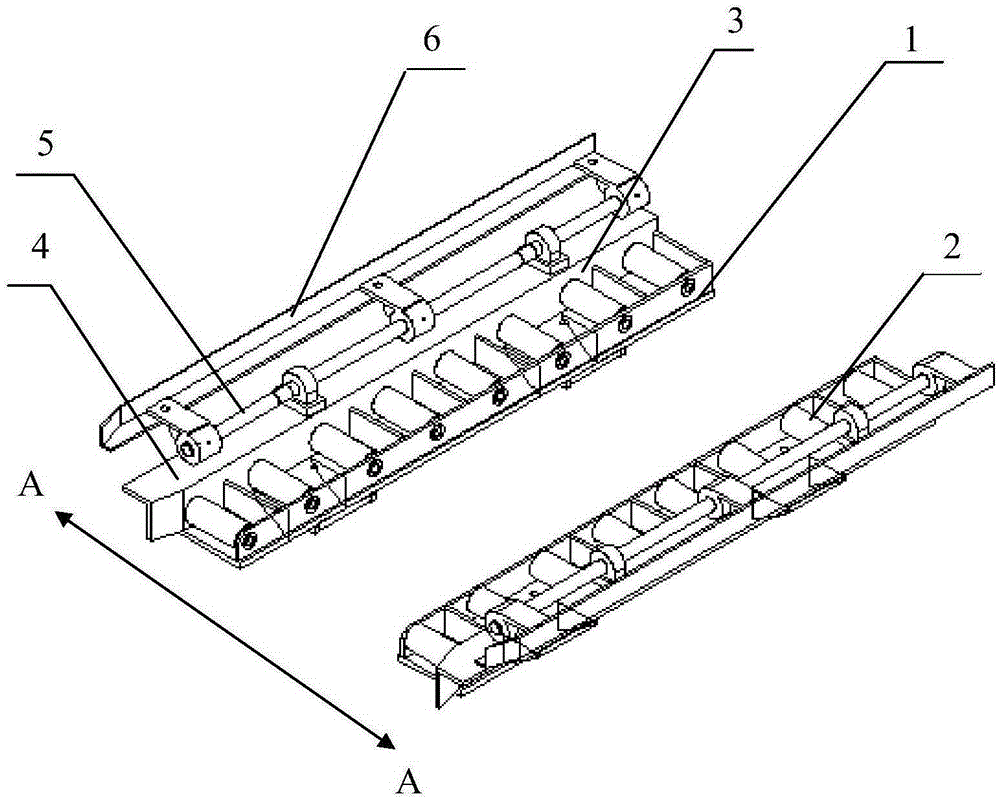

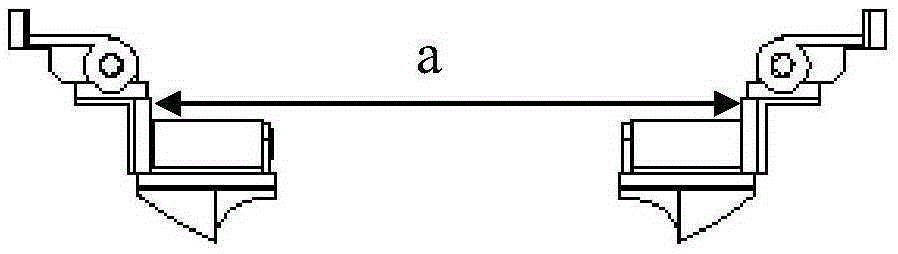

[0017] In a specific embodiment, the double-rib conveyor belt of the present invention includes a bottom plate 1, and multiple sets of rolling shafts 2 evenly arranged on the upper surface of the bottom plate 1, and these uniformly arranged rolling shafts 2 form a conveyor belt In other embodiments, other structures such as belts and chains can also be used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com