Active heave compensation device for air winch and control method thereof

A technology of pneumatic winch and heave compensation, applied in the direction of hoisting device, spring mechanism, etc., can solve the problem that the pneumatic winch cannot exert its advantages, and achieve the effect of widening the working field and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

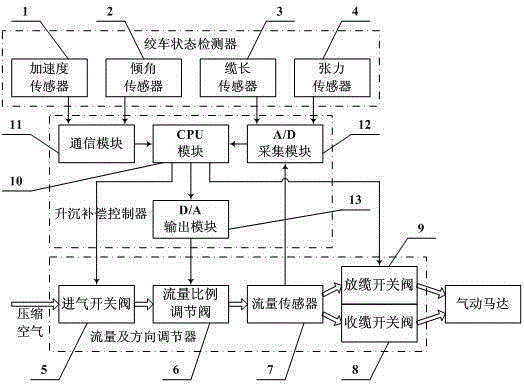

[0027] The purpose of the present invention is to provide an active heave compensation device for a pneumatic winch, which is mainly composed of three parts: a winch state detector, a flow and direction regulator, and a heave compensation controller. , tension detection, air intake flow adjustment, direction speed control and other functions, the overall block diagram is as follows figure 1 shown.

[0028] 1. Winch status detector

[0029] It is mainly composed of acceleration sensor 1, inclination sensor 2, cable length sensor 3, and tension sensor 4. Acceleration sensor 1 and inclination sensor 2 are installed at the bottom of the base of the pneumatic winch to realize the acquisition of parameters such as acceleration and inclination angle of the heave movement of the pneumatic winch Cable length sensor 3 and tension sensor 4 are installed on the detection assembly of the pneumatic winch cable discharge mechanism to detect parameters such as cable length and tension when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com