A well-shaped slider trolley for electroplating traveling

A kind of electroplating driving, well-shaped technology, applied in the direction of electrolytic coatings, etc., can solve the problems of short service life, poor guiding accuracy, poor running stability, etc., to improve the load condition, increase service life, and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

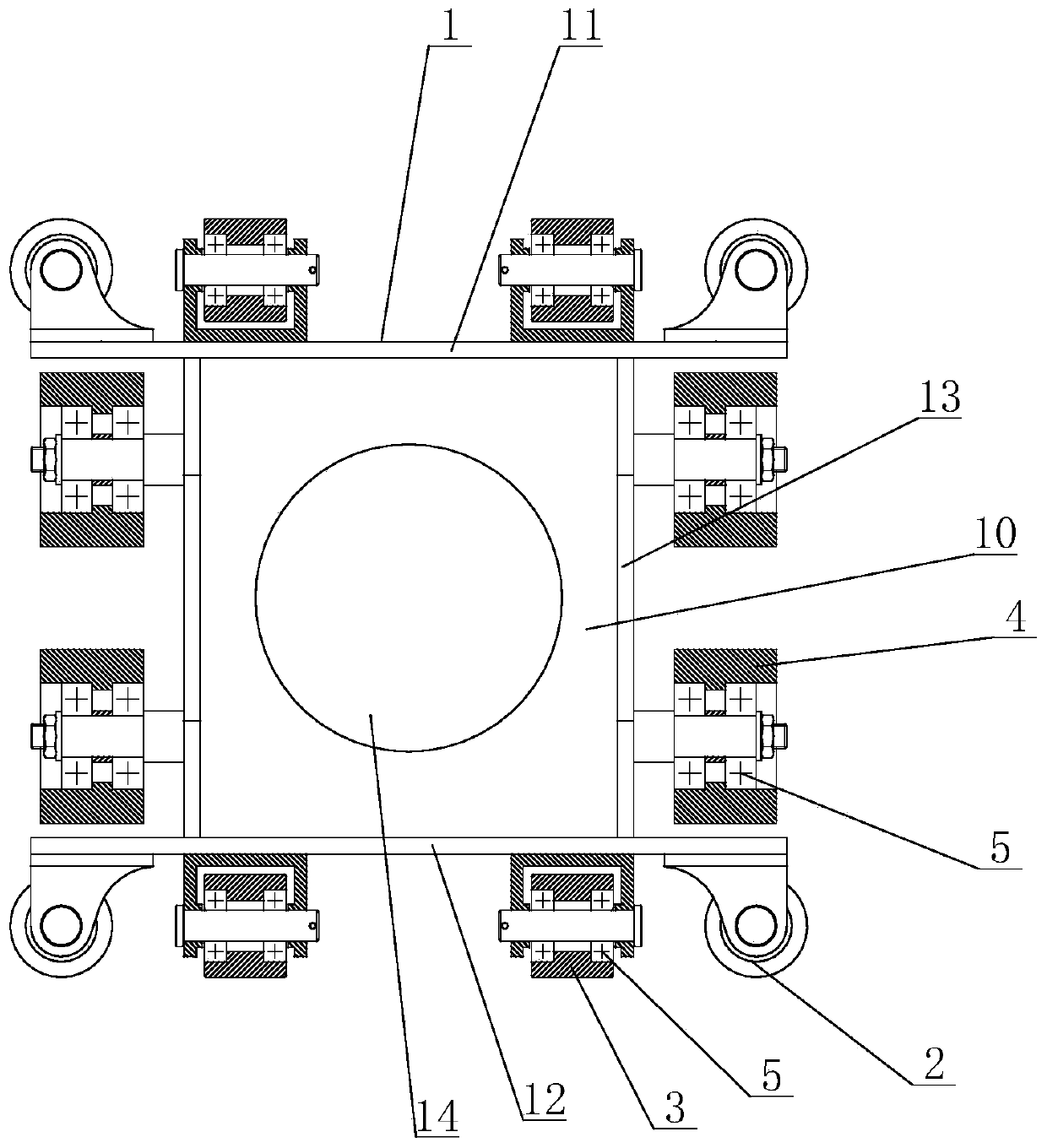

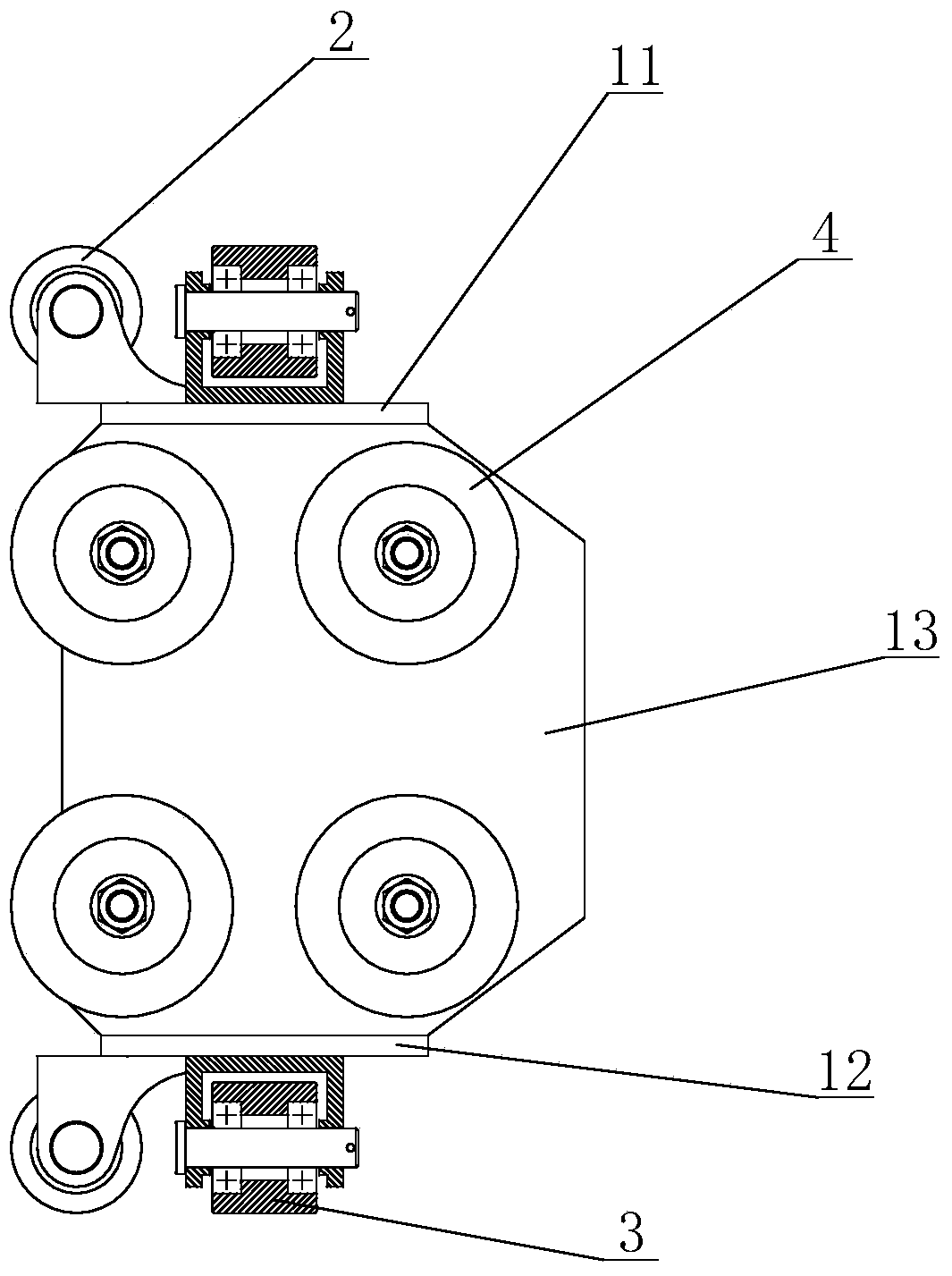

[0020] see figure 1 with figure 2 As shown, in this embodiment, a well-shaped slider trolley for electroplating driving includes a slider body 1 in the shape of an "I" as a whole, and the slider body 1 can be formed by welding steel plates or integral casting Either way, and the slider body 1 includes a square base 10, the upper and lower ends of the base 10 are correspondingly provided with an upper mounting plate 11 and a lower mounting plate 12, and the base 10 is There are two connecting plates 13 for connecting the slider body 1 to the boom at intervals, and several connecting holes are correspondingly opened on the connecting plates 13, and the structure size of the upper mounting plate 11 and the lower mounting plate 12 is Same, they are symmetrically arranged at both ends of the base 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com