Device for twisting compound silk thread

A technology for equipment and yarns, applied in the field of equipment for twisting multifilament yarns, to achieve the effect of improving flexibility, saving space, and closing machine spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

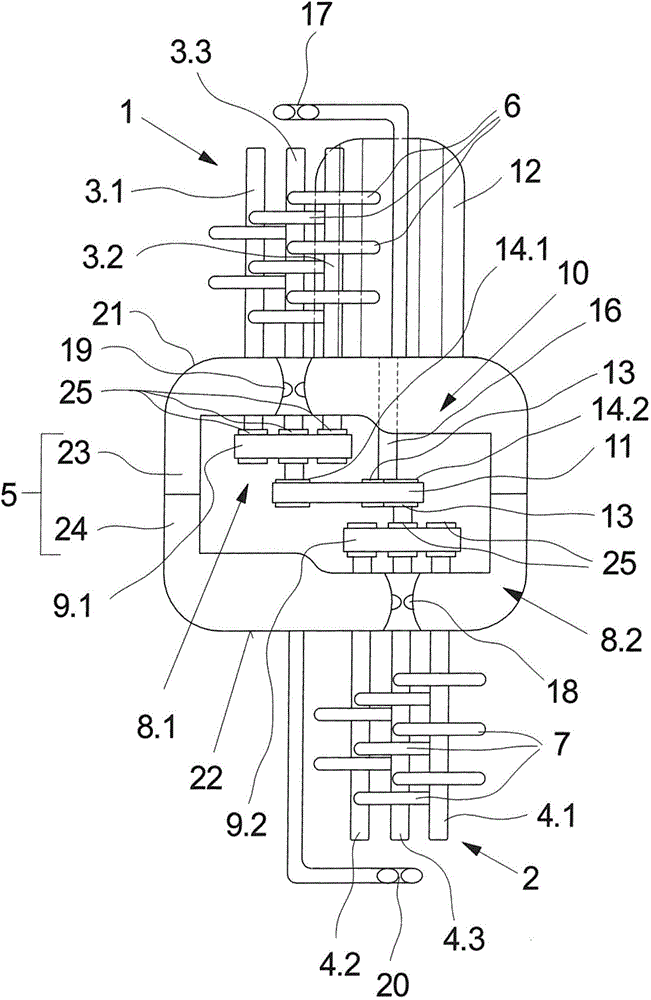

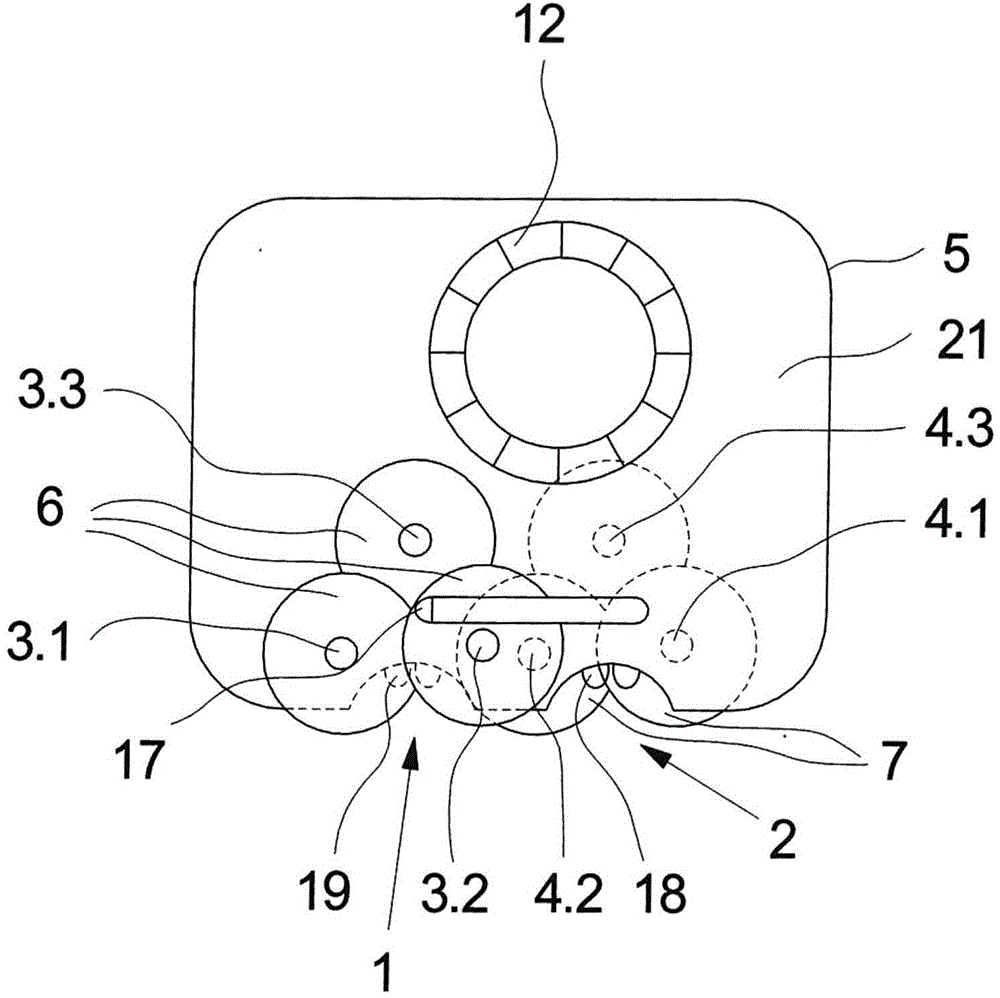

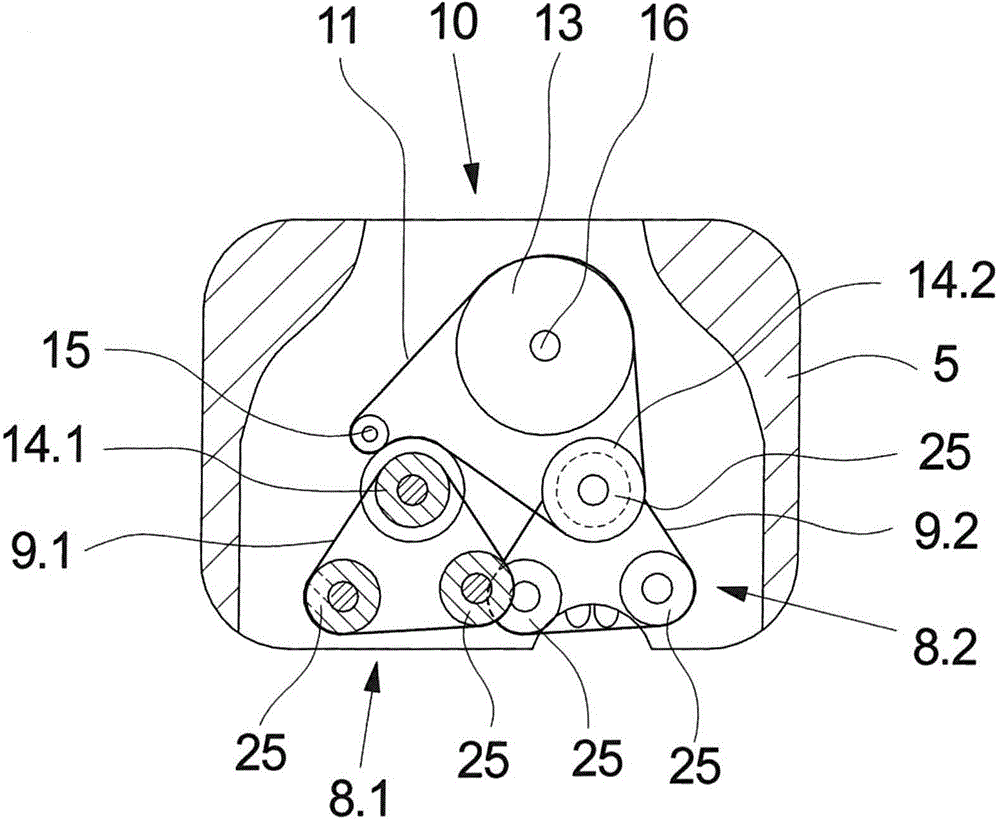

[0052] exist figure 1 , figure 2 and image 3 In , a first exemplary embodiment of the device for twisting multifilament yarns according to the invention is shown in various views. figure 1 The front view is shown schematically, figure 2 shows the floor plan schematically, and image 3 A cross section in the region of the drive is shown. The following description applies to all drawings as long as no specific reference is made to them.

[0053] The exemplary embodiment is configured as an assembly unit with an upper friction spindle arrangement 1 and a lower friction spindle arrangement 2 . The upper friction spindle arrangement 1 is arranged protrudingly on the upper side 21 of the spindle carrier 5 . The upper friction spindle arrangement 1 contains a total of three friction spindles 3.1, 3.2 and 3.3, which have a plurality of friction disks 6 spaced apart from one another and offset from one another on their peripheral surfaces. The friction discs 6 are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com