Solar power supply lift station water drawing pipe device with adjustable jointing speed

A technology of solar power supply and joint speed, applied in the parts of pumping devices for elastic fluids, variable displacement pump parts, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

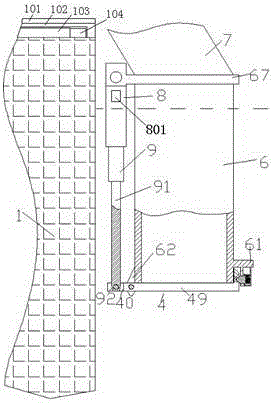

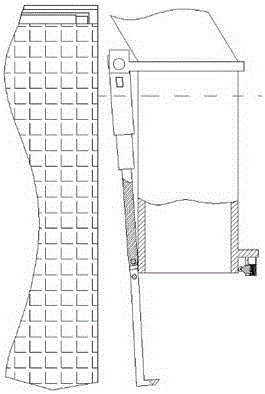

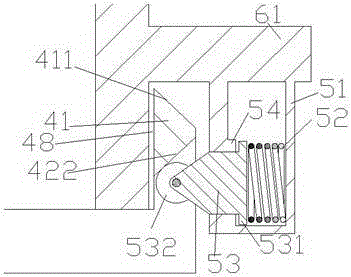

[0011] Combine below Figure 1-3 The present invention will be described in detail.

[0012] According to an embodiment, a solar-powered pumping station pumping pipe device with adjustable joint speed includes: an upper water pipe 7 , a lower water pipe 6 extending into the water, and fixedly installed at the boundary between the upper water pipe 7 and the lower water pipe 6 The fixed ring bracket 67 at the place, the fixed ring bracket 67 is hinged with a drive motor device 8 on the side close to the waterside wall 1, and the upper end of the threaded sleeve 9 with the screw rod 91 is connected with the drive motor device 8 ; Near the end of the lower end water pipe 6 is provided with a fixed lug 62 on the side close to the waterside wall 1, and the fixed lug 62 is connected with the protective closing plate 49 and the protective closing plate The protective cover device 4 of the driving protruding end 40 fixedly connected to the body 49 is hinged, and the hinged position is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com