Mechanical floating ball water filling valve

A mechanical, floating ball technology, applied in the direction of mechanical equipment, lifting valves, valve details, etc., can solve problems such as incompatibility, design structure and raw material performance constraints, and achieve novel design, compact structure, pressure resistance and water level control Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

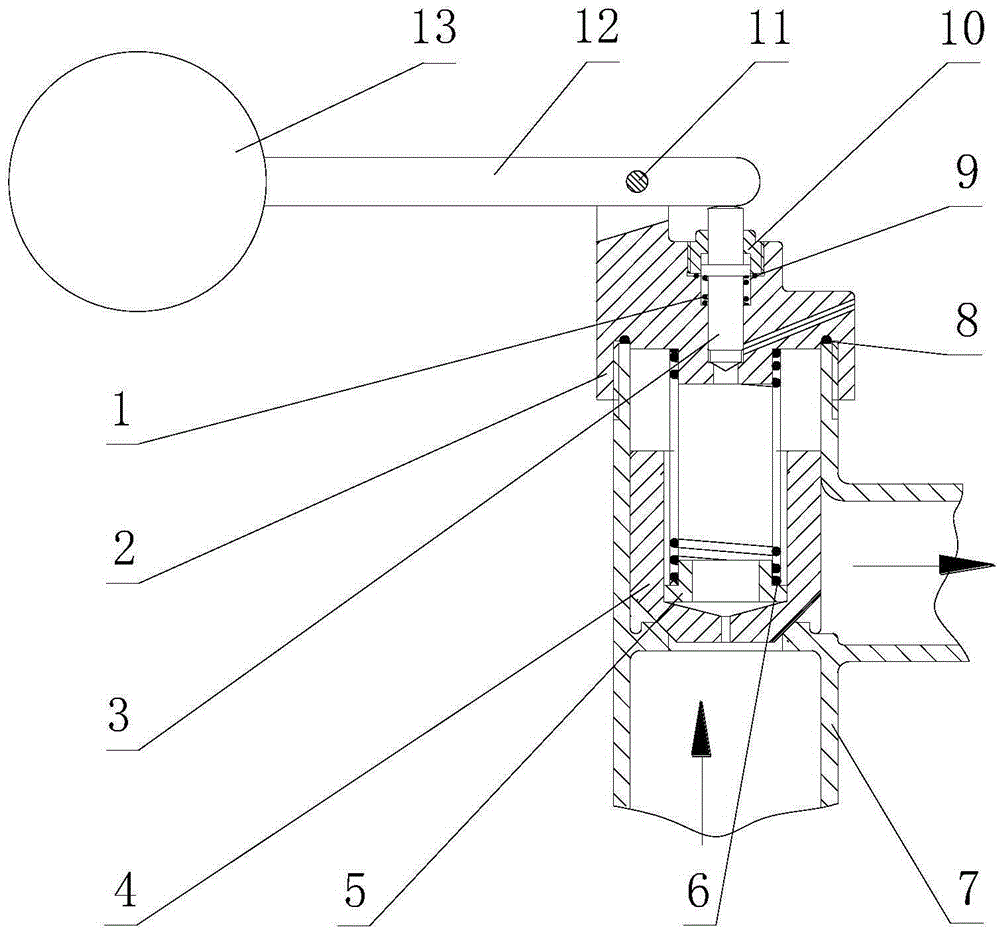

[0016] In this embodiment, refer to figure 1 , The mechanical floating ball filling valve includes a floating ball 13 and a lever 12. The floating ball 13 is installed at the front end of the lever 12, and the rear of the lever 12 is connected and fixed in an upper valve body 2 in a rotatable manner. The lower part of the valve body 2 is equipped with a lower valve body 7, and the lower valve body 7 is equipped with an inner valve 4; the inner valve 4 is provided with a spring seat 5, and the spring seat 5 has a positioning column. The positioning column is covered with a large spring 6, a large spring The upper and lower ends of the spring 6 are respectively connected to the lower end of the upper valve body 2 and the bottom of the spring seat 5; a needle valve 3 is installed in the upper valve body 2, the upper end of the needle valve 3 is in contact with the tail of the lever 12, and the lower end is connected to the upper valve body 2 The bottom of the inner valve 4 has a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap