Device for automatically detecting thickness of workpiece

A technology of automatic detection device and power device, applied in the field of mechanical processing, can solve the problems of inability to guarantee accuracy, time-consuming and laborious, inability to meet the requirements of workpiece accuracy, etc., and achieve the effect of improving production efficiency, good effect, and good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

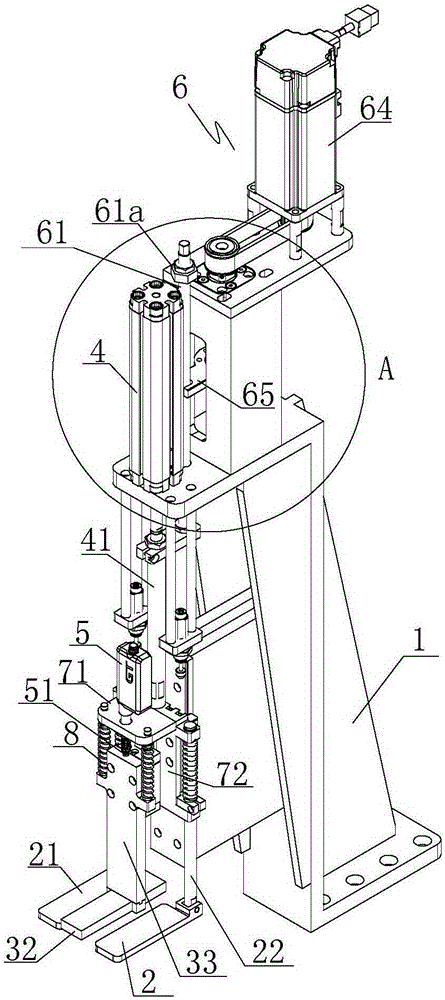

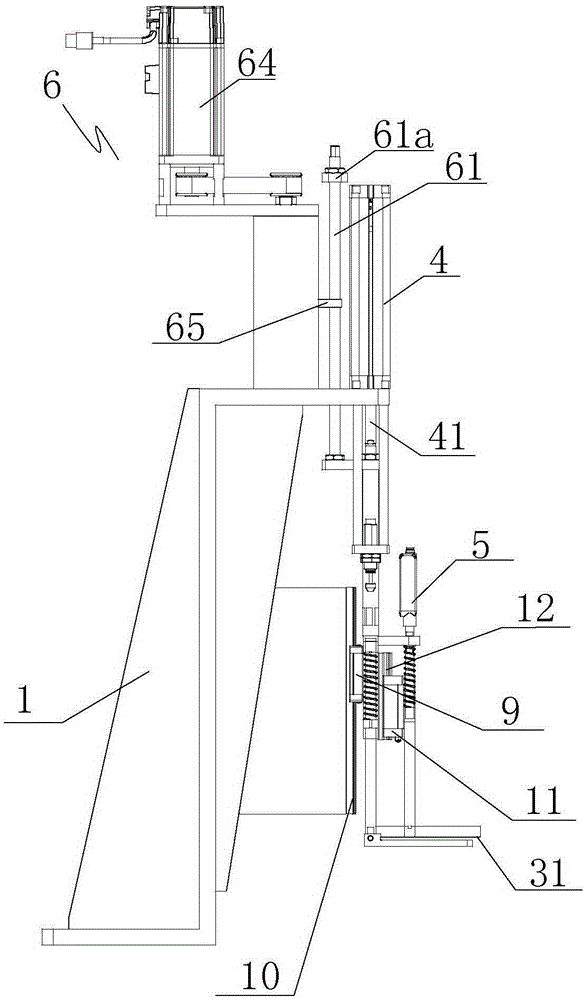

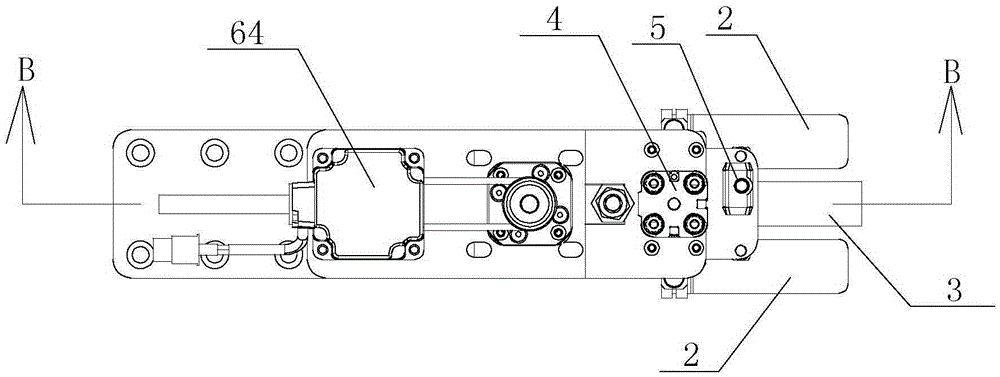

[0020] Combine below Figure 1-5 The present invention will be further described with specific embodiments, and the parts in the present invention that are the same as those of the prior art will be referred to the prior art.

[0021] Such as Figure 1-5 As shown, the automatic detection device of workpiece thickness of the present invention comprises frame 1, is provided with the presser foot 2 that is used for fixing workpiece when detecting on frame 1, and has the measuring part 3 of a flat measuring surface 31, so The presser foot 2 and the measuring piece 3 are respectively elastically mounted on the frame and can slide up and down under the action of the first power device 4, and a sensor capable of detecting the vertical displacement of the measuring piece is arranged on the measuring piece 5.

[0022] As a further optimization of the present invention, the present invention also includes an adjustment mechanism 6 for adjusting the height of the measuring surface 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com