Cosmetic composition containing an oily phase comprising a silicone elastomer in dispersed aqueous droplets and a particular surfactant

A technology of cosmetic composition and surfactant, applied in the field of skin care composition and/or cosmetic composition, to achieve the effect of non-greasy appearance and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A to Embodiment O

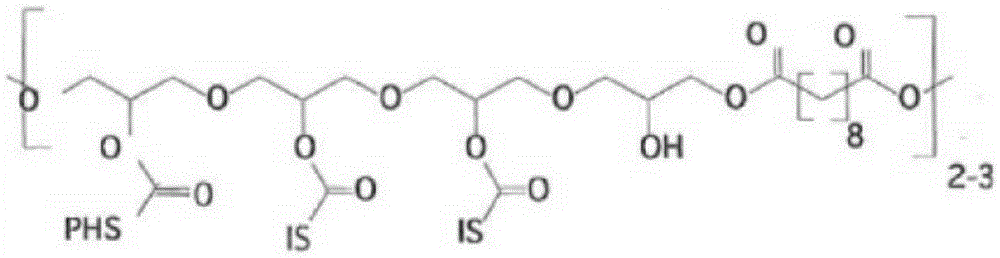

[0266] Example A to Example O: Effect of Surfactant Properties

[0267] Examples A to O show the effect of the structure of the surfactant on the dispersibility of an aqueous suspension of a silicone elastomer (BY29-119 from Dow Corning) in an oil phase.

[0268]

[0269] step

[0270] The ingredients of phase A were weighed out in a main beaker and then stirred (1600 rpm) using a Moritz stirrer while keeping at room temperature.

[0271] Then, phase B was added while stirring with a Moritz mixer (3500 rpm) until homogeneous.

[0272] result

[0273]

[0274]

Embodiment 1

[0275] Example 1: Water-in-Oil (W / O) Foundation

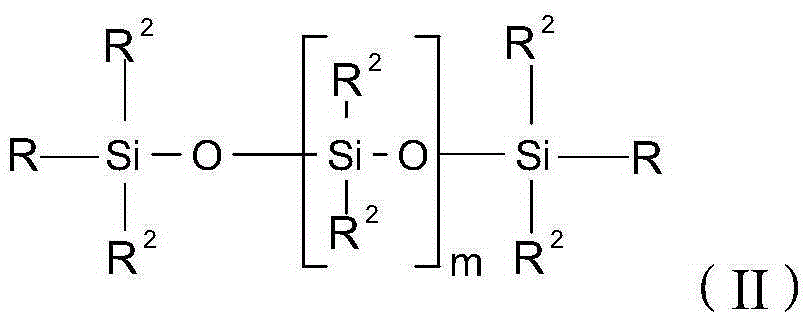

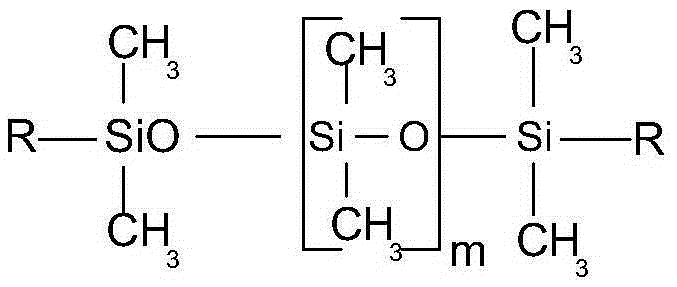

[0276] This example illustrates the first group of silicone surfactants of the present invention.

[0277] Therefore PEG-9 polydimethylsiloxyethyl dimethicone (KF6028 from Shin-Etsu), which can disperse an aqueous suspension of silicone elastomer (BY29-119 from DowCorning) in in the external oil phase of the emulsion.

[0278]

[0279] Step Example 1

[0280] The ingredients of phase A1 were weighed out in a main beaker and then stirred (375 rpm) with a Moritz stirrer while keeping at room temperature.

[0281] Phase A2 was prepared separately by milling the mixture of pigment and dodecamethylpentasiloxane three times in a three-roll mill.

[0282] Next, add phase A2 at room temperature and stir with a Moritz stirrer (375 rpm) until homogeneous.

[0283] Phase A3 was then added and stirring continued (500 rpm) using a Moritz stirrer.

[0284] Aqueous phase B was also prepared separately by weighing out glycerin and ...

Embodiment 2

[0293] Example 2: Water-in-Oil (W / O) Foundation

[0294] This example illustrates the second group of silicone surfactants of the present invention.

[0295] Bis-PEG / PPG-14 / 14 dimethicone (Abil EM97 from Evonik Goldschmidt) was therefore used, which allows dispersion of an aqueous suspension of a silicone elastomer (BY29-119 from Dow Corning) in the outer oil phase of the emulsion middle.

[0296]

[0297]

[0298] step

[0299] With embodiment 1.

[0300] sensory evaluation

[0301] In the half-face makeup test, a group of five women from the lab, aged 25 to 50, were asked to apply the foundation.

[0302] From this evaluation it appears that the foundation produces an even, consistent makeup result and can smooth the pores.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com