Method for manufacturing non-enveloped virus

A technology of enveloped virus and adeno-associated virus, applied to viruses, biochemical equipment and methods, viruses/bacteriophages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Inoculation of cells for production of rAAV vectors

[0073] In DMEM / F12 (manufactured by Gibco Corp.) containing 10% FBS (manufactured by Nichirei Biosciences Inc.), 293 cells were suspended. The suspension was inoculated into two 10 cm cell culture dishes (manufactured by Corning Inc.), and then in CO 2 Incubate overnight at 37°C in an incubator. Confirm that the cells are 70% confluent.

[0074] (2) Transfection of plasmids for production of rAAV vectors

[0075] The cells obtained in Example 1-(1) were transfected with 23.1 μg each of the pRC plasmid (manufactured by CellBiolabs, Inc.), pHLP plasmid (manufactured by CellBiolabs, Inc.) and pAAV-AcGFP plasmid encoding Rep protein and Cap protein of AAV type 2 (hereinafter referred to as AAV2), the pHLP plasmid contains adenovirus-derived E2A, VA and V4 sequences, and the pAAV-AcGFP plasmid is between the 2 ITRs of AAV2 Contains "CMV promoter sequence, sequence encoding AcGFP1 and PolyA sequence" as an expressi...

Embodiment 2

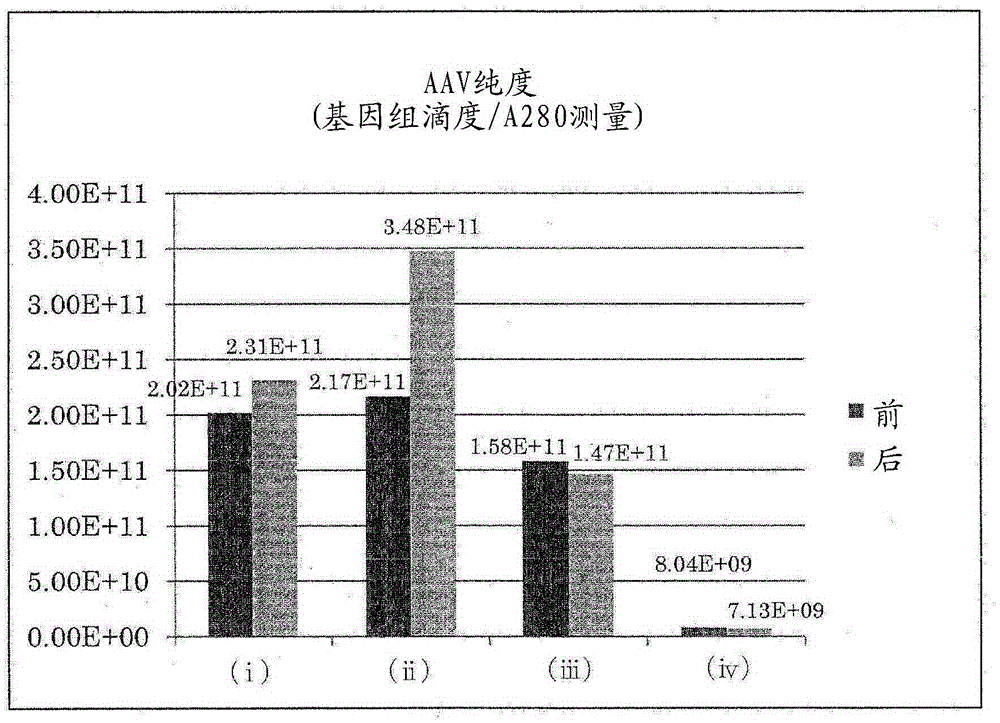

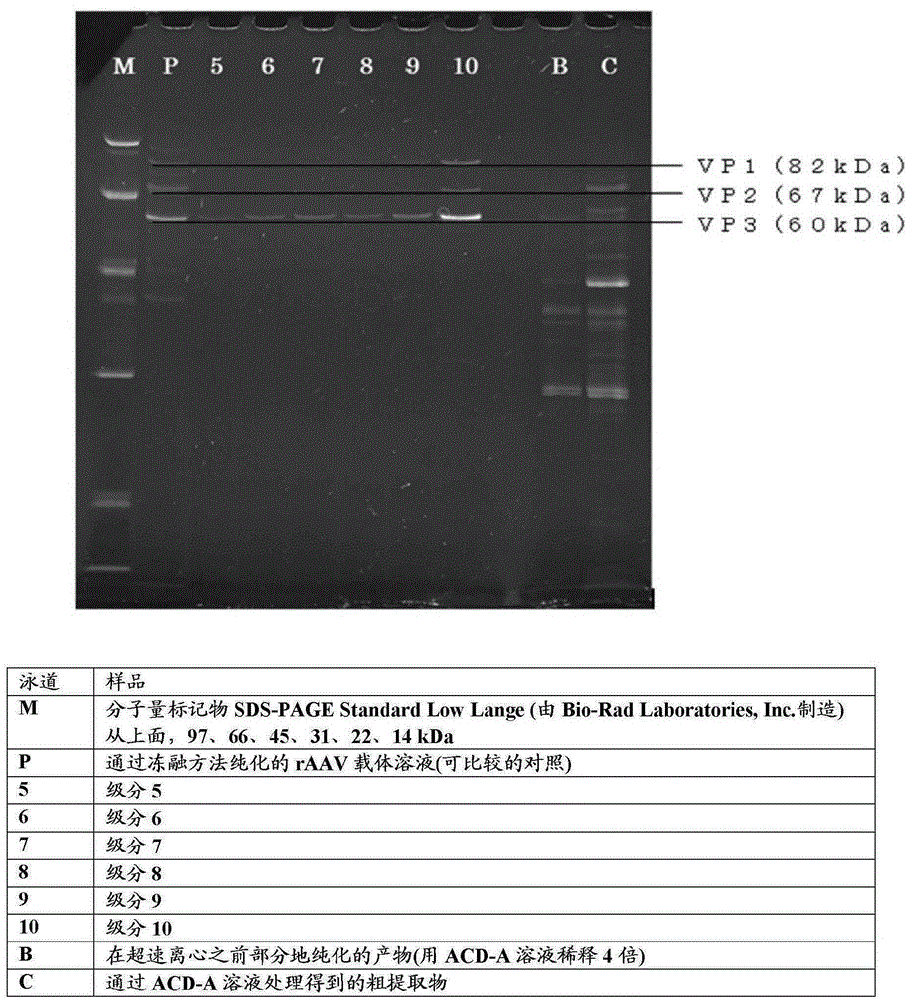

[0089] (1) Production of rAAV vector and preparation of crude extract with ACD-A solution

[0090] rAAV vector-producing cells were collected in the same manner as in Example 1-(1) to (3) except that CellBIND (registered trademark) T225 flasks (manufactured by Corning Inc.) were used as culture vessels and the related reaction system was scaled up. To the collected cell pellet, 10 mL of the ACD-A solution was added, followed by mixing with a vortex mixer for 15 seconds. The mixture was allowed to stand in a water bath at 37°C for 5 minutes, mixed again with a vortex mixer for 15 seconds, and then centrifuged at 4°C and 14,000 xg for 10 minutes. The supernatant thus obtained was used as a crude extract. As a comparable control, the freeze-thaw method (which is a routine extraction method for rAAV vectors) was performed on rAAV vector-producing cells cultured under the same conditions to prepare a crude extract, which was treated with BENZONASE (registered trademark) ( manufac...

Embodiment 3

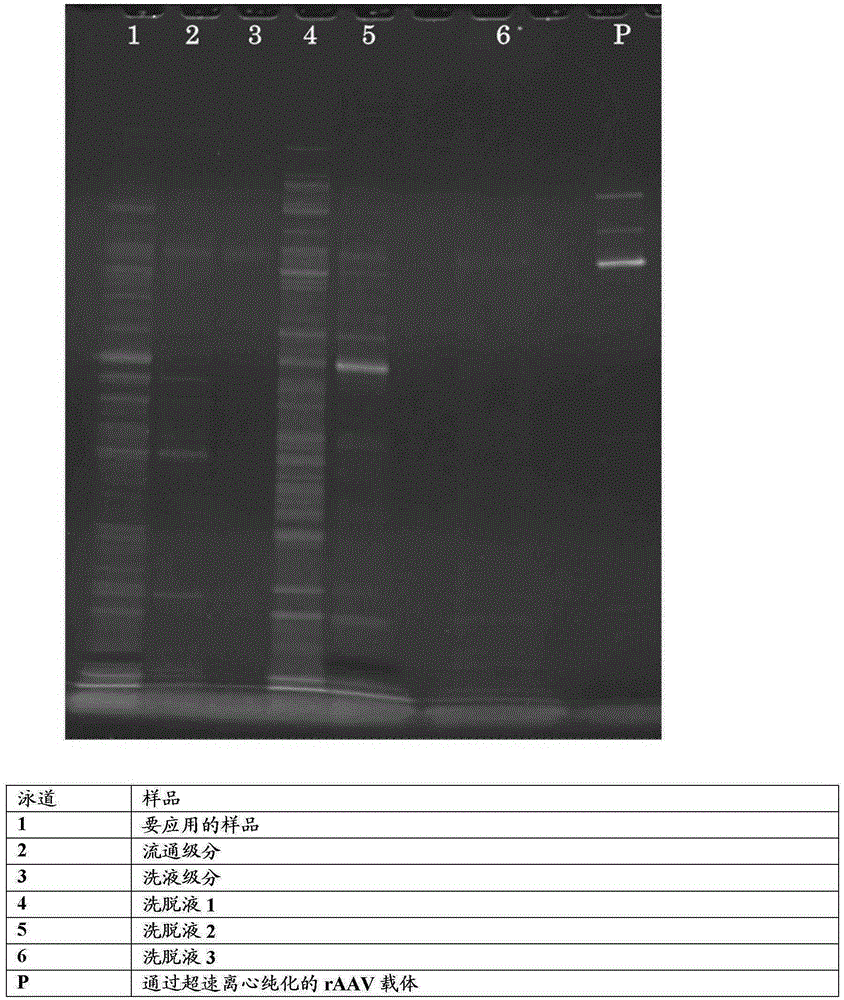

[0111] (1) Preparation of Crude Extract for Chromatography

[0112] Partially purified products were prepared in the same manner as in Example 2-(1) and (2). The partially purified product was diluted 5 times with water for injection (manufactured by Otsuka Pharmaceutical Co., Ltd.), and the diluted solution was used as a sample to be used.

[0113] (2) Purification by cation exchange chromatography

[0114] A syringe (manufactured by TERUMOCorp.), a posidyne filter having a pore size of 0.2 μm, and a cation exchange membrane (MustangS; manufactured by Pall Corp.) were connected in this order to set up a cation exchange chromatography device. Fill the syringe with 5 mL of ACD-A solution diluted 5 times with water for injection, and pass the solution through the filter and membrane at a flow rate of about 4 mL / min. Then, the syringe was replaced, and 10 mL of the sample to be applied prepared by Example 3-(1) was passed through the apparatus in the same manner as above. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com