An oven with a smoke exhaust device

A technology of smoke exhaust device and oven, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problem of burning, while other parts where a small part of the air flows may be undercooked, and the food is not heated evenly. problem, to achieve the effect of simple structure, easy cleaning, and adjustment of water locking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

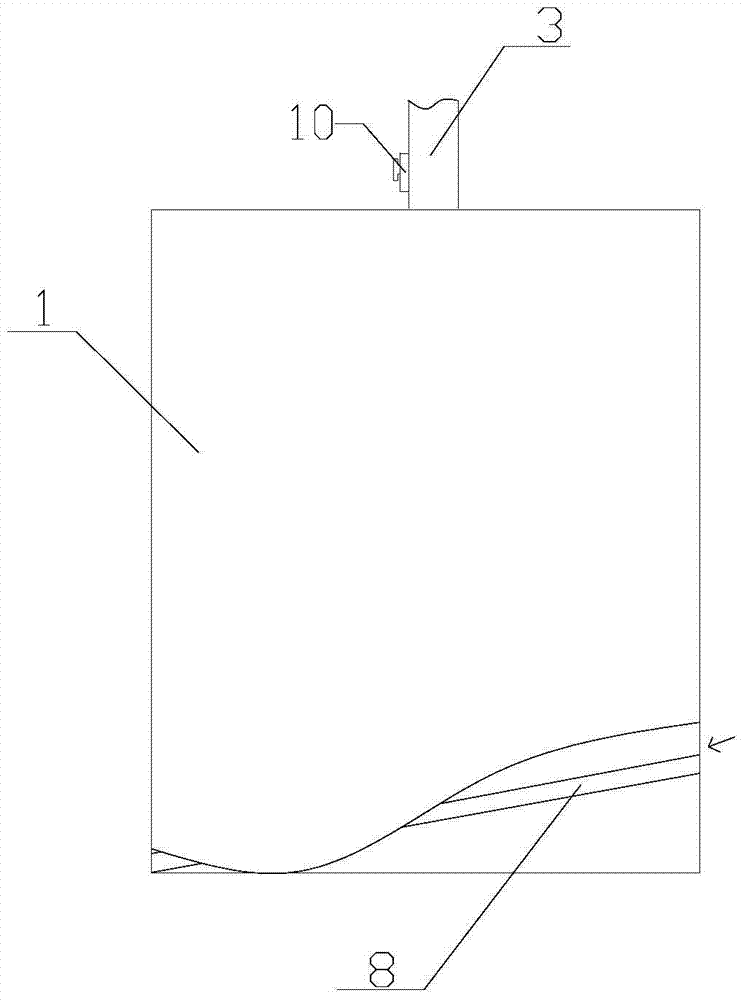

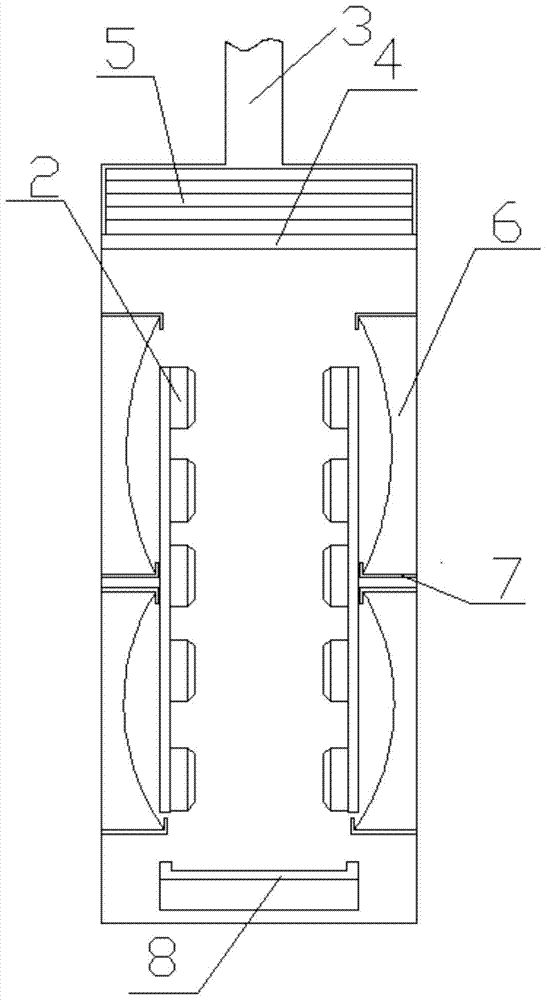

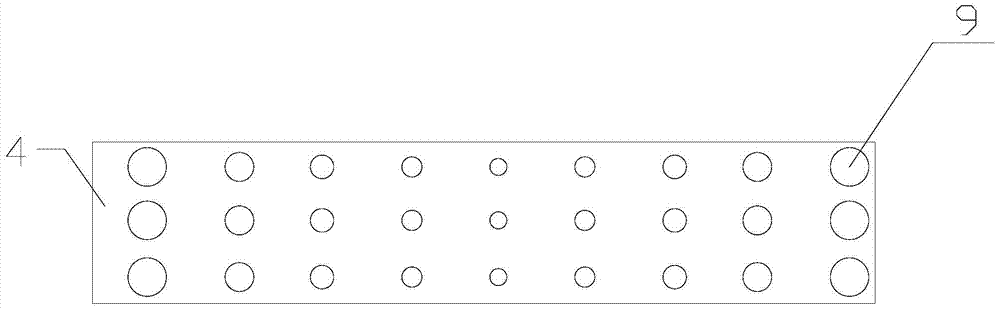

[0018] Such as Figure 1 to Figure 4 Shown: an oven with a smoke exhaust device, its main body is an oven 1 with a smoke exhaust device, the bottom of the oven 1 is provided with ventilation holes, and the inner sides of the two side walls of the oven 1 are respectively provided with heating elements 2 to form a heating area The smoke exhaust device includes a smoke exhaust channel 3 and a partition 4 arranged on the upper part of the oven box and communicated with the box, and the partition 4 is arranged in the oven box, between the heating area and the smoke exhaust channel 3 , the partition 4 is provided with several smoke exhaust holes 9, and the total area of the smoke exhaust holes in any unit area on the partition 4 gradually increases from the area close to the smoke exhaust channel 3 to the area away from the smoke exhaust channel;

[0019] Several smoke guide plates 5 are also arranged on the upper surface of the partition plate, and the vertical height from the up...

Embodiment 2

[0035] Such as Figure 5 Shown: the structure of embodiment 2 of the present invention is similar to the structure of embodiment 1, except for the smoke exhaust holes of the partition, when the apertures of the smoke exhaust holes 9 are the same, the distribution density of the smoke exhaust holes is from the area close to the smoke exhaust channel 3 to the The area away from the smoke exhaust channel gradually increases.

Embodiment 3

[0037] The structure of the third embodiment of the present invention is similar to the structure of the first and second embodiments, except for the smoke exhaust hole of the partition, when the aperture of the smoke exhaust hole 9 is different, the aperture of the smoke exhaust hole 9 is from the area close to the smoke exhaust channel 3 The area away from the smoke exhaust channel gradually increases, and the distribution density of the smoke exhaust holes gradually increases from the area close to the smoke exhaust channel 3 to the area away from the smoke exhaust channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com