Automatic mopping cleaner and mopping robot

A cleaning device and ground cleaning technology, applied in the direction of cleaning machinery, cleaning equipment, machine parts, etc., can solve the problems of uneven water spraying on the ground, re-pollution, and sewage residue on the ground, so as to avoid sewage residue, prolong service life, and spray water. even water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

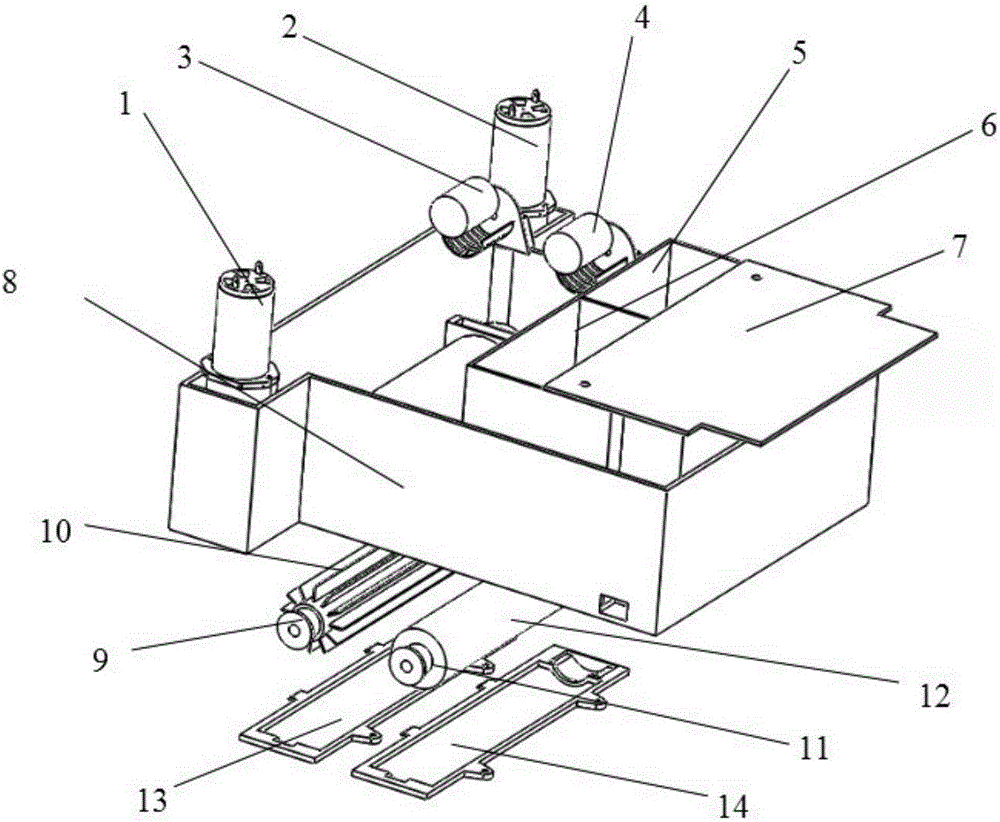

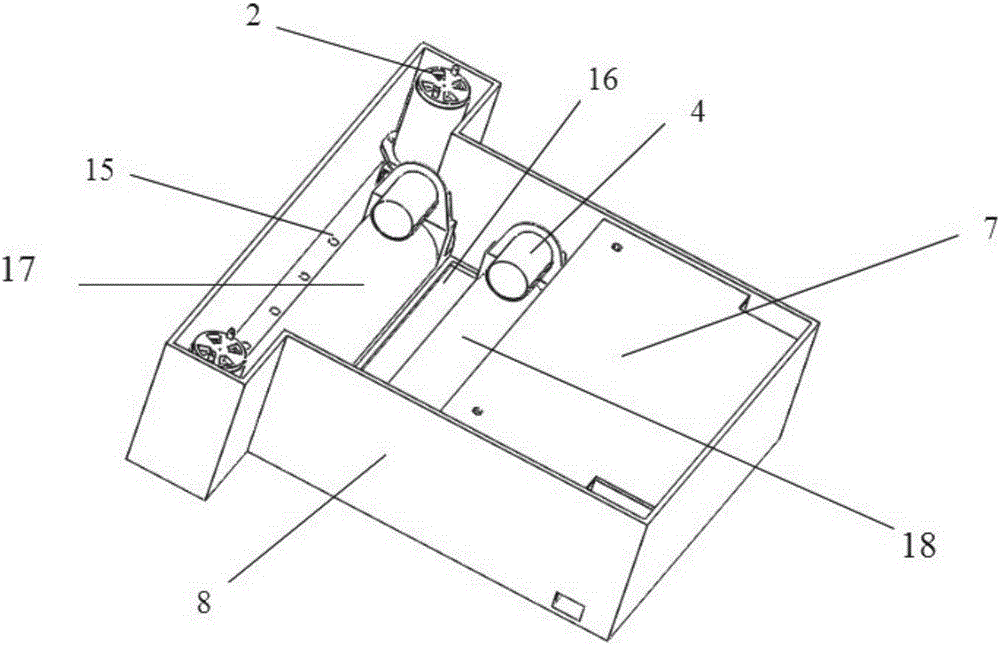

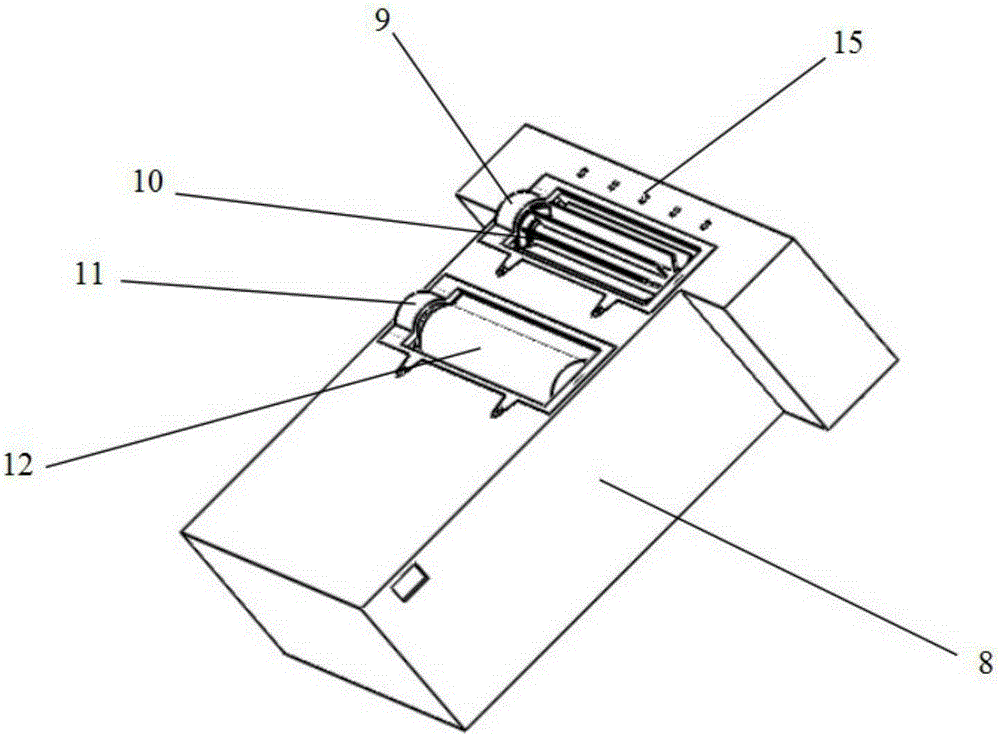

[0027] The automatic mopping and cleaning device provided by the embodiment of the present invention includes a water spray unit, a ground cleaning unit and a sewage recovery unit, the water spray unit is provided with a multi-pipeline drip nozzle, the ground cleaning unit is provided with a cleaning roller, and the sewage recovery unit is provided with a sponge roller , scraper and sewage area, the cleaning roller is installed in parallel in front of the sponge roller, the water spray unit wets the floor evenly and then the cleaning roller cleans the floor, the sponge roller absorbs the sewage generated by cleaning the floor, and the scraper absorbs the sewage on the sponge roller Collect in sewage sink.

[0028] Here, a hard brush is wound around the cleaning roller, and a sponge is wound around the sponge roller. The automatic mopping and cleaning device also includes an installation platform, the nozzle is located at the front end of the installation platform, and the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com