Roll system structure of straightening rolls with different roll diameters of aluminum-steel composite board and roll diameter determining method for roll system structure

A determination method and technology of straightening rolls, applied to the field of roll system structure and roll diameter determination of aluminum-steel composite plate straightening rolls with different roll diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The design method of the straightening roll system of the aluminum-steel composite plate with different roll diameters in this embodiment has the following steps:

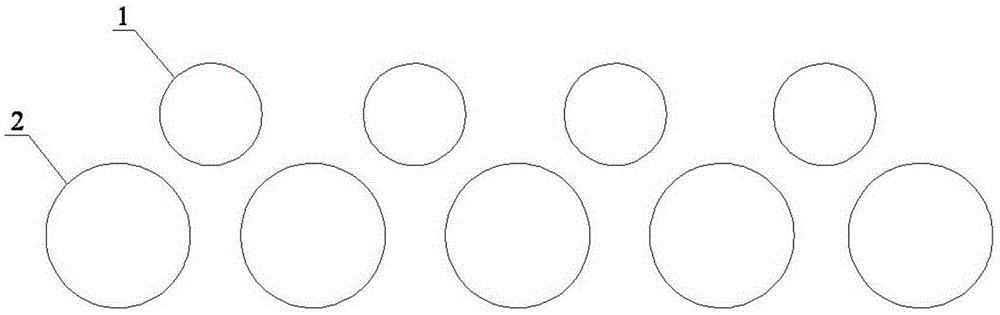

[0088] Such as figure 1 As shown, the roll system structure of a straightening roll with different roll diameters for an aluminum-steel composite plate in this embodiment includes a straightening roll assembly and a transmission assembly, and the straightening roll assembly includes a first straightening roll 1 and the second straightening roll 2, the number of the first straightening roll 1 and the second straightening roll 2 is multiple, and the roll diameter of the first straightening roll 1 is smaller than the roll diameter of the second straightening roll 2, A plurality of the first straightening rollers 1 are arranged at equal intervals along the horizontal direction, and a plurality of the second straightening rollers 2 are arranged at equal intervals along the horizontal direction, and the first stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com