Rotary type chain component transferring and processing platform

A processing platform and rotary technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as low production efficiency, difficult to remove waste, unsafe production process, etc., to achieve high production efficiency and high safety , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to the drawings and embodiments.

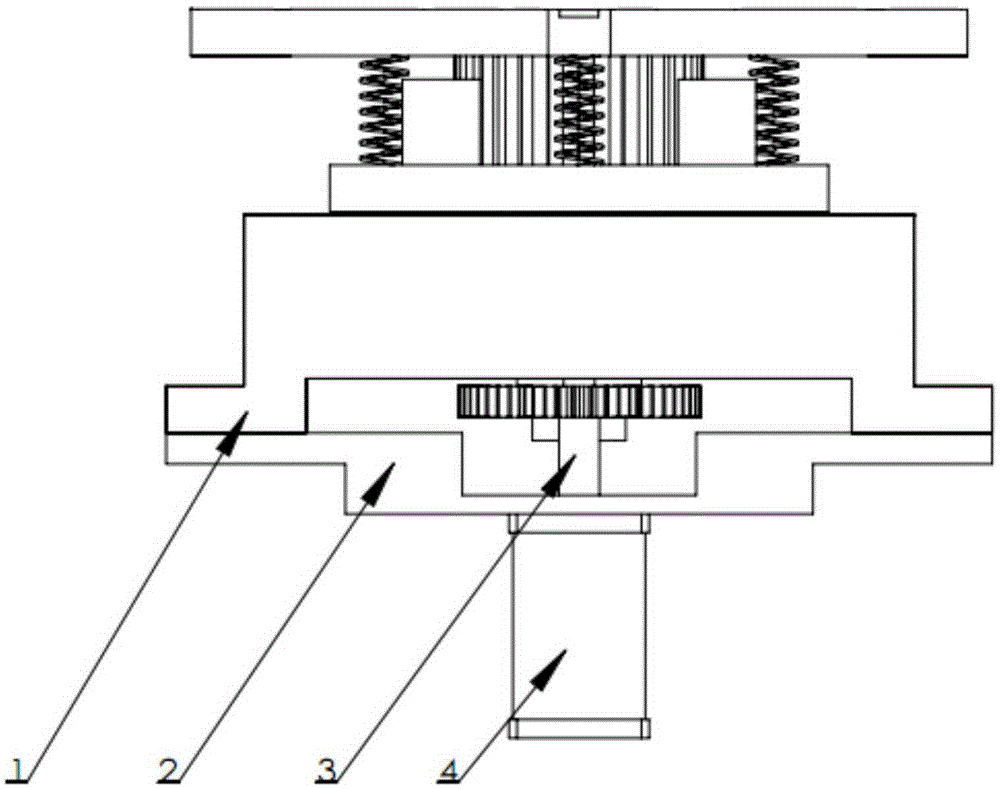

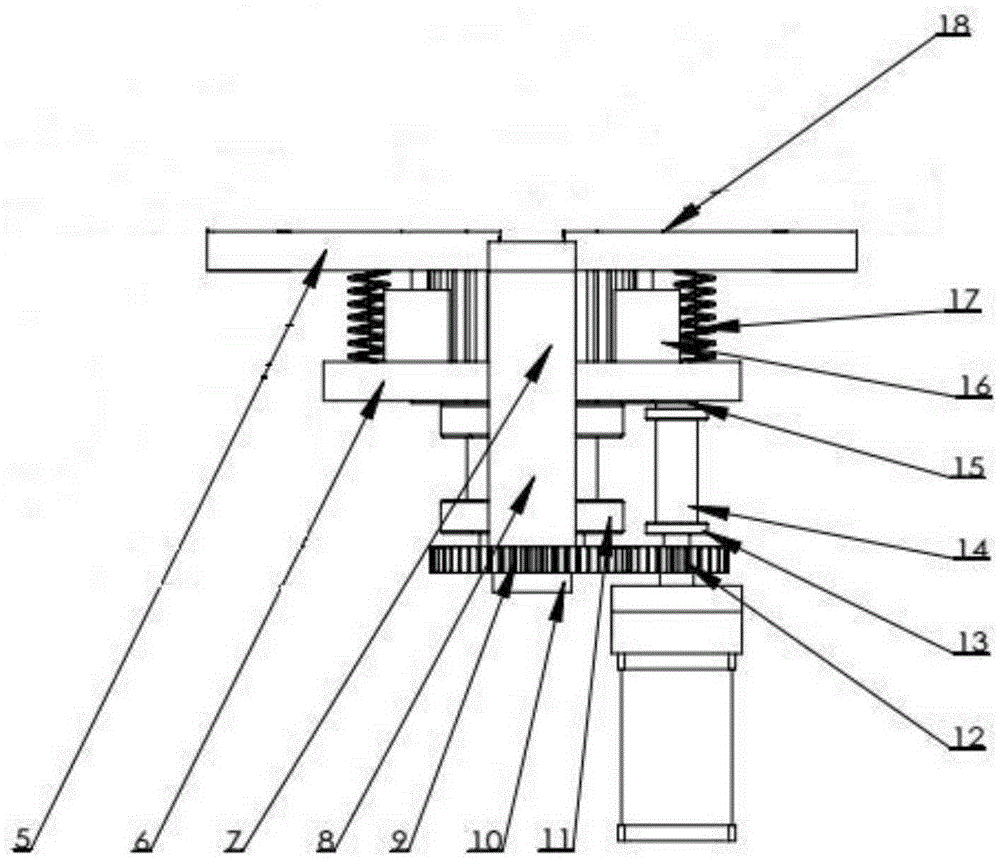

[0016] refer to Figure 1-Figure 2 , the present invention, the rotary chain parts transfer processing platform, comprising:

[0017] Power source, vertically arranged spline shaft 7, upper turntable 5, lower turntable 6, a plurality of springs 17, a plurality of limit blocks 16, the limit block 16 is made of polyurethane material, and the above-mentioned power source is used to drive the spline The shaft 7 rotates, the above-mentioned lower turntable 6 is set and fixed on the above-mentioned spline shaft 7, the above-mentioned upper turntable 5 slides and fits the above-mentioned spline shaft 7 through a flower shaft, and a plurality of the above-mentioned springs 17 are evenly distributed and the top is fixed on the bottom of the above-mentioned upper turntable 5, and the bottom is fixed on the bottom of the above-mentioned turntable 5. The ends are fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com